Next-generation fiber: Fluoride glass fibers enable high-power laser transmission in the mid-IR

FRANÇOIS SEGUIN, MOHAMMED SAAD, AND RUBEN BURGA

High-power infrared lasers, known for their use in industrial applications, are becoming more common in medical applications and especially in dentistry. Fluoride glass fibers are the logical power-delivery solution for use with mid-IR lasers (from 2 to 4 µm). These fibers show low Fresnel losses and low attenuation in the mid-IR; for example, a 2-m-long fluoride glass fiber transmits 90% of the input energy, 25% more than most commercial fiber. However, because technical challenges with coupling and delivery of laser light through fluoride fibers have limited their use, practitioners have continued to use laser sources at and below the holmium:YAG laser peak (2.1 µm) and traditional silica fibers (with transmission limits near this peak wavelength). Alternately, practitioners have used articulated arms with built-in optics and mirrors for higher-wavelength lasers.

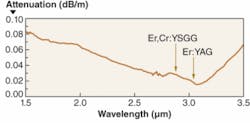

The industry wants a better solution because higher-wavelength lasers such as erbium (Er):YAG at 2.94 µm and Er, chromium (Er, Cr):YSGG at 2.78 µm are reportedly 2.4 times more effective in laser lithotripsy (the destruction of kidney stones through thermomechanical impulses) than the traditional holmium:YAG laser.1 In addition, the use of Er:YAG and Er, Cr:YSGG lasers is gaining acceptance along with traditional holmium lasers in the medical laser market, with commercial sales growing at a compound annual growth rate of almost 10%.2 Transmission requirements in the mid-IR region beyond 2.1 µm are not trivial, however, because standard fibers absorb highly in the region beyond 2 µm (see Fig. 1). Because this absorption can damage fiber, the use of higher-wavelength lasers requires light delivery through nonsilica glass and hollow fibers (see www.laserfocusworld.com/articles/292400). This research area has been discussed extensively in the literature and continues to be an area of interest for laser engineers, researchers, and academicians.3

As a result, several manufacturers have designed synthesized ZBLAN compositions of fluoride glass fiber, made of a mixture of zirconium, barium, lanthanum, aluminum, and sodium fluorides. The ZBLAN fiber offers low refractive index (n = 1.50) and flat attenuation in the region of 2.94 and 2.78 µm (see Fig. 2), which meets the need for high transmission at those wavelengths. Yet difficulties with attenuation and transmission failures have persisted that have limited its practical use to laboratory research.

New cladding, new results

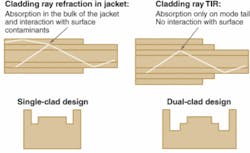

Recent investigations into the failure mechanisms of ZBLAN fibers under high-power conditions have confirmed that most failures are due to material imperfections, surface defects, and contamination, any of which can lead to mechanical and thermal damage.4 This is a critical point, as previous testing with fluoride fibers demonstrated an apparent sensitivity to power and consequently rapid transmission failures. The perception that ZBLAN fibers were fragile under high-power conditions resulted not from an intrinsic problem with fluoride fibers but with extrinsic and controllable conditions. In particular, the development of dual cladding using specifically selected materials compensates for the effect of evanescent wave propagation outside of the core fluoride fiber (see Fig. 3).

Traditional high-power silica fibers use a hardened cladding to improve their power-handling capabilities but a ZBLAN fiber with a step-index cladding design achieves similar results. In this way, any potential interaction with surface defects that could lead to thermal hot-spots is minimized. Furthermore, optimizing of the manufacturing process to eliminate inclusions has shown dramatically reduced transmission losses and increased power-handling capability. In fact, testing of a low-attenuation fiber (0.05 dB/m) with a high-power laser showed localized heating of no more than 0.5°C, whereas a fiber with a higher attenuation (0.4 dB/m) reached localized heating of 4.2°C under the same laser conditions.

In addition, the dual-cladding system confines the light within the light guide to permit the fiber to perform reliably under bending conditions as well as straight conditionsa necessary precursor for these fibers to be practical in medical and dental applications. Recent tests using a helium-neon laser at 3.39 µm compared the effects of bending with a single-clad 450 µm fiber and a 450 µm dual-clad fiber. Losses were dramatically lessened when dual cladding was used. At a bending radius of 4 cm, for example, losses in a dual-clad fiber were about 0.4 dB, whereas in the single-clad fiber they were 1.5 dB.

High-power delivery

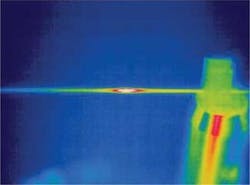

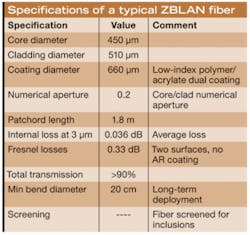

By eliminating the effect of inclusions and using a dual-clad design, ZBLAN fluoride fibers have been commercialized with high-power transmission of 90.7% over a 2 m length at various laser power settings after accounting for intrinsic losses and Fresnel reflection losses (see table). In practice, the fiber is typically mounted in a sleeved configuration with end connectors to accept and provide the output power from a pulsed laser. The end facet conditions must not allow inclusions, to prevent thermal hot spots and consequent rapid failures. Traditional cleaving procedures used for high-power silica fibers must be modified to compensate for the softer fluoride fiber and its sensitivity to facet mechanical damage. Typical guidelines for coupling a pulsed laser to the fiber should be followed. As discussed in academic literature, the numerical aperture of the source should be confined to 0.08 and the ratio of the source focus spot to the core diameter of the fiber should be maintained at 70%.

As can be expected, maintaining the bend radius of the fiber higher than the radius specified by the manufacturer for a specific diameter will prolong the life of the fiber. Under ideal test conditions, a 2 m length of a high-power ZBLAN fiber has transmitted over 98% of the light after accounting for the end-face Fresnel losses of 7%.

High-power ZBLAN fibers have been tested in excess of 1.5 million shots without failures using a Er,Cr:YSGG pulsed laser at 2.78 µm. They have demonstrated the capability to handle more than 10.3 MW/cm2 of power and peak fluences of 1530 J/cm2. As pulsed lasers in the mid-IR region have proven to be more effective in medical and dental procedures, the recent development and commercialization of high-power ZBLAN fibers is enabling the accelerated adoption of pulsed lasers.

REFERENCES

1. K.F. Chan et al., Proc. SPIE 3914, 198 (June 13, 2000).

2. K. Kinkade, BioOptics World, 31 (January 2008).

3. J. Harrington, Infrared Fibers and their Applications, SPIE Press, Bellingham, WA (2004).

4. F. Séguin et al., Proc. SPIE BiOS, Paper 6852-12 (2008).

Tell us what you think about this article. Send an e-mail to [email protected].

FRANÇOIS SEGUIN is the vice president of engineering, MOHAMMED SAAD is the chief technology officer/founder, and RUBEN BURGA is the vice president of sales and marketing at IRphotonics, 627 McCaffrey, Montreal, Quebec, Canada H4T 1N3; e-mail: [email protected]; www.irphotonics.com.