Mid-IR Optics: Chalcogenide nanofeatures on calcium fluoride bring metalens technology to the mid-IR

Metamaterial optics, often in the form of a nanostructured metasurface, have the potential to be transformative for precision optics. Existing metasurface optics have been fabricated that operate in the visible and near-infrared (near-IR) regions. The mid-IR, because of its different set of optical materials, has been more difficult.

While metasurfaces for the mid-IR have been fabricated, the designs are typically centered on the use of metallic nanostructures, which have high-enough optical losses that they can only be used in reflection, not in transmission. Creating metasurface lenses operating in transmission requires the use of dielectrics for the metamaterial nanostructures.

Scientists at the University of Electronic Science and Technology of China (Chengdu, China), the Massachusetts Institute of Technology (MIT; Cambridge, MA), and East China Normal University (Shanghai, China) have now created high-efficiency, diffraction-limited mid-IR metasurface optics using chalcogenide-alloy nanofeatures lithographically fabricated on calcium fluoride (CaF2) substrates (both materials are dielectrics).1 The wideband properties of chalcogenide and CaF2 enable optical designs to be created anywhere within a wide portion of the mid-IR. Such optics could help to simplify and lighten the weight of mid-IR sensing instruments for the detection of biomolecular and chemical signals.

Huygens’ meta-atom design

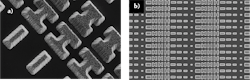

The devices are based on a so-called two-component Huygens’ meta-atom design invented by the researchers. Each meta-atom has an H shape that functions as a pair of dielectric resonators separated by an air gap and connected by a dielectric bar. The bars have resonances in both polarizations—the resonances are tuned by varying the dimensions of the dielectric bars. Simulations showed that transmission >85% could theoretically be achieved.

To see what could be achieved experimentally, the researchers first deposited 650-nm-thick films of lead telluride (PbTe) chalcogenide onto CaF2 substrates optically polished on both sides. The array of meta-atoms was then fabricated using a double-layer electron beam resist lift-off process, producing PbTe structures with a sidewall angle of 68° (accounted for in the meta-atom design). The optic was designed to function similarly to a blazed-grating diffractive beam-deflector (see figure). Because the array has subwavelength spacing, there is no diffraction in a direction perpendicular to the mimicked blazed grating. The experimental diffraction efficiency reached 60% for this device.

A flat lens functioning as a cylindrical lens (focusing in only one axis) with a focal length of 0.5 mm and a numerical aperture (NA) of 0.71 was also fabricated. This device operated at the diffraction limit over a 5.1–5.4 µm wavelength region and had a longitudinal chromatic aberration (focal shift as a function of wavelength) of -0.11 µm/nm, agreeing with the predictions of the simulation. While the NA of the lens was too high to allow proper measurement of lens focusing efficiency (defined as optical power at the focal spot/line divided by the total incident power) in the setup, the optical transmittance of 80% along with the observed low scatter led the researchers to believe that the focusing efficiency was close to 80%.

An aspheric metalens was also constructed, which has a 1 × 1 mm square aperture and a focal length of 0.5 mm at a 5.2 µm wavelength. This lens had a Strehl ratio >0.8 in the 5.11–5.405 µm wavelength range.

“This kind of metasurface can be made using standard microfabrication techniques,” says Tian Gu, one of the researchers. “The manufacturing is scalable.”

REFERENCE

1. L. Zhang et al., Nat. Commun., doi:10.1038/s41467-018-03831-7 (2018).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.