Incorporating news from O plus E magazine, Tokyo

TOKYOSeiko Instruments has developed software for the large-scale integration design environment that predicts super-resolution lithography output.

Optical lithography involves exposing a surface covered by a patterned mask. The resolution is limited by diffraction effects andunless certain "tricks" are usedit is impossible to achieve finer resolution than the wavelength of the incident light. One of the tricks used in super-resolution lithography is the phase-shift mask. By controlling the phase of the light that goes through the mask openings, interference effects can be created that cause the light intensity distribution to have a higher resolution than the wavelength of the light.

When such super-resolution techniques are used, however, numerous imperfections that cannot be predicted during the mask-design stage can creep into the output. For instance, dimensions might be slightly off or process margins may become narrower. Therefore, after the mask is designed, it is important to run simulations to predict the light-intensity distribution across the surface. Such simulation products are already available, but they can only be used by lithography process professionals.

Commercial software is now able to accurately predict the output of lithography that relies on a phase shift mask to extend the resolution limit.

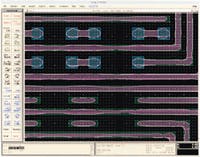

A new programSX-9000 LILEis packaged in conjunction with the layout editor used in Seiko's existing ultra LSI design system, as well as a light-intensity simulator (see image). Thus the design environment and the output prediction environment are integrated. The predicted output can be sent to an editor in the form of curves. The designers can then look at the predicted output and make adjustments based on these data.

The light-intensity simulator uses a fast-Fourier-transform algorithm. By revisiting the algorithm, a tenfold increase in the speed has been achieved while maintaining the same standard of analysis. This product can handle both conventional masks and phase-shift masks. Adjustable parameters include wavelength, opening shape, distortion, and focusing imperfections.

Courtesy O plus E magazine, Tokyo