Using a photorefractive polymer composite as a medium, researchers at Stanford University (Palo Alto, CA) are building video-rate optical systems in which energy is transferred from one laser beam to another as the two beams write a volume hologram. Such a setup can be used for amplifying image intensity or for detecting the motion of an object (also called novelty filtering).

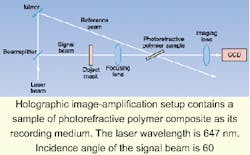

The chosen material is PVK:AODCST:BBP:C60, in which PVK is a polymer host matrix, AODCST is a nonlinear optical molecule (specifically, alkyl-oxy-dicyanostyrene), and the C60 (or buckminsterfullerine) absorbs light and produces mobile holes. Synthesized by Robert Twieg of Kent University (Canterbury, England), AODCST has an index of refraction that depends on the strength of a local electric field. A sample of the polymer composite is placed in a hologram recording setup in which an object mask is inserted in the signal beam (see Fig. 1). The signal beam passes through a converging lens; the sample is placed 1 cm beyond the focus at the intersection of the signal and reference beams. A photodetector measures time response; alternatively, a second lens projects a real image onto a charge-coupled-device (CCD) camera.Electron holes are generated in the sample wherever the light is bright. The holes move slightly under influence of an applied electric field, producing a spatially varying electric field that changes the index of refraction of the AODCST in proportion to the field and creates a hologram. "But this hologram is not for optical storage, because the charges are not stored for a long time," explains Stanford researcher W. E. Moerner. "Rather, it is useful for optical-processing applications."

When the reference beam is turned on, signal intensity reaches a maximum in less than 100 ms and then settles to a lower value. The researchers' interest lies in video-rate processing in which frame duration is 33.3 ms; tests at such a rate show a net image amplification of 37 at an applied electric-field strength of 77 V/µm. The high speed of the composite is probably due to a close match of the highest occupied molecular levels of AODCST and PVK, say the researchers.

A direct demonstration of image amplification at video rates was done of an image of the number 5 at an applied electric-field strength of 69 V/µm, a signal-beam intensity of 0.5 mW/cm2, and a reference-beam intensity of 1 W/cm2 (see Fig. 2). The image was amplified by at least a factor of 9.4 (the CCD camera itself had a dynamic range of only 10).

For a demonstration of video-rate novelty filtering, the researchers reversed the applied electric field so that energy was transferred from the signal beam to the reference beam, causing image intensity to fade to almost nothing after a few hundred milliseconds. Moving the image a fraction of a millimeter makes it reappear; if the movement is stopped, the image fades again. The response of the polymer composite has a fast risetime and a somewhat slower approach to steady state, so the image appears more quickly than it disappears.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.