Saturable Bragg reflectors simplify modelocking

BRUCE CRAIG and ARND KRUEGER

There are a number of advantages to modelocking a continuous-wave (CW) laser. The resultant ultrafast pulses provide temporal resolution in the femtosecond or picosecond domain, and the high peak power is useful for driving a host of nonlinear optical effects, including multiphoton absorption and harmonic generation of shorter wavelengths.

A newly matured device, the saturable Bragg reflector (SBR), now offers a simple method of modelocking. The concepts of the SBR were originally investigated in 19921 and patented by laser physicists at Lucent Technologies (Holmdel, NJ) in 1997.2 Spectra-Physics (Mountain View, CA) has been developing novel, robust SBR designs for a number of years and received a license to produce commercial SBR-based lasers in 1997.

As its name suggests, the SBR depends on saturable absorption.3 Before the advent of the Ti:sapphire laser, saturable dye absorbers were used extensively as intracavity devices to modelock lasers. Under CW power levels, the device absorbs incident laser light, increasing the loss of the cavity. But under higher peak-power illumination, the dye temporarily bleaches, reducing the loss of the cavity. Key requirements for a saturable absorber are that its absorption is strong at the peak wavelength of the laser emission, that the loss when bleached is low, and that the device has a fast recovery time.

As long ago as the 1980s, engineers realized that a semiconductor quantum well could function as a saturable absorber, but a device with the appropriate properties proved elusive. This changed in the early 1990s when Lucent engineers showed that a multilayer mirror coating incorporating one or more quantum-well layers could be used to modelock a laser. A quantum well provides saturable absorption over a spectral band, defined by its physical dimensions, and features low losses.

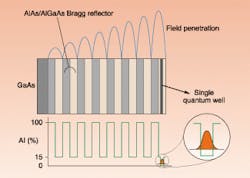

In one particular mirror configuration, the substrate material is GaAs, with alternate layers of AlAs and AlGaAs forming a multilayer Bragg mirror or quarter-wave stack (see Fig. 1). Neither AlAs nor AlGaAs absorbs at the Ti:sapphire laser peak (800 nm). A thin (few microns) layer of AlGaAs is buried in the topmost layer of this stack, acting as a quantum well with a strong absorption at 800 nm. One of the advantages of this particular design is that it does not require any dielectric-mirror layers and can therefore be mass-produced in a single process using a molecular-beam-epitaxy or metal-organic chemical-vapor-deposition reactor.

SBR performance and benefits

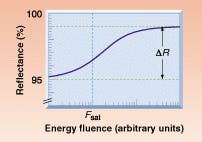

At low laser intensities, a typical SBR has a reflectance of 95%, whereas under modelocked intensities the reflectance rises to almost 99% (see Fig. 2). Because of the multipass nature of a CW laser, this 4% change is more than sufficient to induce strong modelocking.SBR modelocking is particularly attractive for use in commercial lasers. The underlying Bragg reflector has a relatively limited wavelength range of high reflectance, and so this design is perfect for fixed-wavelength applications. It is a passive modelocking technique that is remarkably simple, using a single optical element. Also, this technique requires no electronics or special starting mechanisms. Unlike earlier passive techniques, SBR modelocking is self-starting, self-sustaining, and free from dropouts. Moreover, SBR modelocking can be used over a wide range of pulse durations and output-power levels. And extensive testing in our R&D laboratory and at beta test sites shows this technology has a long life expectancy.

Simple Ti:sapphire laser

In recent years, commercial Ti:sapphire laser technology has seen a growing emphasis on simplicity and rugged design. The goal is to provide reliable, easy-to-use modelocked lasers for both laboratory and industrial applications. This trend is exemplified in one design in which the Ti:sapphire oscillator and a solid-state pump laser are packaged in a single, compact sealed box. The rugged simplicity of SBR modelocking makes this an ideal technique for modelocking such a laser.

The first commercial ultrashort Ti:sapphire laser product to use an SBR was exhibited last May at the Conference on Lasers and Electro-Optics (CLEO 2000) in San Francisco, CA (see Fig. 3). In addition to the SBR, this fixed-wavelength laser avoids the use of dispersion-compensation optics by using negative-dispersion cavity mirrors. This approach yields a pulse duration of less than 30 fs and an average output power of 300 mW; this short pulse duration translates into peak powers as high as 125 kW. The typical spectral bandwidth is 30 nm.High-power Nd:YVO4 laser

The potential uses for SBR technology are not limited to Ti:sapphire lasers. By using different semiconductor layers and an appropriate quantum-well design, the SBR can modelock virtually any CW laser in the near-infrared spectral region. We have found that the SBR not only offers the advantage of simplicity but also results in improved performance. Specifically, because Nd:YVO4 has a much narrower spectral bandwidth, the deeper cavity modulation produced by an SBR is required to generate shorter pulsewidths. In the laboratory we have achieved 10-ps pulses, compared to the typical value of 30-100 ps produced by other modelocking techniques. This is an important advantage, because the shorter pulse duration and higher peak power translate directly into higher harmonic-conversion efficiencies.

Recently, we have demonstrated infrared powers greater than 50 W and green (532 nm) output greater than 38 W—both record values for quasi-CW Nd:YVO4 lasers. This will allow the development of commercial high-power ultraviolet (UV) 355- and 266-nm laser systems. Because of the high pulse-repetition rate (80 MHz), such lasers can be used as CW sources in most applications such as computer and microelectronics manufacturing, fiber-grating production, materials processing, and medicine.

REFERENCES

1. U. Keller et al., Opt. Lett. 17, 505 (1992).

2. W. H. Knox, US Pat. # 5,627,854 (1997).

Bruce Craig is marketing manager and Arnd Krueger is product manager, industrial and scientific lasers, at Spectra-Physics, Mountain View, CA 94043; e-mail: [email protected] and [email protected].