Diffractive optical elements (DOEs) allow wavefront shaping that cannot be accomplished as easily by ordinary reflective or refractive optics. More important, DOEs can be realized on simple flat substrates and volume-manufactured by replication. Hence, studying their utility for laser resonators is worth some effort. However, the proper adjustment of two diffractive mirrors to form a laser resonator turns out to be fairly difficult because both lateral and angular position must match their mutual diffraction cones.

Now, a research group at the Fraunhofer Institut für Angewandte Optik und Feinmechanik (IOF) and at the Friedrich-Schiller-Universität (both of Jena, Germany) has overcome this drawback by creating both resonator mirrors as diffractive structures on a common flat substrate so that no mutual adjustment of those mirrors is required.1 Instead, a plane third reflective mirror, installed to receive the beam from and transmit it to the diffractive mirrors in a folded resonator, is to be adjusted only like a plane mirror in an ordinary Fabry-Perot interferometer, for which lateral adjustment is uncritical (see Fig. 1).

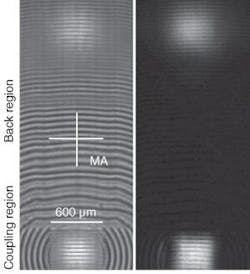

An Nd:YAG rod of 5-mm length and diameter is mounted immediately before the folding mirror and pumped by a laser-diode module emitting at 810 nm. Lasing builds up at 1064 nm in a folded beam, the radiation in the backcoupling leg being returned by a diffractive structure designed to provide a super-Gaussian beam shape of order m = 20 (m = 2 provides the ordinary Gaussian shape) and to form a quadratic beam cross section at the outcoupling part of the diffractive structure. The complete diffractive structure is seen when the laser is pumped slightly above threshold (see Fig. 2).The outcoupling region is an almost linear grating of 600-µm width and period 40 µm that diffracts light in the first order back to the laser rod under half (0.65°) the folding angle. To feed the fundamental mode, higher modes are suppressed by surrounding the outcoupling diffractive structure with an annular blazed phase grating. The higher orders are deflected from the optical axis, missing the laser active rod and amplification; as a result, a mechanical aperture (to be adjusted for the suppression of higher modes) is not necessary.

The structure of the back-reflecting region is a superposition of a specially designed diffractive phase function and a linear grating. The complete diffractive structure was a replica from a lithographically produced master, blazed to support radiation along the folded beam, and gold-coated to provide sufficiently high reflectivity to allow continuous-wave lasing. The fringes in the outcoupled beam appear in the near field and can be overcome by optical means, which are currently under investigation. This folded setup allows thorough investigation of diffractive optics for resonators without complicated adjustment.

REFERENCE

1. A. Büttner et al., Appl. Phys. B 81(5) (2005).

Uwe Brinkmann | Contributing Editor, Germany

Uwe Brinkmann was Contributing Editor, Germany, for Laser Focus World.