Researchers at the Electronic Instrumentation Laboratory at the Delft University of Technology (Delft, The Netherlands) have developed a new technique for light scanning by use of viscoelastic-based deformable phase-diffraction gratings.1 By controlling the spatial period of the grating by mechanical stretching, its diffraction orders can be angularly altered.

Traditionally used for light deflection and splitting, diffraction phase gratings have applications in spectroscopy, holography, interferometry, and fiberoptic interconnects. For ultrafast-laser applications, phase gratings ensure high phase stability compared with an ordinary beamsplitter. For laser-beam scanning and deflection, acousto-, electro- or magneto-optical, or hybrid spatial light modulators can be used to create controllable diffraction elements. But now, a new low-cost method of controlling the parameters of a diffraction element by mechanical deformation has been demonstrated.

The researchers first fabricate master molds with a triangular or a rectangular grating-element profile by etching an aluminum layer deposited onto a silicon chip. A two-component viscoelastic silicone elastomer is then deposited in the master mold and cured for eight hours at 60°C until polymerization is complete. The elastomer has low optical loss and perfect homogeneity and can be reversibly elongated by 40% of its initial length. A rectangular viscoelastic deformable grating made from this process was measured by white-light interferometry and found to have a spatial period of 32 μm and a groove height of 0.62 μm. A triangular-profile grating had a spatial period of 4.46 μm and a height of 0.59 μm. In the unstressed state, the thickness of both samples was measured at 0.4 mm, with a refractive index of 1.43.

High diffraction efficiency

By fixing one end of the grating to an optical mount equipped with a digital caliper, the researchers characterized its diffraction performance with the grating in a normal state and also stretched. A 633‑nm He-Ne laser was spatially filtered with a 50-μm pinhole and launched onto the viscoelastic phase grating. Even for a relative elongation (change in length of the grating divided by initial length of the grating) of 18% from an unstretched length of 18.68 mm to a stretched length of 22.03 mm, the diffraction efficiency of the +1 and -1 orders was hardly affected. Good correspondence of the actual profile parameters of the fabricated gratings (diffraction efficiency of 16.5%) with those specified while the master molds were made (diffraction efficiency of 18%) shows that specially designed grating profiles optimized for deflection into a single order combined with an elastic substrate should permit wide scanning angles with high diffraction efficiency.

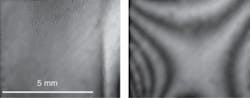

Elongation of the viscoelastic gratings does result in thinning and deformation in the transverse direction, causing optical distortions in the transmitted laser beam. Using a Mach-Zehnder interferometer with a 1:1 sample-imaging system, the researchers compared interferometric images of the central region of a rectangular-profile grating in the normal state and under stretch (see figure) to estimate the magnitude of the distortions. While the elongation was shown to cause aberrations in the wavefront of the transmitted beam, the calculated Strehl ratio (the peak intensity of the aberrated beam divided by the peak intensity of an ideal beam) for a 5‑mm-diameter beam in the first diffraction order was 0.53, whereas for a 1‑mm beam it reached 0.99. According to the researchers, these Strehl ratios are acceptable for the majority of applications for which these viscoelastic gratings would be used.

The frequency response of the grating was measured by clamping one end of the grating to an optical mount and attaching the other to a voice coil. The mechanical response of the voice coil was measured independently to factor out its contribution to the overall grating response. It was determined that the optical efficiency and response time of the viscoelastic deformable grating scanner was comparable to or better than those of micromachined devices for light scanning.

Researcher Aleksey Simonov says that the future direction of their work is to produce stretchable Echelle gratings to obtain the highest diffraction efficiency (theoretically 100%) in only one diffraction order that can be used as a laser light scanner. “Another direction of our research is to implement viscoelastic optical elements (not only gratings) for adaptive-optics applications; in particular, aspherical-shaped elements that can be used for the intraocular correction of human eye aberrations,” he says.

REFERENCE

1. A. N. Simonov et al., Optics Lett.30(9) 949 (May 1, 2005).