Most displays are big and conspicuous. Head-up displays (HUDs), on the other hand, make the data conspicuous while hiding the display equipment. A HUD is any display that presents data without blocking the user’s view. The first market for HUDs was use for military pilots. These systems are the most standardized, and tend to be a unit mounted on the ceiling of the cockpit with a pull-down dedicated panel. But technical advances in electronics, optics, and software over the past decade are allowing HUDs to be used in new commercial applications.

In a HUD, the user doesn’t look directly at the display device that converts the electrical signal to an image. Instead, lenses and mirrors maneuver the image from the display to a combiner, which is ideally the only part of the system within the user’s field of view. The data from the display is superimposed on the user’s field of view at the combiner.

The display, once a cathode-ray tube (CRT), is now more likely to be a backlit liquid-crystal display (LCD)-although a host of designs are in use and still being developed. The revolution in microdisplays, which are now ubiquitous on products from PDAs to cell phones to hand-held games, benefits HUDs because these microdisplays also tend to be optimized for mobile use: small, light, cheap, robust, and more energy-efficient.

In theory, the combiner can be a half-silvered mirror, a dielectric coating, or a holographic optical element (HOE). If the combiner were a planar half-silvered mirror at a 45° angle between the display and the viewer’s eyes, then the system would be relatively simple (and much like the design of 1980s video-arcade games), but the mirror would degrade the user’s view past the display. Many dielectric coatings, similarly, tend to change the color of the view. Holographic optical elements offer several advantages for systems that can bear the cost. Depending on the sophistication of the HOE, it can adapt to nonplanar combiners. Some combiners are dedicated parts of the HUD (such as in aviation systems), while others are integrated into an optical element used primarily for other purposes (such as the windshield in cars). The panel can be at distances ranging from mere inches to feet away from the viewer’s eyes.

In the air

Head-up displays aid military pilots-who have to keep track of a plethora of data and make decisions quickly-by overlaying flight, navigation, attack, and other information over the pilot’s forward field of view. Early systems used CRTs. The systems, which have shrunk over time, are usually installed in the ceiling of the cockpit and now have a clear flip-down screen with a holographic combiner.

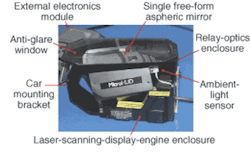

FIGURE 2. A compact laser-based HUD doesn�t use a conventional display at all; instead, a diode laser is scanned in two dimensions to create the lines of a monochrome display.

HUDs for commercial aircraft are also common now, and are especially useful in assisting with instrument-only landings. Because of the cost (hundreds of thousands of dollars), only the pilot is usually provided with a HUD, but some companies are choosing to incorporate HUDs for copilots as well. Because civilian pilots have more freedom of movement in the cockpit than military pilots, a civilian system’s “eyebox” (the area in which the user’s eyes must be located to see the display) must be larger.

Several air-traffic-management groups have looked into providing HUDs to assist air-traffic controllers. As part of their jobs, controllers have to integrate and organize data obtained by both looking out tower windows and looking down at electronic diagrams, which can mean switching quickly between views that can have wildly varying lighting conditions.

On the road

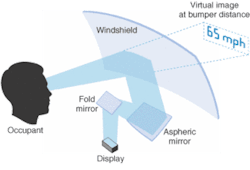

In cars, HUDs in the dashboard reflect an image off fold mirrors (which are often aspheric), finally reflecting off the windshield to the driver. The entire system must be inexpensive (under $500, according to analyst Kimberly Allen of iSuppli; Santa Clara, CA), robust, and the systems need to be manufacturable without much additional labor. The eyebox location must be adjustable for different drivers. The system also cannot be polarization-dependent, given the popularity of polarizing sunglasses.

As with pilots, the benefit of the HUD is that the driver doesn’t need to look away from the road to look at dash-mounted displays. The drawback of the systems is that they must not be so fascinating that they distract the driver from the road, or so bright that they interfere with the driver’s vision.

The display is usually near or just above the driver’s view of the hood of the car, where it doesn’t interfere with the view of traffic. On many systems, the image is also projected to appear to be beyond the hood of the car, to reduce the change in the distance at which the driver’s eyes are focused (see Fig. 1).

Head-up displays were first introduced into cars in the late 1980s-and were soon withdrawn. Those systems used incandescent light bulbs, which were hot and power-hungry. Neither the optics nor the electronics of those first-generation systems could provide the benefits that users demanded. Since then, advances in displays and multicolored light-emitting diodes (LEDs) have improved the resources available for HUDs. If any car HUD system can be considered typical, it would be an LED-backlit LCD microdisplay combined with several reflective optical elements.

Several high-end cars now have HUD options available, costing well over $1000 each, including some Cadillac, Corvette, Pontiac Grand Prix, and BMW 5 and 6 Series models. Some cars (including Cadillacs and Hummers) have optional thermal-IR imagers mounted on the front that use HUDs. Car systems often incorporate a light sensor to monitor the amount of light around the car, brightening the display during daylight hours and dimming it at night.

Automotive-HUD manufacturers have become more sophisticated about the shape of the windshields. The windshield is the final optical element in the system, and small changes in the shape of the windshield can create large differences in the operation of the HUD. DuPont (Wilmington, DE), which makes a polymer interlayer for windshield glass, developed a specialized wedge shape designed for HUDs that reduces the ghost images arising from the display reflecting off the second surface of the windshield.

No conventional display components are used in a laser-scanning system that is being developed by Microvision (Bothell, WA). The MicroHUD, uses a laser and the company’s MEMS-based laser-beam-steering technology in a system aimed at the auto market (see Fig. 2). Tom Sanko, Microvision’s vice president of marketing, explains that the single laser diode is cooler and more efficient than ganged LEDs used to backlight a display. “It enables an extremely high contrast ratio,” he notes. “There is no hazy glow on the windshield like you have with backlit LCD systems; all you see is the display content, such as navigation arrows, speed, and so on.”

“The MicroHUD will work with any windshield,” says Sanko. “We have the ability to shape the beam and predistort and displace the video.” This capability eases installation labor.

Head-mounted and see-through

The MicroHUD is actually an extension of Microvision’s already commercialized head-mounted HUD. The company’s first product, the Nomad Expert Technician System, includes a 4.5-oz HUD, either mounted on the brim of a baseball cap or integrated into a headband, providing a monochrome SVGA image. The system includes a wireless Windows CE-based computer that connects to the dealership’s computer system. Without leaving the vehicle, a service technician can use the belt-mounted control unit and the HUD to access electronic repair manuals, work orders, vehicle history, parts inventory, or e-mail.

FIGURE 3. An early demonstration version of a helmet-mounted HUD incorporates a large display.

ASK Innovation Limited (Poole, Dorset, England), a newcomer to the HUD market, is developing an LCD-based HUD with an array of phosphor-coated LEDs as a light source. The efficiency of the system has been optimized, according to Andrew Smith, managing director. “We can now run the light-engine part of the system at 12-V DC, drawing only 120 mA of current,” says Smith. This allows the system to be powered by a standard gel battery pack, making the HUD capable of being head or helmet mounted (see Fig. 3). “One key market application,” says Smith, “is for firefighters who can now be fitted with an IR-based system within the fire hat.”

Meanwhile, Motion Research (Seattle, WA) has commercialized the SportsVue, a much smaller HUD that can be mounted on normal motorcycle helmets. A base unit mounted on the motorcycle sends gear, rpm, and speed data via a wireless link to the AAA-battery-powered display unit. The system is available for under $350-orders of magnitude less than the much more complex and larger-display aerospace HUDs. This summer the company plans to release a version for bicyclists that displays current and average speeds, pace arrows, and trip and total distance information.

Eyeglass-mounted displays

Even smaller than visor-mounted systems are displays that mount on eyeglasses. These systems use an opaque mirror off to one side, which is small enough to barely obstruct the field of view. In practice, such displays provide the same benefits to the user as HUDs.

FIGURE 4. A VGA display is reflected into the viewer�s eye from a mirror mounted on a pair of eyeglasses.

Glasses-mounted HUDs made by MicroOptical (Westwood, MA) are based on a tiny VGA color-filter microdisplay provided by Kopin (Taunton, MA), backlit with an LED. Once displayed, the image travels through a clear optical pipe, hits a small mirror, and bounces back into the user’s eye through a lens (see Fig. 4). The control box for the system runs on a camcorder battery and includes typical video controls, as well as a control that allows the user to specify the apparent distance of the display.

The system can accept image data in standard video or computer formats (RGB analog video signal or VGA output). This has the interesting effect of decoupling the HUD technology from presentation issues that are critical in applications where the system is part of a larger piece of equipment.

MicroOptical is selling these displays, explains Mark Basler, vice president, for a variety of military, medical, and industrial applications. Military applications often use it to allow users to see into the IR. Homeland-security and police groups are also using the displays.

An FDA-approved medical application introduced last summer presents surgeons with a patient’s vital signs. Typically, a surgeon looks away from the patient at a monitor across the room. The company claims this system is safer for the patient, saves the surgeon time during surgery, and is selling quite well. The displays thus far have been monocular, presenting the image to just one eye. Within the first half of 2005, says Basler, the company expects to launch binocular (although not stereo-vision) systems.

MicroOptical is also developing wireless applications using Bluetooth. The benefits of untethering users are clear, but the tradeoffs include short range and loss of bandwidth. “The display could present text or pictures, but not video,” says Basler. Further into the future, Basler expects the company to be selling systems that eliminate the reflective mirror by building it into the lens of a pair of glasses.❏