DAVID KEMP AND ROD SCHUSTER

Applications for ultrafast laser pulses in the femtosecond domain continue to expand and diversify. Current uses include multiphoton microscopy, subcellular microsurgery, and three-dimensional micromachining. Generating and manipulating femtosecond laser pulses requires the ability to limit pulse lengthening due to group velocity dispersion (GVD) and spectral distortion. In practical terms, accomplishing this requires specialized and novel optical coatings and components.

Pulsewidth, spectral bandwidth, and GVD

Increasing the duration of an ultrafast laser pulse can have two negative consequences depending upon the application: a direct lowering of the temporal resolution of the test or experiment being performed and a reduction in pulse peak power. These consequences affect any application that depends on nonlinear phenomena, such as multiphoton imaging and CARS spectroscopy.

With ultrafast laser pulses, pulse duration is inversely related to spectral bandwidth. Specifically, the minimum possible pulsewidth is proportional to the Fourier transform of the spectral bandwidth. Pulses that approach this theoretical limit are usually referred to as transform-limited pulses. As a result, any device that causes spectral narrowing of an ultrafast pulse will necessarily lengthen the pulsewidth. Furthermore, once a pulse is lengthened in this manner, there is no linear mechanism for compressing it back to its original pulsewidth.

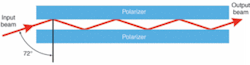

Group velocity dispersion also lengthens an ultrafast pulse. This effect arises because the speed of light in a material is a function of wavelength. Thus, when an ultrafast pulse transits a medium, longer wavelengths travel at speeds different from those at shorter wavelengths, causing the pulse to smear and increase in length (see Fig. 1). Pulse lengthening due to GVD can be compensated, however, by using a pulse compressor, which is an optical setup or component that possesses GVD opposite in sign and equal in magnitude to the GVD that caused the original pulse stretching.

Broadband-coated mirrors

The most important requirement for reflective thin films for use with femtosecond laser pulses is broad spectral bandwidth. These mirrors must also have a high laser-induced damage threshold and often must be transparent at the pump wavelength, if they are intracavity optics. For these reasons, dielectric stacks of titanium dioxide/silicon dioxide (TiO2/SiO2) are generally used because TiO2 is the highest-index transparent material available at 800 nm.

“Chirped” mirrors centered at 800 nm with controlled GVD are available, and can have bandwidths of up to 400 nm. But these mirrors are difficult to manufacture and use. Moreover, using multiple chirped mirrors can lead to a nonlinear dependence of GVD on wavelength—an effect that cannot be readily compensated by other optics. For this reason many commercial ultrafast-laser systems and the majority of beam-delivery systems use “single-stack” mirrors. Coating these mirrors, which have spectral bandwidths in excess of 200 nm, with optimized, nonquarterwave stacks can minimize their GVD.

To put this into a practical perspective, the majority of today’s ultrafast-laser systems are based on Ti:sapphire. Commercial Ti:sapphire lasers are available with pulsewidths routinely as short as 25 fs. At the peak of the Ti:sapphire gain curve (800 nm), the relationship between pulsewidth and spectral bandwidth for a 25-fs pulse dictates that these high-reflectivity mirrors have a bandwidth of at least 40 nm, assuming that the spectral shape of the pulse is Gaussian. Thus, the 200- to 230-nm bandwidth obtainable with TiO2/SiO2 mirrors allows for 25-fs pulses and significant wavelength tunability.

Finally, one way that manufacturers maximize the bandwidth of these single-stack mirrors is by using energetic coating techniques instead of conventional evaporation. Energetic processes increase the index of the TiO2 layers toward the bulk value. Increasing the index difference between the coating materials increases the spectral bandwidth.

All-reflective polarizers

Using broadband reflective optics instead of transmissive components, whenever possible, minimizes GVD. Many ultrafast applications require high-efficiency, high-extinction-ratio polarizers. These polarizers are required, for instance, in optical isolators used to prevent damaging back-reflections from an amplifier into the laser oscillator. Calcite polarizers are commonly used in conventional laser applications, but are problematic with ultrafast lasers because calcite exhibits a high degree of GVD. In contrast, a plate polarizer based on a reflective dielectric coating can be designed to deliver near-zero GVD, but such an optic will not deliver the extremely high extinction found with calcite.

The ultrafast-optical-science group at the Colorado School of Mines (Golden, CO) led by Jeff Squier, uses a novel polarizer system based on a pair of standard plate polarizers. Originally conceived by Barry Walker, now a professor of physics at the University of Delaware, this configuration does not have the GVD limitations of calcite. These rectangular (1 × 4 cm) polarizers are arranged in a parallel configuration. The beam is introduced at one end of this arrangement with an angle of incidence of 72° (see Fig. 2). The beam “bounces” between the pair of polarizers maintaining an angle of incidence of 72° at each reflection, while increasing its polarization at each reflection. Because these polarizer coatings have been designed for near-zero GVD, laser pulses are not stretched as they pass through the optic, even though they undergo multiple reflections.Depending on the application, the total extinction typically needs to be on the order of 104. This can be achieved with a design yielding six reflections. But even higher extinctions are possible by simply adjusting the number of bounces. (Each reflection will lose about 3% of the incident s-polarized energy and will increase the extinction ratio by about a factor of five).

How well does this type of polarizer assembly work in practice? When Squier’s team crossed two of these assemblies with a Faraday rotator or Pockels cell in between, they measured a typical extinction coefficient of 10-4—virtually the same value obtained with calcite prisms. Based on these measurements, the group has replaced the calcite throughout their ultrafast systems with these assemblies.

Ti:sapphire gain flattener

Many ultrafast applications require higher pulse energy than the nanojoule level of a typical Ti:sapphire oscillator. This need is met by use of an ultrafast amplifier—either a regenerative amplifier or a multipass amplifier. Here, a pulse picker allows an individual oscillator pulse to pass through a pulse stretcher before entering an amplifier containing a Ti:sapphire crystal that is pumped by a 532-nm laser. The pulse travels around the amplifier, gaining energy with every pass. After the pulse has gained enough energy, the pulse picker allows the amplified pulse to exit the amplifier and enter a compressor. (Pulse stretching and compression are needed to avoid damage to the internal amplifier optics caused by the high peak power). Different types of amplifiers allow either high (millijoule) pulse energies at repetition rates of a few kilohertz or less or higher repetition rates (up to 300 kHz) at more modest pulse energies.

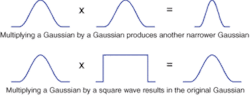

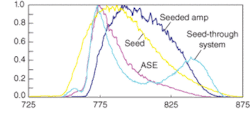

Unfortunately, even in highly optimized amplifier systems in which net GVD effects are close to zero, the amplified pulse will still have a longer transform limit than the original pulse because of a phenomenon known as gain narrowing. This effect arises because the spectral gain curve of Ti:sapphire is Gaussian (see Fig. 3). So, every time the pulse passes around an amplifier cavity, its shape is multiplied by the Gaussian shape. The end result is that the pulse acquires the spectral shape of (Gaussian)n, where n can be a large number. In simple terms, the pulse has higher energy in the middle of its spectrum and this part of the pulse undergoes high amplification. Conversely, at the edges of the bandwidth, the pulse has lower energy and is amplified by a lower gain factor. The pulse spectral width thus becomes successively narrowed, which increases pulse duration.A novel intracavity optic (gain flattener) recently developed to directly address this issue consists of a coated reflective window (beamsplitter) inserted in the cavity. The transmission curve of this filter is the mirror image of the Ti:sapphire gain curve. With this optic installed in an amplifier, the net gain as a function of wavelength for a single trip around the cavity becomes a square wave shape instead of a Gaussian (see Fig. 3). This eliminates gain narrowing because, no matter how many times the square wave is multiplied by itself, it never changes shape. Of course, successful implementation requires that the central transmission “dip” is carefully tailored in shape and that the transmission in the “wings” (700 to 750 nm and 850 to 900 nm) is high. Also, because this is an intracavity amplifier optic, the coating design, deposition method, and choice of coating materials have to be optimized to produce a high damage threshold filter.

This gain flattener has been extensively beta tested in the Squier and Durfee laboratory at The Colorado School of Mines. Spectral bandwidth was preserved during amplification enabling a final system pulsewidth of 20 fs (see Fig. 4). The researchers also demonstrated that the optic can be optimized for use at different amplifier wavelengths by changing the tilt angle of the gain flattener, which shifts the wavelength of the center dip. In addition, the optic can be used in regenerative and multipass amplifiers—amplifiers with quite different single-pass gain levels—because the magnitude of the “dip” can be adjusted simply by changing the axis (s versus p) that the optic is tilted about.New applications and simplified laser technology have broadened the market for ultrafast pulses. Critical to the successful construction and implementation of these lasers are robust optical components that preserve ultrafast pulse properties. Producing these components on a volume basis requires a thorough understanding of ultrafast laser technology, as well as rigorous thin-film design and production methodologies.

David Kemp is eastern regional sales manager and Rod Schuster is marketing manager at Alpine Research Optics, 3180 Sterling Circle, Boulder, CO 80301; email: [email protected]; www.arocorp.com.