DANIEL CHU and ROBERT POTENZA

The potential market for tunable lasers for optical networks is big, and if projections are correct, really big. Various estimates suggest the market may grow from a few million dollars in 2000 to perhaps a billion dollars by 2004. This potential is driving intense competition among a variety of tunable diode laser technologies, and several practical devices are now becoming a reality. Even as new tunable lasers hit the market, however, dense wavelength-division-multiplexing (DWDM) technology continues to evolve, opening up new applications and maintaining the pressure for improved performance.

Dense WDM network systems require one laser diode per channel as well as a backup source for each channel. Current DWDM systems carry up to 32 or 64 channels per fiber, and as channel spacing inevitably decreases from the current ITU standard of 100 GHz to the 50- and 25-GHz systems now under development, single fibers may eventually carry 200 to 300 discrete channels. This evolution of DWDM technology places stringent demands on diode sources in terms of bandwidth, linewidth, stability, and compactness. At the same time, these demands are making versatile tunable lasers an even more important and critical aspect of the network.

Although "sparing" (using a single tunable laser to provide backup for multiple fixed-wavelength source lasers) is probably their first application, tunable lasers ultimately may act as primary sources, allowing remote, real-time, command-driven network reconfiguration. Future developments also might enable networks such as Stanford University's Hybrid Optical Ring Network (HORNET) project, which would use fast tunable lasers and wavelength routing to deliver individual data packets based on the signal wavelength. Such developments may simplify system architecture by minimizing switching requirements and optimizing bandwidth allocation.

Tunable lasers, regardless of their specific architecture, contain three basic elements: a source diode with an active gain section and resonant cavity; a tuning mechanism for varying and selecting wavelength; and a means of stabilizing the output wavelength. Source diodes generally are a variation of the Fabry-Perot device, with the notable exception of vertical-cavity surface-emitting lasers (VCSELs). Tuning mechanisms can be temperature-, current-, or mechanically controlled, including microelectromechanical systems (MEMs). Wavelength stabilization is provided by some type of wavelength locker or etalon operating in a feedback control loop. There are three basic approaches, and numerous variations, that are being developed.

Distributed Bragg reflectors

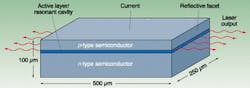

Conventional approaches to tunable diode lasers are based on distributed Bragg reflectors (DBRs) and the related distributed-feedback lasers (DFBs), which use an active Fabry-Perot gain section with an added diffraction grating. Devices from Agility (Santa Barbara, CA) and Altitun (Groton, MA; now part of ADC) are examples. A typical Fabry-Perot diode is a multiple epitaxial-layer semiconductor chip containing the active layer (or layers) and some type of internal waveguide structure. The resonant cavity is formed within the waveguide by controlling the reflectivity of the cleaved reflecting facets at either end (see Fig. 1). These diodes are typically about 250 µm wide by 500 µm long by 100 µm thick, with a correspondingly tiny resonant cavity. In practice, Fabry-Perot diodes generate several closely spaced wavelengths over a few nanometers and the output is very sensitive to slight changes in temperature and input current. With wavelengths of interest spaced 0.8 nm apart (or less), the Fabry-Perot diode by itself requires refinements to provide the control necessary for optical networks. Both DFB and DBR devices add a diffraction grating to a Fabry-Perot diode to provide that control.

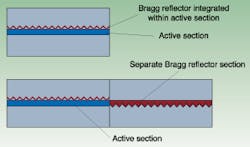

The diffraction grating (often referred to as a Bragg grating or Bragg reflector) provides feedback to the optical signal oscillation and acts to select a single mode of oscillation, or wavelength, based on the pitch of the grating. In a DFB laser, the diffraction grating is integrated into the active section of the diode, while in a DBR the grating is contained in a separate section coupled with the active section (see Fig. 2).The wavelength of a basic DFB or DBR laser is tuned by altering the refractive index of the cavity semiconductor material, which changes the speed of the photons as they travel between reflecting surfaces. The refractive index can be varied either by temperature control or by controlling the electrical current passing through. Distributed feedback devices offer good power output, on the order of 10 to 20 mW, but their tuning range is limited to 5 to 10 nm.

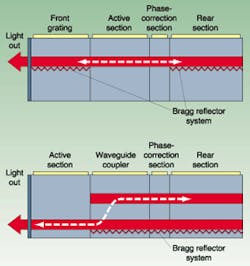

Several variations of DBR lasers have been developed to improve their basic performance and overcome their limitations. These include sampled-grating distributed Bragg reflectors (SG-DBR), in which a second diffraction grating is added to the gain section, and the gratings are situated at opposite ends of the cavity (see Fig. 3). Each grating is designed to have a slightly different pitch; each generates a comb-like series of wavelengths, offset from one another. The SG-DBR is tuned by varying the current to the grating cavities, which varies the refractive index and causes the combs to move across one another (a phenomenon known as the Vernier effect). The SG-DBR is designed so that for each tuning current only one set of wavelengths coincide and reinforce, thus producing the output wavelength.Sampled-grating DBRs offer a considerably wider tuning range, exceeding 40 nm, although they are generally limited to lower-power outputs—on the order of 2 mW. Higher powers can be achieved by incorporating an additional amplifier section with the chip, although this increases the cost and can compromise reliability. Switching speeds can be 10 ms with servo electronics.

Another version of the DBR is the grating-assisted codirectional coupler with sampled reflector (GCSR), which contains four sections (gain, Bragg reflector, coupling, and phase-correction) and is tuned using three currents. The current-controlled waveguide coupler acts as a coarse tuner to deliver a narrow range of wavelengths from the Bragg reflector—current-controlled to provide a level of selection—to the phase-correction section (also current-controlled), which acts as a fine-tuning section.

The GCSRs operate over a wide tuning range—on the order of 40 nm—but have more complicated electronic controls that limit switching speed, even though the semiconductor can switch in the nanosecond range. Like most other multisection diode lasers, power output is sacrificed and is low at 2 mW. Power output can be increased at the expense of tuning range by eliminating the coarse-tuning section.

External-cavity lasers

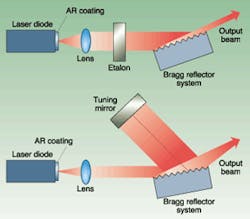

Other devices use a resonant cavity external to the active semiconductor section, which is typically a simple Fabry-Perot diode. New Focus (Santa Clara, CA) devices are based on this arrangement. A relatively large cavity containing a mechanically tunable (as opposed to current- or temperature-controlled) mirror/diffraction-grating configuration provides tuning. External-cavity lasers are generally based on either a Littrow cavity or Littman-Metcalf cavity design. In both designs, one facet of the diode is antireflection (AR)-coated and the laser output is directed through a collimating lens to the cavity on one side of the diode.

The Littrow cavity is the simpler of the two designs, and uses a diffraction grating that, by diffracting the beam back on itself toward the active section, also acts as one mirror of the cavity (see Fig. 4). Tuning is performed by mechanically rotating the grating, which changes its effective pitch. The Littman-Metcalf design uses both diffraction grating and mirror; the diffraction grating diffracts the light to the mirror, reflecting the beam back to the grating and the active section. Rotating the mirror varies the effective cavity length and tunes the laser.Both designs require projecting the beams from a grating over a distance, which makes the systems bulky. External cavity lasers offer substantially better performance in terms of higher output power, wider tuning range, and narrow linewidth, but until recently have been too large, mechanically sensitive, and expensive to find practical application in optical networks.

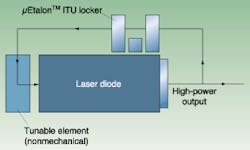

Compact external-cavity lasers are a recent development by Blue Sky Research. These devices offer the advantages of conventional external cavities in a configuration readily adaptable to optical networking applications. These lasers are based on a conventional Fabry-Perot diode, but with a compact external cavity containing a nonmechanical, nongrating, electro-optical tuning element (see Fig. 5). This approach significantly reduces the system size, allowing it to fit a standard butterfly package. It provides significant advantages over traditional external-cavity lasers by solving the tuning speed and size problems. Furthermore, the simple Fabry-Perot diode allows the costs to be reduced, so that they are comparable to DBR designs but with significantly improved performance. Also, the system's all-electronic, low-voltage, low-current tuning mechanism has a simpler control scheme compared with multiple-section DBR lasers. The overall tuning speed is thus further improved.The compact external-cavity laser offers high output power, up to 20 mW, over a wide wavelength range of 30 to 40 nm, which is comparable with larger and more expensive conventional external-cavity lasers. Switching speeds are potentially faster than 1 ms, and the nonmechanical tuning device is more reliable, as well as being compact and inexpensive.

VCSELs

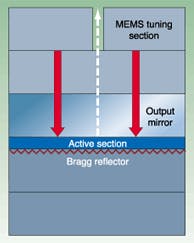

Vertical-cavity surface-emitting lasers are fundamentally different from Fabry-Perot and related lasers in that the resonant cavity is perpendicular to the semiconductor layers rather than transverse. Coretek (Wilmington, MA; now part of Nortel), for example, produces this type of system. Mirrors forming the cavity are located above and below the active section, and comprise alternating layers of semiconductor material with different refractive indexes to form Bragg reflectors (see Fig. 6). Tunable VCSELs are made using MEMS technology to incorporate a movable top mirror, allowing the cavity length to be varied to change the output wavelength.Vertical-cavity lasers are potentially tunable over a wide range, on the order of 40 nm, though MEMS switching is generally slow—on the order of milliseconds. Power output is usually only a few milliwatts, although current work with larger cavities and emitting apertures promises to increase power ratings. Finally, due to manufacturing and material constraints, VCSELs have not been practical at the optical telecom wavelengths of 1300 or 1550 nm, although that also is under development.

Tunable lasers continue to evolve, and advances in design address the current challenges in performance and manufacturing. It is unlikely, though, that a single technology will dominate. For example, millisecond or even second switching speeds may be acceptable for sparing applications, while packet-switching architectures may require higher speeds. Accordingly, as DWDM networks mature, variations of the underlying architecture and applications will remain to accommodate a variety of tunable lasers differentiated by cost and performance.

Daniel Chu is director of telecommunications and Robert Potenza is senior vice president of marketing and sales at Blue Sky Research, 1537 Centre Pointe Dr., Milpitas, CA 95035. Contact Bob Potenza at [email protected].