'Subambient' optical coating lowers summertime roof temperature to 11 degrees C below that of a white roof

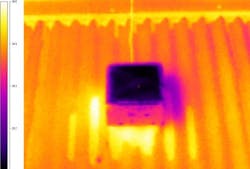

Angus Gentle and Geoff Smith of the University of Technology Sydney (Sydney, Australia) have created a coated polymer stack that, when tested as a roof surface, stayed 11°C cooler than a nearby commercial white cool roof.1

The stack consists of a combination of polyesters on a silver thin-film layer. The result is a solar reflectance of almost 100%, along with high emittance at thermal infrared wavelengths from 7.9 to 13 μm.

"We demonstrate for the first time how to make a roof colder than the air temperature around it, even under the most intense summer conditions," says Smith.

The polymer materials used for the demonstration were available commercially and potentially suited to use on basic roofing, he adds. "Cool roofing reduces the severity of the urban heat island problem in towns and cities and helps eliminate peak power demand problems from the operation of many air conditioners," he says.

Data was collected for an unprotected new surface and one aged over several days in a polluted outdoor summer environment for assessment of the impact of the build-up of dust and grime.

Smith says that the surface maintained its high performance in all conditions. "Extensive dew formation is inevitable for a super cool roof and dew drops precipitate dirt," he explains. "This roof site being 25 m above a busy city transit road was a stern test. Results show that excellent thermal performance can be maintained."

The work has been supported by an Australian Research Council Discovery Project grant.

Source: http://newsroom.uts.edu.au/news/2015/05/super-cool-roof-solution-being-hot-city

REFERENCE:

1. Angus R. Gentle andGeoff B. Smith, Advanced Science (2015); doi: 10.1002/advs.201500119

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.