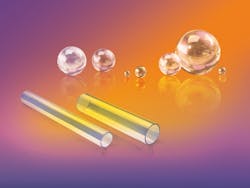

Low-pressure chemical vapor deposition (LPCVD) coatings use a proprietary (~500°C) high-temperature process to create conformal, seamless coatings on substrates including glass, ceramics, and metals. They feature laser damage thresholds (LDT) up to 25 MW/cm2. Ball lenses, micro-optics, and other complex shapes may be coated.

Deposition Sciences

Santa Rosa, CA

www.depsci.com

Sponsored Recommendations

Sponsored Recommendations

March 31, 2025

March 31, 2025

March 31, 2025

March 31, 2025

Voice your opinion!

Voice your opinion!