Optical Surfaces to supply diagnostic optics for fusion research project

Optical components and instruments manufacturer Optical Surfaces (Surrey, England) received a sizeable order from the Culham Centre for Fusion Energy (CCFE; Oxfordshire, England) to manufacture the relay imaging reflective optics that will form part of two critical viewing diagnostic assemblies for the Joint European Torus (JET) when operating with a deuterium-tritium fuel mixture. The project is funded under the framework of EUROfusion (https://www.euro-fusion.org/).

RELATED ARTICLE: Spectroscopic studies on ITER fusion reactor walls use Andor ICCD camera

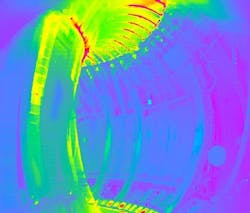

Comprising a series of large diameter (up to 500 mm) ultrasmooth flat and spherical mirrors, some of which will have a very long radius of curvature, the relay imaging reflective optics will allow CCFE to monitor a number of physical and operational parameters within the JET fusion vessel with remote cameras from behind the 3 m thick concrete shield wall. Knowledge of these parameters will ensure safe and smooth operation during JET’s planned campaign of fusion experiments using a deuterium-tritium fuel mixture. The relay imaging will be performed mainly with reflective optics because these are resilient to the hostile conditions that high energy neutrons and radiation present to them inside the Torus Hall.

CCFE is the UK's national laboratory for fusion research. CCFE is owned and operated by the United Kingdom Atomic Energy Authority (UKAEA). CCFE hosts JET--the world’s largest magnetic fusion experiment--on behalf of its European partners. The JET facilities are collectively used by European fusion scientists, coordinated under EUROfusion.

Tim May-Smith, diagnostics support physicist/engineer at CCFE said, "Selecting a supplier to manufacture the component optics was a very important decision because of the critical role that the relay cameras will play in the safe operation of JET. Optical Surfaces Ltd. was our selected supplier because of their experience and knowledge in the area of large optics, precision manufacturing expertise and value-for-money offered."

Optical Surfaces has been producing optical components and systems for more than 50 years and says it is now accepted as one of the world’s leading manufacturers of large high-precision optics and optical systems for fusion research. The company's ISO 9001-2008 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions, testing, particularly with long path lengths, becomes quantifiable and reliable.

SOURCE: Optical Surfaces; http://www.optisurf.com/index.php/relay-reflective-optics-for-joint-european-torus/

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.