Optical Surfaces supplies wide-field imaging lenses for Aristarchos Telescope

Optical Surfaces (Surrey, England) has supplied the National Observatory of Athens (http://www.astro.noa.gr) a series of high-precision lenses designed for a new state-of-the-art wide-field imager that will extend the capabilities of its 2.3 m Aristarchos Telescope.

The Aristarchos Wide-Field Camera (AWFC) is a new wide-field imager that will be used on the 2.3m Aristarchos telescope at the Helmos Observatory in Greece. It has a 26 x 26 arcmin field of view on the sky with a resolution of better than 1 arcsecond per pixel. The AWFC will be used for SDSS imaging and calculation of precise photometric redshifts of objects (such as supermassive black holes in galactic nuclei) in sky fields covered by the ESA/XMM satellite and high-resolution narrowband imaging of large filamentary structures, including supernova remnants and planetary nebulae that are the end points in the life of stars.

RELATED ARTICLE: Ground-based sky survey telescopes challenge large FPA technology

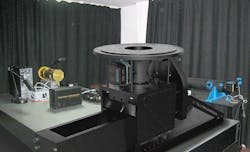

For the latter, the AWFC will provide unique information about their structure and morphology which will help significantly to study their kinematics and dynamics together with subsequent spectroscopic observations. The wide-field imager has been manufactured and is in its testing phase in the optical lab. Commissioning of the AWFC on the 2.3m Aristarchos telescope and first light is expected in 2017.

The National Observatory of Athens (NOA) selected Optical Surfaces to manufacture and supply the 160 mm diameter lens and collimator lens assembly comprising a cemented doublet, a meniscus lens, and a biconvex lens to perform well over a wide range of wavelengths, in order to maintain the high performance and achromatic nature of the reflective optics of the Aristarchos telescope but over a much wider field of view.

Panayotis Boumis, a senior researcher within the NOA, said, "Throughout the project--Optical Surfaces provided us with a wealth of valued technical input demonstrating their extensive experience and knowledge in the area of designing high precision optics and lens assemblies for telescopes."

Optical Surfaces has been producing optical components and systems for more than 50 years and says it is now accepted as one of the world's leading manufacturers of high-precision optics for ground-based and space-based telescope systems. The company’s ISO 9001-2008 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent. With such stable conditions, testing, particularly with long path lengths, becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.

SOURCE: Optical Surfaces; http://www.optisurf.com/index.php/high-performance-lenses-for-state-of-the-art-wide-field-imager/

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.