An international research team led by Natalia Dubrovinskaia and Leonid Dubrovinsky of the University of Bayreuth (Bayreuth, Germany) has created a diamond-anvil-based device that for the first time has reached a static pressure of 1 terapascal, which is three times higher than the pressure at the center of the Earth.1

Diamond anvils enable high-pressure experiments for physics, chemistry, materials science, and industry; because they are optically transparent, they allow spectroscopic examination of the test specimen at optical and x-ray wavelengths, as well as laser heating of the sample.

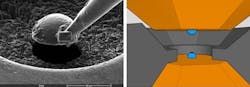

The extreme pressure was obtained with the help of two 10 to 15 μm diameter hemispheres of nanocrystalline diamond (made by cutting a nanocrystalline diamond sphere in half with an ion beam). The nanodiamond-based material has a compressive strength higher than monocrystalline diamond due to the unique nanocrystalline structure. The two hemispheres were installed in a conventional double-sided diamond anvil cell, creating much smaller areas of contact and thus much higher pressures. X-ray diffraction measurements of the specimen (a mixture of gold and paraffin wax) confirmed the terapascal pressure.

The study was published by the Bavarian Geoinstitut (BGI) and the Laboratory of Crystallography of the University of Bayreuth. Numerous other research partners were also involved: the Center for Advanced Radiation Sources at the University of Chicago, the European Synchrotron Radiation Facility in Grenoble, the University of Antwerp, the Karlsruhe Institute of technology (KIT), and the Immanuel Kant Baltic Federal University in Kaliningrad. Crucial experiments were carried out by the Bayreuth scientists at Argonne National Laboratory (Chicago, IL).

Source: https://www.uni-bayreuth.de/de/universitaet/presse/pressemitteilungen/2016/116-rekord-hochdruckforschung/index.html

REFERENCE:

1. Natalia Dubrovinskaia et al., Science Advances (2016); doi: 10.1126/sciadv.1600341

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.