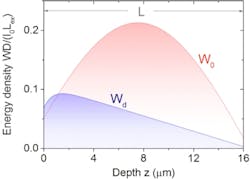

When light enters a highly scattering medium, its intensity within the medium normally falls exponentially as a function of the distance into the medium. However, researchers at the University of Twente (Enschede, Netherlands) can now couple light into a scattering medium such that the light peaks farther within the medium; they measure the peak's shape and position via the response of fluorescent particles scattered throughout the medium.

The researchers bring light into the medium using a spatial light modulator (SLM), which shapes the wavefront phase such that the light couples to just one of the scattering medium's "diffusion eigensolutions." (In conventional scattering, there are many resulting eigensolutions that average together to produce the ordinary exponential decay.)

Setup

In the experiment, the scattering medium is a slab of zinc oxide nanoparticles mixed with dye-doped polystyrene nanospheres, with a slab thickness of from 2 to 22 μm. A laser made by Cobolt (Solna, Sweden) emitting at 561 nm excites the spheres to emit at 612 nm.

The laser light is stabilized by coupling it into and out of a single-mode fiber; the phase-only liquid-crystal SLM, which is made by HoloEye Photonics (Berlin, Germany) then shapes the phase front before the light enters the scattering medium. The light exiting the medium is split by a dichroic beamsplitter so that the 561 nm light goes to a CCD camera, while the 612 nm light goes to an electron multiplying CCD (EMCCD) made by Andor (Belfast, Ireland).

The EMCCD (aided by calculations) measured the fluorescent power enhancement as a function of sample thickness. Measurements were taken for both the optimized and a nonoptimized wavefront.The observed enhancement increased with sample thickness. The results showed that stored light power within a 22.8-μm-thick scatterer was boosted by a factor of 4.6 by the wavefront-shaping technique.

Practical benefits for devices, bioscience

Becuase the University of Twente technique boosts stored energy within a scattering medium, it could help raise efficiencies of solar cells in the near IR; in addition, it could enhance light conversion within the phosphors of white-light LEDs, making them more efficient.

In the bio-optics field, the technique could allow more uniform excitation of fluorescent probes in biological tissues.

Source: https://www.utwente.nl/en/news/!/2016/4/184748/manipulating-light-inside-an-opaque-layer

REFERENCE:

1. Oluwafemi S. Ojambati et al., New Journal of Physics (2016); http://stacks.iop.org/1367-2630/18/i=4/a=043032

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.