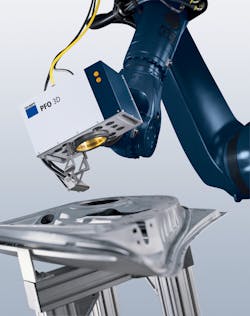

PFO 3D programmable focusing optics for scanner welding, cutting, and drilling increase the maximum work area of the laser to 20.8 × 30.7 in. in elliptical form, with a Z stroke of up to ±18.7 in. Maximum laser power has been increased to 8 kW. A robot-mounted PFO can be controlled on the fly.

TRUMPF

Farmington, CT

www.us.trumpf.com

More Products

-----

PRESS RELEASE

Power and precision: TRUMPF Programmable Focusing Optics

FARMINGTON, Conn. - TRUMPF has introduced the latest generation of its Programmable Focusing Optics, the PFO 3D, for scanner welding, cutting and drilling. The new PFO 3D features a larger work area, higher maximum laser power, and enhanced electronics for increased accuracy.

With the new generation PFO 3D, the maximum work area of the laser has been increased to 20.8 inches x 30.7 inches in elliptical form with a Z stroke of up to ± 18.7 inches. The maximum laser power has also been increased to up to 8 kW. To minimize repositioning time and maximize performance in larger applications, a robot mounted PFO can be controlled to process "on the fly" through real time synchronization of the scanner axes and robot axes.

Innovative advancements to the PFO 3D electronics ensure increased accuracy at the work piece. With the CalibrationLine function, for example, the exact position of the focal point and the power of the laser beam can be determined. The Mirror Stabilization Program (MSP) corrects mirror positions measured in offset and gain, independent of temperature and humidity. The addition of the "wobble" feature improves material processing capabilities in bridging gaps, battery welding and creating repeating pattern for larger contact area with a small focus spot. These changes significantly improve repeatability and enable precise processing results in applications with extremely defined requirements.

###

TRUMPF is one of the world's largest producers of fabricating machinery and a world market leader in lasers used for industrial production technology. Additional company information is available at: www.us.trumpf.com

-----

Follow us on Twitter

Subscribe now to Laser Focus World magazine; it's free!