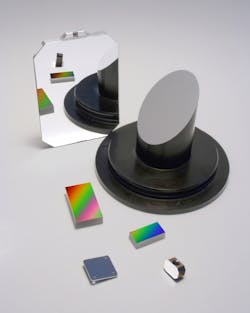

Optical replication process from OPCO Laboratories produces ruled and holographic diffraction gratings

A proprietary Replication Process transfers the profile of a precision optical surface from a master, creating an exact duplicate on a variety of substrates, including glass, silicon carbide, ceramic, and metals. It can produce both ruled and holographic diffraction gratings, reflective and transmission holographic optical elements, and dual-wavelength gratings, as well as plano and conic sections.

OPCO Laboratories

Fitchburg, MA

[email protected]

-----

PRESS RELEASE

OPTICAL REPLICATION PROVIDES COST-EFFECTIVE VOLUME PRODUCTION OF COMPLEX OPTICAL SURFACES

FITCHBURG, MA — The OPCO proprietary Replication Process reproduces complex optics with unsurpassed surface accuracy, quality, and repeatability.

For production of high-performance optics at volume quantities, the OPCO Replication Process cost-effectively transfers the profile of a precision optical surface from a master, creating an exact duplicate on a variety of substrates. The benefits of the process are replicated optics that are identical to the master, less expensive, and in many cases lighter.

The Replication Process is used to produce a wide range of both ruled and holographic diffraction gratings, reflective and transmission holographic optical elements, and dual wavelength gratings, as well as plano and conic sections. Substrate materials include glass, silicon carbide, ceramic, and metals such as beryllium, aluminum, titanium, stainless steel, and others. Additional mounting holes and other features such as tabs can even be incorporated into a metal replica.

Diffraction gratings are produced in sizes up to 110mm x 110mm with groove densities from 40 g/mm to 3600 g/mm, with available wavelengths from the deep UV to the far IR.

For applications in medicine, aerospace, national defense, motion-picture production, and other fields, OPCO manufactures the original master to be replicated (or will replicate from a supplied master). OPCO also provides the ability to produce optics with custom coatings to exactly match customer specifications.

The OPCO Replication Process provides absolute performance matching from the first to the last replicated item. Surface accuracy and radii are certified to customer specifications using a ZYGO™ interferometric measuring system, profilometer, or other measuring system depending on the optic configuration.

Since 1976 OPCO has been a leading manufacturer of custom precision optics for the scientific, commercial, and defense industries. From designing and prototyping to high-volume production, OPCO provides comprehensive, cost-effective optical solutions, including lenses, prisms, beamsplitters, mirrors, windows, filters, domes, replicated optics, and diffraction gratings.

For more information on the proprietary OPCO Replication Process, contact Bob Moody, OPCO Laboratory, Inc., 704 River Street, Fitchburg, MA 01420, TEL: (978) 345-2522, FAX: (978) 345-5515, E-mail: [email protected], Web: www.opcolab.com.

-----

Subscribe now to Laser Focus World magazine; it's free!