3D interferometric microscopy reveals medical implant wear mechanisms

Bruker Corp. (Santa Barbara, CA) says that 3D microscopy based on white-light interferometry can provide high-speed measurement with higher lateral resolution and better vertical measurement accuracy than competing technologies, including 2D stylus metrology and confocal microscopy. Furthermore, 3D optical microscopy has a noncontact advantage: Stylus systems can induce mechanical filtering due to the contact-tip radius and can also damage the surface under test. In addition to surface-metrology and inspection applications in the automotive, aerospace, solar, and semiconductor markets, these systems are also suited to surface characterization of medical devices such as hip implants.

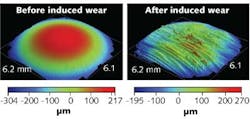

Using dual-LED illumination, a wavelength-filtering system that optimizes light levels for both smooth and rough surface textures, and an ultralow-noise CCD camera for subnanometer-resolution imaging, the ContourGT and NPFLEX 3D optical microscopes can examine the behavior of materials over a range of time scales as they are worn via cutting or grinding operations, or where material wear is produced due to constant contact with other components. These particular wear mechanisms are prominent in hip implants where there is contact by design. The system can also quantify material removal due to friction that can result in debris causing inflammation of the tissue surrounding the implant. The implants can be analyzed pre- and post-wear to automatically compute the volume-displacement and material-removal parameters, providing quantitative analysis of surface-wear scar depths and texture with a 5X better accuracy than gravimetric computations. Contact Matt Novak at [email protected].

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.