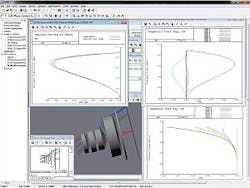

CODE V 10.3 includes enhancements to the optical design and analysis software. New features include support for Q-type aspheric surfaces, enhanced surface conversion capabilities, a new algorithm for automatic determination of optimum locations for aspheric surfaces in the lens system, and built-in aspheric constraints to control slope and sag during design optimization.

Synopsys

Mountain View, CA

www.synopsys.com

-----

PRESS RELEASE

Synopsys’ CODE V Enhances Aspheric Lens System Design

Available from Synopsys as part of its acquisition of Optical Research Associates, CODE V Version 10.3 is now generally available

Highlights:

- Support for Q-type aspheric surfaces that deliver superior cost control and manufacturing benefits

- Enhanced surface conversion capabilities

- Efficient new algorithm for automatic determination of optimum locations for aspheric surfaces in the lens system

- Built-in aspheric constraints to control slope and sag during design optimization

MOUNTAIN VIEW, Calif., March 15, 2011―Synopsys, Inc. (Nasdaq: SNPS), a world leader in software and IP for semiconductor design, verification and manufacturing, today announced the availability of enhancements to its CODE V® optical design and analysis software. CODE V 10.3 delivers new design and analysis capabilities that enable optical designers to more easily take advantage of the unique image quality and cost benefits that aspheres offer.

Aspheric surface shapes are used to help reduce or eliminate imperfect or blurred images in optical systems. While surfaces with spherical shapes are easier to make, many more spherical surfaces are generally needed to reduce image blurring compared to aspheric surfaces. This means that an aspheric lens can be used to replace multiple spherical lenses, thereby creating a device that is smaller, lighter and potentially less expensive.

“Developments in optical fabrication and metrology are making the use of aspheres in optical design more cost effective,” said George Bayz, vice president and general manager of the Optical Solutions Group at Synopsys. “A key to achieving these cost savings is ensuring during initial design phases that the aspheres can be manufactured as designed. CODE V 10.3 delivers capabilities that help designers add aspheres to a system with the confidence that their designs will be both manufacturable and within budget.”

“The new aspheric design tools in CODE V helped me simplify an existing design while maintaining the required image quality,” said Jim Cornell, senior optical designer, Corning Advanced Optics. “In particular, the program’s fast, efficient surface conversion and optimization capabilities resulted in an improved system with fewer aspheric elements.”

Support for Q-type Aspheric Surfaces

CODE V 10.3 adds support for new native aspheric surfaces based on mathematical formulations recently published by Dr. G.W. Forbes of QED Technologies. These Q-type aspheric surfaces offer many advantages over traditional polynomial-based aspheres for lens design optimization and tolerancing. For example, the Q-type surfaces can be more easily constrained during optimization to improve manufacturability and reduce cost. In addition, CODE V’s fast wavefront differential tolerancing feature supports tolerancing on Q-type polynomial coefficients, which is useful for evaluating system performance and manufacturability.

Enhanced Surface Conversion Capabilities

CODE V’s enhanced surface conversion capabilities make it easy to switch back and forth between the Q-type formulations and traditional aspheric surface representations. This allows designers to harness the power of the new formulations while maintaining compatibility with established fabrication processes.

Asphere Expert Tool

CODE V’s Asphere Expert tool saves users time and effort by automatically finding optimal asphere locations in the lens system. The tool uses a unique, highly efficient algorithm that takes into account both aspheric slope departure limits and weighted constraints when computing recommended aspheric surface locations. Users have the option to convert selected surfaces to aspheres and optimize the resulting system for best final performance.

Built-in Aspheric Constraints for Design Optimization

New built-in optimization constraints in CODE V allow users to directly control the sag or slope variations of Q-type aspheres to maintain manufacturability of the lens system. For example, these constraints give users the ability to prevent the production of designs where the sag of the aspheric parts is too large for interferometric testing, and to ensure that designs do not require removal of an excessive amount of material during polishing phases. In addition, a new macro function allows aspheric surfaces to be evaluated and optimized for testability using ZYGO’s VeriFire Asphere interferometer metrology system.

Availability

The CODE V 10.3 release is available now and can be obtained by emailing [email protected].

About CODE V

Formerly an Optical Research Associates (ORA®) product, CODE V is an optical engineering and design software solution that supports the optimization, analysis and tolerancing of image-forming optical systems and free-space photonic devices. ORA is now part of Synopsys, Inc. For more information visit http://www.synopsys.com/Tools/OpticalDesign.

About Synopsys

Synopsys, Inc. (Nasdaq:SNPS) is a world leader in electronic design automation (EDA), supplying the global electronics market with the software, intellectual property (IP) and services used in semiconductor design, verification and manufacturing. Synopsys’ comprehensive, integrated portfolio of implementation, verification, IP, manufacturing and field-programmable gate array (FPGA) solutions helps address the key challenges designers and manufacturers face today, such as power and yield management, system-to-silicon verification and time-to-results. These technology-leading solutions help give Synopsys customers a competitive edge in bringing the best products to market quickly while reducing costs and schedule risk. Synopsys is headquartered in Mountain View, California, and has approximately 70 offices located throughout North America, Europe, Japan, Asia and India. Visit Synopsys online at http://www.synopsys.com/.

-----

Posted by Lee Mather

Follow OptoIQ on your iPhone; download the free app here.

Subscribe now to Laser Focus World magazine; it's free!