Corning introduces Gorilla Glass 4, next generation of chemically strengthened glass for displays, devices

Corning (NYSE:GLW; Corning, NY) has unveiled its newest form of chemically strengthened glass, Gorilla Glass 4, intended for smartphones, tablets, and other devices. Corning says the glass is "up to two times tougher than any competitive cover-glass design now in the market."

After examining hundreds of broken devices, scientists at Corning determined that damage caused by sharp contact accounted for more than 70% of field failures. They then developed new drop-test methods that simulated real-world break events. The scientists used the new methods to drop devices face down from a height of 1 m such that the cover glass directly contacted a rough surface (see video).

They determined that Gorilla Glass 4 survived up to 80% of the time while soda-lime glass, as deployed in today’s commercial devices, broke nearly 100% of the time.

Gorilla Glass 4 is manufactured using Corning’s fusion draw process. To strengthen the glass, it is chemically treated to produce a compressive stress of at least 850 MPa in a 90 µm layer at the upper and lower surface of the glass, leaving the inner, protected portion under a smaller amount of tensile stress.

No propagation of flaws

The process leaves the glass with a core refractive index of 1.49 and a compression-layer refractive index of 1.51, and also hardens it a bit, from a Vickers hardness (200 g load) for unstrengthened glass of 489 kgf/mm2 to a hardness for strengthened glass of 596 kgf/mm2. However, the primary reason that Gorilla Glass is not prone to fracture when dropped is that the surface is always in compression; as a result, if a small flaw is formed, it does not propagate through the glass to form a crack.

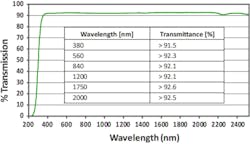

The glass is available in thickness of 0.4 to 2.0 mm and transmits well through the visible and near-infrared (see figure at top). Product sampling and shipment for Gorilla Glass 4 are already underway.

Source: http://www.corning.com/news_center/news_releases/2014/2014112001.aspx

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.