Diamond photonic-crystal cavities allow precise positioning of nitrogen-vacancy emitters

The nitrogen vacancy (NV) center, which is a nitrogen atom and a vacant site that together replace two adjacent carbon atoms in a diamond crystal, can store quantum digital information at room temperature in the form of electron spin, which can then be read out by the light it emits when illuminated by a laser, and used in a quantum computer. However, the weak signal is hard to identify, extract, and transmit unless it is intensified.

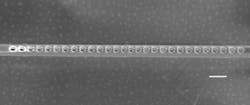

Researchers at Harvard University (Cambridge, MA); the University of California, Santa Barbara; the University of Chicago (Chicago, IL); and the University of Technology Sydney (Ultimo, Australia), have figured out how to do just that, creating a diamond photonic-crystal nanobeam cavity with a quality factor Q of up to 24,000 that enhances the relevant photon emission by about a factor of 30.1

"A photonic cavity that is properly matched to the NVs can substantially augment their capabilities," says Evelyn Hu, a researcher at Harvard whose group studies the optical and electronic behavior of nanoscale material structures.

NV centers whose signal is enhanced by photonic cavities could act as qubits, the fundamental units of quantum information in a quantum computer.

Delta doping

Hu and her colleagues ultimately aim to make sure the strongest portion of the resonant field will always coincide with the NV center; they can do this by knowing the exact position of the NV centers.

The team took an important first step toward this goal by controlling the depth of the diamond defects via a technique called delta doping. "Integrating a plane of spins into these structures enables us to engineer the spin-photon interaction and exploit quantum effects for future technologies," says David Awschalom, a researcher at the University of Chicago whose group grows and characterizes these systems. The technique confines the possible location of NV centers to a layer approximately 6 nm thick sandwiched inside a diamond membrane approximately 200 nm thick. The researchers then etched holes into the membrane to create the photonic cavities.

Using this method the researchers were able to increase the intensity of the light emitted by the NV centers by a factor of about 30 times.

The team is currently working on possible ways to achieve full 3D position control.

Source: http://www.aip.org/publishing/journal-highlights/qubit-candidate-shines-brighter

REFERENCE:

1. Jonathan C. Lee et al., Applied Physics Letters (2014); http://dx.doi.org/10.1063/1.4904909

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.