High-resolution 3D printed microscope is promising for medical diagnostics in developing countries

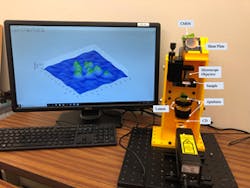

| A holographic digital microscope is made of 3D printed parts and commonly found optical components. The image on the screen shows 3D reconstructed results for a green algae sample. (Credit: Bahram Javidi, University of Connecticut) |

Researchers from the University of Connecticut (Storrs, CT) and the University of Memphis (Memphis, TN) have used 3D printing to make an inexpensive and portable high-resolution microscope that is small and robust enough to use in the field or at the bedside.1 The high-resolution 3D images provided by the instrument could potentially be used to detect diabetes, sickle cell disease, malaria and other diseases. The digital holographic microscope uses a structured illumination pattern to produce twice the resolution of conventional illumination.

In traditional digital holographic microscopy, a digital camera records a hologram produced from interference between a reference light wave and light coming from the sample. A computer then converts this hologram into a 3D image of the sample. Although this microscopy approach is useful for studying cells without any labels or dyes, it typically requires a complex optical setup and stable environment free of vibrations and temperature fluctuations that can introduce noise in the measurements. For this reason, digital holographic microscopes are generally only found in laboratories.

The researchers boosted the resolution of digital holographic microscopy beyond what is possible with uniform illumination by combining it with structured-illumination microscopy, a superresolution technique. They did this by generating a structured light pattern using a clear compact disc.

3D printed mechanical structure

"The entire system consists of 3D printed parts and commonly found optical components, making it inexpensive and easy to replicate," says research team leader Bahram Javidi from the University of Connecticut. "Alternative laser sources and image sensors would further reduce the cost, and we estimate a single unit could be reproduced for several hundred dollars. Mass production of the unit would also substantially reduce the cost. 3D printing the microscope allowed us to precisely and permanently align the optical components necessary to provide the resolution improvement while also making the system very compact."

The researchers evaluated the system performance by recording images of a resolution chart and then using an algorithm to reconstruct high-resolution images. This showed that the new microscopy system could resolve features as small as 0.775 μm, double the resolution of traditional systems. The light source was a 633 nm helium-neon laser; using a light source with shorter wavelengths would improve the resolution even more, say the researchers.

Additional experiments showed that the system was stable enough to analyze fluctuations in biological cells over time, which need to be measured on the scale of a few tens of nanometers. The researchers then demonstrated the applicability of the device for biological imaging by acquiring a high-resolution image of a green algae.

"Our design provides a highly stable system with high resolution," says Javidi. "This is very important for examining subcellular structures and dynamics, which can have remarkably small details and fluctuations."

Beyond a first prototype

The researchers say that the current system is ready for practical use. They plan to use it for biomedical applications such as cell identification and disease diagnosis and will continue their collaboration with their international partners to investigate disease identification in remote areas with limited health care access. They are also working to further enhance the resolution and signal-to-noise ratio of the system without increasing the device's cost.

Source: https://www.osa.org/en-us/about_osa/newsroom/news_releases/2019/new_3d_printed_microscope_promising_for_medical_di/

REFERENCE:

1. T. O’Connor et al., Optics Letters, 4, 9, 2326-2329 (2019); doi: https://doi.org/10.1364/OL.44.002326.