AMO and SUSS MicroTec collaborate in large-area UV-cured nanoimprinting

Aachen, Germany--AMO GmbH and SUSS MicroTec AG (Garching, Germany) are working on the development of applications for sub-50-nm substrate-conformal imprint lithography (SCIL) using UV-curing material.

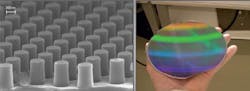

AMO has provided two key components for the development: the masters for large-area nanostructures, and the UV-curing nanoimprint material, called Amonil. The masters, with a size up to 6 in., are fabricated at AMO by laser-interference lithography and plasma etching in silicon. They have perfect binary periodic patterns with periods anywhere between 180 and 2500 nm. These holographic gratings are characterized by seamless patterns and a low defect density on a large area.

SUSS MicroTec's SCIL imprint method optimizes standard imprinting processes for full-field imprinting of wafers up to 6 in. in size. High-resolution nanoimprinting--previously limited to small wafer sizes--can now be successfully applied to large substrates. Large-area soft stamps with repeatable sub-50-nm printing capability do not cause any stamp deformation or damage, as no contact force is applied and soft, flexible material is used. When used with UV-curing materials, SCIL combines a high resolution with a high throughput. SCIL can be used with a large variety of well-known materials that are commonly used in UV nanoimprinting processes.

Hundreds of flexible stamps can be replicated from one master. With SCIL technology, the large-area stamp is brought into contact with the Amonil resist, which is then cured with UV light. The resist material was optimized by AMO for the implementation of quartz and soft PDMS stamps in conventional imprint processes. The imprint resist material has a standard thickness from 100 to 800 nm. Due to the unique sequential contacting and separation technology, a distortion-free replication of the stamp at high throughput is now possible using UV SCIL.

Applications include refractive and diffractive optical elements (as well as non-photonic uses such as patterned magnetic media, printed electronics, and RFIDs).

Subscribe now to Laser Focus World magazine; it’s free!

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.