Polymerized silicon nanosheets could compete with graphene

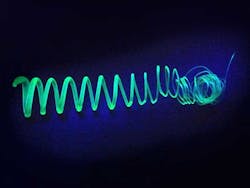

Researchers at the Technical University of Munich (TUM) have, for the first time ever, produced a composite material combining silicon nanosheets and a polymer that is both UV-resistant and easy to process, bringing the scientists closer to industrial applications like flexible displays and photosensors.1

RELATED ARTICLE: SUNY nanosheets could radically improve low-light imaging

Similar to carbon, silicon forms two dimensional networks that are only one atomic layer thick. Like graphene, for whose discovery Andre Geim and Konstantin Novoselov received the Nobel Prize in 2010, these layers possess extraordinary optoelectrical properties. Silicon nanosheets could thus find application in nanoelectronics, for example in flexible displays, field-effect transistors, and photodetectors. With its ability to store lithium ions, it is also under consideration as an anode material in rechargeable lithium batteries.

"Silicon nanosheets are particularly interesting because today's information technology builds on silicon and, unlike with graphene, the basic material does not need to be exchanged," explains Tobias Helbich from the WACKER Chair for Macromolecular Chemistry at TUM. "However, the nanosheets themselves are very delicate and quickly disintegrate when exposed to UV light, which has significantly limited their application thus far."

Now Helbich, in collaboration with professor Bernhard Rieger, Chair of Macromolecular Chemistry, has for the first time successfully embedded the silicon nanosheets into a polymer, protecting them from decay. At the same time, the nanosheets are protected against oxidation.

"What makes our nanocomposite special is that it combines the positive properties of both of its components," says Tobias Helbich. "The polymer matrix absorbs light in the UV domain, stabilizes the nanosheets and gives the material the properties of the polymer, while at the same time maintaining the remarkable optoelectronic properties of the nanosheets."

The first successful application of the nanocomposite constructed by Helbich was only recently presented in the context of the ATUMS Graduate Program (Alberta / TUM International Graduate School for Functional Hybrid Materials): Alina Lyuleeva and professor Paolo Lugli from the Institute of Nanoelectronics at TU Munich, in collaboration with Helbich and Rieger, succeeded in building a photodetector based on these silicon nanosheets. To this end, they mounted the polymer embedded silicon nanosheets onto a silicon dioxide surface coated with gold contacts. Because of its Lilliputian dimensions, this kind of nanoelectronic detector saves both space and energy.

REFERENCE

1. T. Helbich et al., Advanced Functional Materials 26, 37, 6711-6718 (2017).

SOURCE: Technical University of Munich; https://www.tum.de/en/about-tum/news/press-releases/detail/article/33796/

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.