Atomic layer deposition promises dramatic improvements in large telescope mirror coatings

A chance meeting between University of California, Santa Cruz materials scientist Nobuhiko Kobayashi and astronomer Joseph Miller, former director of UC Observatories (UCO, also Santa Cruz) at a wine party has led to a collaborative effort between Kobayashi and UC Santa Cruz astronomers Andrew Phillips and Michael Bolte to develop new protective optical coatings for large silver-based telescope mirrors by adapting a technique widely used in the microelectronics industry.

"It turns out that improving the performance of mirrors is all about thin-film materials, and that's what I do," says Kobayashi. "So then I got hooked."

Enabling silver rather than aluminum

Phillips notes that most astronomical telescope mirrors use aluminum for the reflective layer, despite the superior reflective properties of silver. "Silver is the most reflective material, but it is finicky to work with, and it tarnishes and corrodes easily," he says. "You need barrier layers on top that can keep anything from getting through to the silver without messing up the optical characteristics of the mirror."

The researchers are using atomic layer deposition (ALD), which builds a thin film of material one molecular layer at a time with excellent uniformity, thickness control, and conformity to the surface of the substrate. In a pilot study, ALD provided much better protective coatings for silver mirror samples than traditional physical deposition techniques.

"Atomic layer deposition performs significantly better," Phillips says. "The problem is that the systems used in the electronics industry are designed for silicon wafers, so they're too small for a telescope mirror."

Patent filed on concept

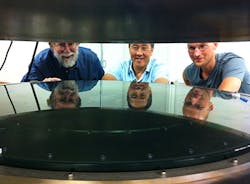

The results of the pilot study, which used an ALD system in Kobayashi's lab designed for microelectronics, convinced the team to design a larger system that could accommodate telescope mirrors. They filed for a patent on their concept and found an equipment vendor willing to work with them to build the system. The vendor, Structured Materials Industries (SMI; Piscataway, NJ), makes thin-film deposition systems for the microelectronics industry.

The new system was delivered to Kobayashi's laboratory in July, 2017 and has performed well in initial testing. The researchers will use the system to demonstrate that it works for telescope mirrors and other large substrates and to continue perfecting the coatings. The system can accommodate a mirror up to 0.9 m in diameter, and there is no reason the design could not be scaled up to accommodate larger mirrors or mirror segments, Phillips says. The 10 m primary mirrors of the twin Keck Telescopes in Hawaii are composed of hexagonal segments 1.8 m across, and the mirror segments for the Thirty Meter Telescope (TMT) will be 1.4 m across.

According to Bolte, the desire to use silver on the TMT mirror segments is a major driver of their research on new coating technologies. But he expects the technology will also be used to recoat the mirrors of existing telescopes. An aluminum-coated mirror lasts about three to five years before it needs recoating, a process that puts the telescope temporarily out of action.

"We hate to lose telescope time, and we lose a lot of nights recoating segments at Keck," Phillips says. "We'd like to have a silver coating that could last five to ten years."

At this point, the researchers are using a physical deposition process to put the silver coating on the mirror blanks along with an initial barrier layer to protect the silver while the mirror is transferred to the ALD system. Atomic layer deposition is then used for the final barrier layers.

"Right now, it's a hybrid process, but we're following the development of atomic layer deposition for the silver coating as well," Phillips says.

Source: https://news.ucsc.edu/2017/09/mirror-coating.html

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.