100,000 DPI printing process uses structured nanomaterials rather than color inks

New research from the University of Glasgow (Glasgow, Scotland) published in the journal Advanced Functional Materials outlines how its engineers have developed nanoscale plasmonic color filters that display different colors depending on the orientation of the light that hits them. Essentially, this technique allows the 'printing' of two entirely different, but exceptionally detailed, full-color images within the same surface area--something that the researchers say has never been done before using structural color techniques.

RELATED ARTICLE: Chemical reaction alters the colors of plasmonic prints

Instead of relying on dyes and pigments, as in traditional printing, structural color uses specially structured nanomaterials to render colors. The nanomaterials allow for much-higher-resolution prints that do not fade over time. A typical printed image in a magazine, for example, might consist of around 300 colored dots per inch of page, or 300 DPI. A page printed with structural color techniques, however, could reach a resolution of 100,000 DPI or more.

The University of Glasgow team's breakthrough comes from including an additional nanoscale element in the structural color process, created at the University's James Watt Nanofabrication Centre.

Biomedical engineering lecturer Alasdair Clark is the lead author of the research paper and said, "We've discovered that if we make colour pixels from tiny cross-shaped indents on a strip of aluminium film, the colour they display becomes polarisation-dependent, allowing us to encode two colours into a single pixel, and then select which colour is displayed by shining different polarisations of light at the surface. By changing the size and shape of the nanoscale indent, we can create a wide range of different colours at very high resolutions."

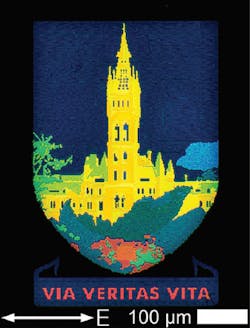

The team has demonstrated their technique with several examples, including a nanoscale image that shows the University's crest when the light reaches it in one orientation, and an image of the famous University tower when the orientation of the light is reversed.

Clark adds, "There are a lot of potential applications for our plasmonic colour technology, which we're really excited about. It's ideal for long-term data archival due to its ultra-high resolution, and because the colours won't fade even when exposed long-term to the harshest sunlight. We've worked out that we could store 1.46 Gb per square centimetre, so a single A4 sheet could hold more than 900 Gb of data. Secondly, the process to produce the plasmonic colours is difficult to replicate without access to dedicated facilities, so it could be ideal for creating a new kind of anti-counterfeiting material for banknotes. Lastly, it offers the possibility of developing new types of colour filters for digital photography."

SOURCE: University of Glasgow; http://www.gla.ac.uk/news/headline_549731_en.html

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.