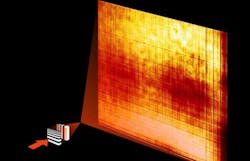

| Two perpendicularly oriented lenses focus an x-ray beam into a small spot. The object under investigation (not shown here) can then be placed into the optical path and its image recorded by the detector. (Credit: DESY, Andrew Morgan/Saša Bajt) |

Scientists at the Deutsches Elektronen-Synchrotron (DESY; Hamburg, Germany) have developed novel lenses that enable x-ray microscopy with record resolution in the nanometer regime.1 The lens uses a new material combination consisting of alternating layers of tungsten carbide and silicon carbide, with the layers decreasing in thickness as a function of position, allowing for focusing in one dimension. Two of these structures are then placed close together an crossed to form a lens that focuses x-rays in 2D, achieving a focus spot that has a diameter of less than ten nanometers (8.4 x 6.8 nm, to be precise). The researchers used this lens to image samples of diatoms, a form of marine plankton.

The research team was led by DESY scientist Saša Bajt from the Center for Free-Electron Laser Science (CFEL).

The DESY lenses are a form of specialized x-ray optics called multilayer Laue lenses (MLLs). The alternating layers of two different materials with nanometer thickness are prepared via sputter deposition. In contrast to conventional optics, MLLs do not refract light but work by diffracting the incident x-rays in a way that concentrates the beam on a small spot. To achieve this, the layer thickness of the materials has to be precisely controlled. The layers must gradually change in thickness and orientation throughout the lens. The focus size is proportional to the smallest layer thickness in the MLL structure. The new lenses consist of more than 10,000 alternating layers of tungsten carbide and silicon carbide.

RELATED: Normal-incidence multilayer Laue lens focuses hard x-rays

At beamline P11 of DESY's x-ray source PETRA III, the scientists produced high-resolution holograms of Acantharea, single-celled Radiolaria belonging to marine plankton and the only organisms known to form skeletons from the mineral strontium sulfate (SrSO4) or celestite.

Bajt's team has also used the lenses to image the biomineralized shells of marine planktonic diatoms. These single-celled organisms have intricate shells, which are highly complex and stable but also lightweight constructions. They consist of nanostructured silica, which has previously been observed in 2D analyses using electron microscopes. Most likely because of this structuring, the strength of the silica is exceptionally high – ten times higher than that of construction steel – although it is produced under low temperature and pressure conditions.

The new lenses can be used in a wide range of applications including nanoresolution imaging and spectroscopy. “Since we now know how to optimize the lens design, our work paves the way to ultimately reach the goal of one nanometer resolution in x-ray microscopy,” says Bajt.

Source: http://www.desy.de/news/news_search/index_eng.html?openDirectAnchor=1324

REFERENCE:

1. Saša Bajt et al., Light: Science and Applications (2017); doi: 10.1038/lsa.2017.162