Optaglio introduces nanotechnology-based holograms that can't be counterfeited

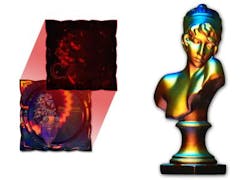

Optaglio (Lochovice, Czech Republic), which makes high-resolution security holograms, has unveiled several new optical features that enable users to identify genuine holograms immediately and that cannot be imitated at all, according to the company. Some of them were implemented in holograms shown at the SDW 2017 Expo (June 26-28; London, England).

The ongoing race between document falsifiers and document protectors is mostly based on emulating visual effects of security elements such as holograms. If the falsifier manages to produce something so close to the genuine hologram that ordinary users are confused, his/her counterfeiting effort will likely be successful. It is the main reason hologram producers need to introduce new effects regularly to maintain their advantage against attackers.

Optaglio uses e-beam lithography with an extremely high resolution of more than 2.5 million DPI (dots per inch). The result of several years of intensive research in Optaglio Labs, the technique allows the fabrication of very high-resolution diffraction gratings, and consequently unique visual effects. Each kind of effect is based on a special software algorithm.

"For imitating our hologram, you need access to our lithograph or a very similar machine, our software with same algorithms implemented, and data from the previous session. To sum up, imitation is impossible," says Tomáš Karenský, senior research manager at Optaglio.

The latest visual effects include: 1) A fluent change instead of abrupt switching between pictures during hologram tilting. This fluent moving can work in a separate axis from the tilt axis. 2) The emergence of a new object from the hologram background after illumination with monochromatic light under a precisely defined angle. Further effects are currently in the final phase of testing and will be marketed later this year.

For more info, see: www.optaglio.cz

Source: Optaglio

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.