Luminit offering custom micro-optic fabrication capability for lidar and other applications

Luminit (Torrance, CA), a privately held company specializing in fine optics and holographic light-shaping diffusers, announces new Light Shaping Micro Optics capabilities for light detection and ranging (lidar), time-of-flight (TOF), facial ID, and eye/head tracking applications. In-house direct-writing of masters, along with greyscale photolithography and advanced microscopy tools, allow pixel-by-pixel design and write capabilities for a full-range of micro-optics solutions at high-volume production levels.

RELATED ARTICLE: How microoptics are changing industrial laser applications

"LIDAR, time of flight, facial recognition and similar advanced technologies are growth areas, and Luminit continues to develop high-performance optics to meet market demand," says Suleyman Turgut, VP of sales and marketing at Luminit. "With Light Shaping Micro Optics, we can design, master, replicate, test and measure under one roof and our customers benefit from reduced time-to-market and simplified supply chains."

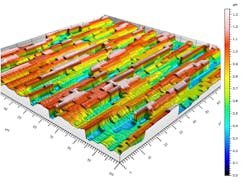

Luminit's new capability in greyscale photolithography allows the creation of advanced refractive (micro lenses, prisms, Fresnels) and diffractive optics (CGH, phase plates) with feature sizes down to 1 micron. Optical outputs include flat-top intensity profiles, structured lighting (random dot generators, pattern generators), and custom illumination shapes (square, rectangular, logos). Luminit is now able to manufacture a variety of precise digital and analog micro-optics that can later be replicated on a variety of plastic and glass substrates depending on thickness, temperature, and volume requirements.

According to the company, Luminit's new offering of Light Shaping Micro Optics provides customers with the ability to bring their designs straight from concept to high-volume production in a matter of weeks.

SOURCE: Luminit; https://www.luminitco.com/about/press

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.