A team of researchers led by Zhaoyang Li from the Key Laboratory of Ultra-Intense Laser Science and Technology at the Shanghai Institute of Optics and Fine Mechanics in China are enhancing the focus of petawatt (a.k.a. ultra-intense) lasers via hyperbolic mirrors (see video). This is a big deal because it’s the first time a hyperbolic mirror—an optical element—is being applied to strong-field laser physics.

Peak power measures the intensity of ultra-intense lasers before focusing, but what’s truly important for experiments is a laser’s focused intensity on the target. Focused intensity, not peak power, determines an ultra-intense laser’s real capability.

“Lasers are one of the most important inventions of the 20th century, and the ultra-intense laser takes the high intensity of lasers to the extreme,” says Li, a professor and deputy director of the Key Laboratory of Ultra-Intense Laser Science and Technology. “Physicists predict ultra-intense lasers can play an important role in the exploration of the nature of matter and the origin of the universe. My interest and curiosity in these basic physics questions makes me happy to be working on ultra-intense laser research for strong-field laser physics.”

Ultra-intense laser design

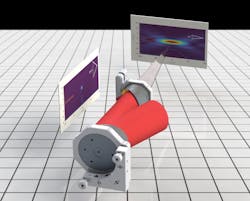

Ultra-intense lasers are usually focused onto experimental targets using off-axis parabolic mirrors, and their beam aperture ranges from 150 to 500 nm (with a focal spot size of 2 to 10 wavelengths).

By combining a rotational hyperbolic mirror to the parabolic mirror, Li and colleagues discovered they could significantly reduce the laser’s focal spot size.

“A hyperbola is a type of curve with two foci, characterized by the fact that a line directed to one focus will pass through the other by reflection through the hyperbola,” Li explains. “Using this feature, combining a hyperbolic mirror with a parabolic mirror allows light that would otherwise converge to one focus to converge to the other.”

Optimizing the parameters of the hyperbolic mirror enables the angle of convergence to be dramatically increased, which significantly reduces the focal spot size to a single wavelength.

Focusing a focal spot to the smallest possible size “can significantly enhance the experimental capabilities of an ultra-intense laser and maximize the performance of a laser facility,” Li says. “It’s more economical, efficient, and simpler than the traditional methods of continuously increasing the energy of the laser facility or decreasing the duration of the laser pulse, because the latter two are difficult and extremely costly.”

Compared with using a single parabolic mirror for focusing, Li points out the hyperbolic mirror method solves the traditional challenges of obtaining very small focal spots and can reduce the focal spots almost to the ultimate minimum—a single wavelength size.

When putting its design to the test, the team was surprised to discover it could increase the focused intensity of ultra-intense lasers by a factor of 20 to 30 directly. “Importantly, combined with our previously proposed wide-angle noncollinear optical parametric chirped-pulse amplification (WNOPCPA) method, we expect it to reach the highest intensity condition of ultra-intense lasers—focusing all laser energy into a spatiotemporal focal cube edged by the laser’s center wavelength,” says Li.

Combining these two techniques allows the researchers to achieve “both the shortest pulse of a single-cycle pulse and the smallest focal spot of a single-wavelength focal spot at the same time,” Li says. “It results in the highest focused intensity of an ultra-intense laser facility. Increasing the performance of the ultra-intense lasers to the upper limit of engineering hasn’t been achieved before, and there’s also the possibility of reaching the Schwinger limit (quantum electrodynamics critical field) in the future.”

The biggest challenges involved in this work for the team were “machining accuracy, mounting/adjusting accuracy, and possible damage of the hyperbolic mirror, especially the large-aperture hyperbolic mirror for 10-petawatt lasers,” Li adds.

Improved focus for petawatt lasers

The team’s technology can be used directly in petawatt lasers around the world—like the ELI-NP in Romania, the Shanghai Super-Intense Ultrafast Laser Facility in China, and the NIF-ARC Laser at Lawrence Livermore National Laboratory in the U.S.—to increase their focused intensities and provide more extreme light conditions for strong-field laser physics than ever before.

Li and colleagues are now working to increase the focused intensity of their 10-petawatt laser at the Shanghai Super-Intense Ultrafast Laser Facility from 1022 W/cm2 to 1023 W/cm2 or even 1024 W/cm2 via this method.

“Light fields in single-wavelength tight focusing are still being explored,” says Li. “And we’re now fabricating a large-aperture hyperbolic mirror, which will be used for a single-wavelength tight focusing experiment with our 10-petawatt laser.”

FURTHER READING

Z. Li, Y. Liu, X. Guo, Y. Leng, and R. Li, Adv. Photon. Nexus, 3, 3, 036002 (Mar. 2024); https://doi.org/10.1117/1.apn.3.3.036002.

Z. Li and J. Kawanaka, OSA Contin., 2, 1125–1137 (2019).

Z. Li, Y. Kato, and J. Kawanaka, Sci. Rep., 11, 151 (2021); https://doi.org/10.1038/s41598-020-80435-6.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.