UV meta-holograms: Nanoparticle concentrations and solvents affect pattern transfer, effectiveness

A team of researchers led by Professor Junsuk Rho at Pohang University of Science and Technology (POSTECH) in South Korea recently set out on a quest to find the printing material best suited to craft UV metasurfaces—and discovered the optimal conditions to mass-produce UV holograms (see video).

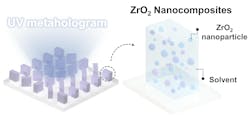

Metasurfaces tend to be produced using nanoimprint lithography (NIL), which works akin to a stamp generating replicas from a single mold. But there’s a serious problem with this process: the resin currently used as the printing material has a low refractive index and it inhibits efficient light manipulation. To boost its refractive index, researchers are exploring adding nanoparticles to the UV-curable resin.

“UV metasurfaces are distinguished by their unique capabilities to manipulate UV light—and it makes them invaluable in various applications such as imaging, display technology, and biosensing,” says Rho, a professor of chemical engineering and mechanical engineering.

The design of these metasurfaces involves structures significantly smaller than the wavelength of UV radiation, which “necessitates the use of costly nanopatterning techniques to achieve the required nanoscale resolution and high aspect ratios,” Rho explains. “Beyond this, the scarcity of materials with high transparency within the UV range presents further challenges. These factors make conventional methods of producing UV metasurfaces impractical for mass manufacturing.”

To overcome these obstacles, Rho’s team developed a novel one-step NIL fabrication method that uses high-refractive index (n) nanocomposites made of dielectric nanoparticles to enhance the effective refractive index of the printed structures while replicating mold patterns as effectively as traditional resins.

A little meta-atom background

Typically shaped as rectangular nanorods, anisotropic meta-atoms possess unique properties where the rotational angle significantly influences the phase of circularly polarized light passing through—behavior known as the Pancharatnam-Berry phase (PB phase).

“These meta-atoms function by altering the effective refractive index based on the polarization state across their long and short axes,” says Rho. “Notably, complete 2π phase manipulation of cross-polarized light is facilitated through the differential effective refractive indices for x- and y-linear polarizations.”

This adjustment causes a reversal in the “handedness” of circularly polarized light and generates a π phase disparity between two polarization states. To enhance the efficacy of metasurface holography, it’s essential to optimize the cross-polarization interactions.

“We use these phase control strategies to develop UV meta-holograms using the PB phase,” Rho adds. “The method doesn’t achieve complete wavelength independence, but offers relatively broadband properties compared to other phase control methods. It’s crucial to note: Hologram production with anisotropic meta-atoms using metasurface holography is contingent upon the incident light being circularly polarized.”

Design work

In their design process, Rho’s team used rigorous coupled-wave analysis (RCWA) to simulate the transmission properties of meta-atoms made from zirconium dioxide (ZrO2) nanocomposites.

“The PB phase concept allows us to fully modulate the 2π phase coverage within the UV region,” Rho says. “This approach allows us to achieve the desired phase profile physically. Light transmitted through these meta-atoms exhibits converted ‘handedness’ of polarization, or cross-polarization, which includes a phase delay. The amplitude of the cross-polarized component is referred to as the ‘conversion efficiency’ and is directly linked to the meta-atom’s performance.”

The goal? Design high-efficiency meta-atoms that operate within the near-UV region—around 325 nm. “The ideal PB phase meta-atom is designed to provide a π phase difference between the x and y components of the electric field (Ex and Ey)—functioning effectively as a half-wave plate,” Rho says. “We’ve confirmed that our designed meta-atoms indeed provide this π phase difference and operate as perfect half-wave plates that serve as ideal PB phase meta-atoms. Thanks to near-zero extinction coefficient of the ZrO2 nanocomposite, these meta-atoms exhibit high transmittance and minimal absorption within the UV range.”

This work taps a conventionally exploited design strategy, but focuses on overcoming processing limitations that previously restricted the implementation of metasurfaces within the UV spectrum. Building upon this study, optimized designs and new design methodologies should expedite commercialization of UV metasurfaces.

High-fidelity UV meta-holograms

Rho’s team focused on refining ZrO2 nanocomposites to produce high-fidelity UV meta-holograms using NIL, and explored different ZrO2 nanoparticle concentrations/solvent interactions within the nanocomposites to determine the most effective settings.

“Our pivotal discovery: an 80 wt% ZrO2 nanoparticle is ideal and offers excellent refractive properties and high pattern fidelity,” says Rho. “Lower concentrations resulted in diminished pattern clarity and fidelity due to a lack of sufficient mechanical support during the NIL process. On the other hand, higher concentrations led to nanoparticle agglomeration, which causes clusters that interfered with the mold cavities.”

Beyond this, the researchers observed the effects of solvent interaction with polydimethylsiloxane (PDMS) on pattern transfer. “By creating microscale soft molds, we could visually assess the pattern distortions caused by solvent absorption,” Rho adds. “Our tests show that acetone and methyl isobutyl ketone (MIBK) based nanocomposites had a lower swelling ratio than those with methyl ethyl ketone (MEK), which adversely affected PDMS properties, increased surface roughness, and led to inconsistent nanocomposite spreading.”

An uneven distribution affected the pressure applied during imprinting and reduced the fidelity and clarity of the transferred patterns.

“Ultimately, meta-holograms produced with acetone and MIBK show significantly clearer and more vibrant images compared to those made with MEK, the conversion efficiencies of 62.3% and 61.5%, respectively, vs. 51.4% for MEK,” Rho says.

Challenges along the way

One of the primary challenges the team encountered was achieving uniform nanoparticle dispersion within the nanocomposite.

“Nonuniform distribution leads to significant variations in the mechanical properties of the molds and impacts the fidelity of the pattern transfer,” says Rho.

Interactions between the nanocomposites and different solvents presented another significant challenge. “Each solvent affects the PDMS in the molds differently by altering their surface properties and swelling effects, which can lead to increased surface roughness or uneven pressure during imprinting,” Rho explains. This variation complicates the process, because each solvent requires individual adjustments.

Another hurdle ahead is scaling the process for larger-scale production while maintaining high resolution and efficiency. As they move toward commercial application, maintaining the precision required for high-quality meta-holographic images on a larger scale presents a challenge: ensuring consistent nanocomposite quality and handling across larger substrates.

“Addressing these challenges involves not only refining our materials science and engineering approaches, but also analyzing the intricacies of nanoparticle behavior and solvent interactions more effectively,” Rho adds.

Better displays and security ahead

The team’s research highlights how the manipulation of nanoparticle concentration and solvent choice can enable improvements in NIL. “Our UV metasurfaces, made from ZrO2 nanocomposite structures, are produced through an efficient and cost-effective printing technique,” Rho says.

By combining nanocomposite meta-atoms with established tuning methods, the team created versatile meta-holograms. “These advances pave the way for their integration into next-generation holographic displays and extend their applicability to augmented and virtual reality technologies,” Rho says. “Such applications demonstrate the practical utility of our research to enhance the visual and interactive experiences in these cutting-edge fields.”

The goal now is to advance the application of multiplexed UV meta-holograms by exploring the use of ZrO2 PER-based NIL. Unlike conventional meta-holograms, which typically generate a single holographic image, Rho’s team wants to try to multiplex multiple images within a single-layer device.

By using a one-step NIL platform, the researchers plan to directly replicate UV meta-holograms to enhance throughput and reduce production costs. “Our future work will focus on UV meta-holograms capable of switching outputs based on the ‘handedness’ of the circularly polarized input light, alternating between left-circularly polarized and right-circularly polarized states,” Rho says. “We’ll design these meta-holograms to allow for independent phase control and the generation of holograms.”

“Our approach is expected to mark a significant breakthrough in optical devices—enabling them to use spin information to achieve dynamic functionalities,” says Rho. “The potential applications of this technology are vast and range from optical security to multifunctional anticounterfeiting measures within the UV region.”

FURTHER READING

H. Kang et al., Microsyst. Nanoeng., 10, 53 (2024); https://doi.org/10.1038/s41378-024-00681-w.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.