A team of engineers from Pohang University of Science and Technology (POSTECH; South Korea) and Korea University has designed a transparent film using the principles of radiative cooling, described as a passive process that uses photon heat flow to remove energy and randomness (see video).

In relation to the new transparent film, radiative cooling can allow heat to be naturally released and surfaces cooled without external power. Integrating the cooling effect into surfaces such as glass has long been a challenge because films typically transmit solar heat themselves, which can significantly limit effective cooling.

“Previous transparent radiative coolers suffer from inevitable irradiation energy from sunlight due to its transmissivity in the visible regime,” says Junsuk Rho, a professor with POSTECH’s departments of Chemical Engineering, Mechanical Engineering, and Electrical Engineering. “Simply put, it has been a give and take between solar irradiation and visibility for transparent radiative coolers.”

The development

To overcome the challenges, the researchers have taken note from screens designed to cover the opening of a window and featuring many tiny holes that allow air and light in, while keeping insects out.

“We have conceptualized from window screens that prevent insects from coming inside, but still keeps visibility to the person inside,” Rho says. “In the same way, metallic mirrors with holes can prevent too much solar irradiation and maintain visibility.”

The radiative cooling film consists of three layers. First, a window screen reflector made of a silver film perforated with micro-sized holes. The size of the holes can be controlled so solar irradiation can be effectively reduced.

Another of the three components is a Bragg mirror, a mirror structure consisting of an alternating sequence of layers of two different optical materials that reflects near-infrared (near-IR) light. It has been optimized to make sure that near-IR light (in the 0.74- to approximately 1.4-µm range) is mostly reflected.

The third layer is a silicon-based polydimethylsiloxane (PDMS) coating, which is used to emit heat into the atmospheric window (a range of 8 µm to about 13 µm).

Rho says this combination dissipates heat, while maintaining the film’s transparency and visibility, and decreasing energy consumption. Basically, “the film can perform radiative cooling at the highest level,” he says.

What’s so great, and what’s next?

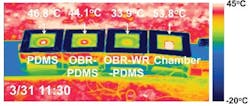

Compared to conventional PDMS-coated glass, the team’s radiative cooling film showed temperature decrease of 22.1°C (71.78°F). And energy from solar irradiance has demonstrated the lowest temperatures among any transparent radiative cooling studies.

Rho says this shows the new film could be used for applications in which both visibility and cooling are required.

At this point, the team is working to advance its research regarding radiative cooling technology. “Radiative cooling is a technology that has been studied for quite a while,” Rho says. “There are various applications such as fabrics, electric- and temperature-switchable films, and so on. We are surveying these applications and trying to figure out the challenges they are facing.”

FURTHER READING

B. Ko et al., Adv. Funct. Mater. (Aug. 12, 2024); https://doi.org/10.1002/adfm.202410613.

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.