Advances in Optical Systems: Chalcogenide’s place in the infrared optical materials spectrum

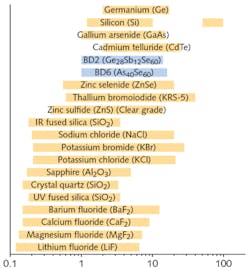

A wide variety of infrared (IR) optical materials is available to the designer (see Fig. 1)—when designing IR optics, a number of factors must be considered in regard to what materials to use. These factors include refractive properties, optical transmission, athermal performance, hardness/durability, environmental susceptibility, weight/density, fabrication techniques, and cost. Some of these factors are interrelated. For example, for some materials, their optical transmission is high at room temperature, but is reduced at higher temperatures. With all of this in mind, material options need to be considered carefully when designing IR optics.

BD6 chalcogenide

For optical engineers and lens designers, chalcogenide (ChG) is quickly becoming a top choice among IR materials. Chalcogenide is an amorphous glass and is easier to work with than conventional IR crystalline materials. A number of different chemical composition choices exist for ChG, but BD6, composed of arsenic and selenium (As40Se60), represents the best choice from a cost and ease-of-manufacturing perspective.

BD6 (see Fig. 2) has numerous advantages in comparison to other IR materials, including high refractive index, low weight, low cost (thanks, in part, to a germanium-free composition), athermal performance, high transmission, and flexible fabrication. BD6 has a refractive index of 2.75 to 2.85 across the IR spectrum, making it a very suitable material for powered optics. With a density of 4.63 g/cm3, BD6 has a low weight (as compared with other IR materials), making it ideal for weight-sensitive applications such as aerospace. The cost of BD6 is less than most other durable IR materials. With a low thermo-optic coefficient (dn/dt) of 30 × 10-6, BD6 can help designers achieve better athermal performance. Uncoated BD6 glass has transmission above 60% across the entire IR spectrum. ISP Optics offers a high-efficiency broadband antireflective (HEAR) coating for BD6 with an average transmission of more than 95% for the longwave-IR (LWIR: 8–12 µm) band.Another advantage of BD6 glass over other IR materials is its flexibility with regard to fabrication techniques. In addition to conventional grind and polish techniques, the relatively low Tg (~200°C) of BD6 allows precision glass molding to be used for lens fabrication. Similarly, BD6 glass is neither too hard nor too brittle and, as such, it can be diamond-turned as well. ISP Optics and LightPath are capable of using all three of these techniques for BD6 fabrication. As such, the vast majority of customer cost, lead time, and performance requirements can be accommodated.

Other IR materials

While BD6 is a superior choice for many IR optical applications, ISP Optics does offer IR optical components fabricated from a number of other materials. These materials include semiconductors, such as germanium (Ge), silicon (Si), gallium arsenide (GaAs), and cadmium telluride (CdTe); zinc compounds, such as zinc sulfide (ZnS) and zinc selenide (ZnSe); water-soluble crystals, such as potassium bromide (KBr), sodium chloride (NaCl), and potassium chloride (KCl); fluorides, such as magnesium fluoride (MgF2), calcium fluoride (CaF2), and barium fluoride (BaF2); and other materials, such as fused silica and sapphire.

Prior to the rise in popularity of ChG, semiconductor materials have been the traditional workhorse IR materials. Germanium, for example, has historically been the most popular infrared material—it has several advantages, including the highest index of refraction (~4) of all IR materials, it is easily diamond-turnable, it naturally blocks UV, visible, and near-IR (up to ~2 µm) light, and it also has high transmission in the MWIR and LWIR bands. Germanium does have its disadvantages, however, including a high material cost, a large thermo-optic coefficient (resulting in poor athermalization), and a very high density and thus weight. In particular, Ge is prone to thermal runaway, whereby the material becomes completely opaque at higher temperatures. Other semiconductor materials do not have the same tradeoffs as germanium. For example, Si has a very low density, making it more appropriate for weight-sensitive applications. However, it absorbs heavily in the 8–12 µm range, making it inappropriate for use at these longer wavelengths.

Zinc compounds offer a number of benefits for IR applications. Zinc selenide (see Fig. 3), for example, offers high transmission across the IR spectrum (out to 16 µm), high refractive index, strong resistance to thermal shock, and is easily diamond-turnable. This material’s resistance to thermal shock makes it very suitable for high-power laser applications. Zinc sulfide, the other zinc compound utilized as an IR material, offers high transmission in the IR out to 12 µm, low absorption, and is diamond-turnable. In addition, while both ZnSe and ZnS offer transmission in the visible as well, they are both not moldable and are even more costly than Ge.For very cost-sensitive IR optical applications, water-soluble crystals are potentially a good option. They are among the least expensive optical materials that have high transmission deep into the IR as well as in the visible. While water-soluble crystals do have their advantages, they are not without their drawbacks as well. They are highly hygroscopic materials and, as such, require humidity-protective coatings for the vast majority of applications. In addition, many of these materials are soft and brittle, which means they are not diamond-turnable. The primary application for this class of IR materials is for windows in gas/liquid sample cells for spectrometers. In addition, KCl is used to craft protective windows for carbon dioxide (CO2) lasers, as KCl has a low refractive index at 10.6 µm and a high damage threshold.

For IR applications where high optical throughput is a priority, CaF2 can be advantageous. With an uncoated transmission above 90% out to 7 µm, CaF2 is highly transmissive in the near-IR and MWIR bands. As such, this means that fabrication is often simplified when using this material, as AR coatings often aren’t needed. While CaF2 is a brittle material, it is diamond-turnable. Unfortunately, CaF2 is also fairly hygroscopic and, as such, does degrade due to moisture. Barium fluoride, like CaF2, has an uncoated transmission above 90%, but out even further than CaF2—out to 9.5 µm. Also, like CaF2, BaF2 is diamond-turnable. However, BaF2 is very susceptible to thermal shock and is even more expensive than CaF2. Unfortunately, fluoride materials are not moldable.

There are additional materials that are suitable for IR optics. Water-free (also known as IR-grade) fused silica, for example, is an amorphous glass material that has good transmission in the near-IR (out to 3.5 µm) and good athermalization properties. Unfortunately, because of the very hard nature of this material, it is not diamond-turnable. This makes it more difficult and costly to fabricate aspheric optics using fused silica. Sapphire is an even harder material (it is second only to diamond in terms of hardness), which means it is not diamond-turnable. It is, however, very durable—it can withstand extremely harsh environments and has a melting point that exceeds 2000°C. Sapphire also features a high uncoated transmission out to 5.5 µm. With a low dn/dT, sapphire is well suited for athermal applications.

While there are a number of materials available for use when designing IR optics, chalcogenide BD6 has a number of advantages as compared with conventional legacy materials. These advantages include low weight, low cost, high transmission, flexible fabrication options, and others. Current IR applications are more demanding than ever—however, the great variety of optical materials now available enable the design choices needed to meet the demands of these applications.

ACKNOWLEDGEMENT

ISP Optics is a wholly owned subsidiary of LightPath Technologies.

Alan Symmons | Executive VP of Operations, LightPath Technologies

Alan Symmons is executive VP of operations at LightPath Technologies (Orlando, FL).

Andrew Locke | Applications Engineering Manager, LightPath Technologies

Andrew Locke is applications engineering manager at LightPath Technologies (Orlando, FL).

Mark Lifshotz | Head of Strategic Business Development, LightPath Technologies

Mark Lifshotz is Head of Strategic Business Development at LightPath Technologies (Orlando, FL).