Optically pumped single-mode laser enables integrated device biosensor

Interferometry is a sensitive optical detection method quantifying changes in optical path length and is useful for biological and biochemical detection, because biological specimens tend to be optically transparent.

One general interferometric sensor design approach involves monitoring output intensity as the refractive index changes when a target analyte is introduced to one interferometer leg. An interferometer, though, requires precision optical alignment, generally of a laser source. “Precision optical alignment” is a term that doesn’t conjure images of rapid and inexpensive clinical testing.

A team of Austrian researchers has developed a diode-pumped lab-on-a-chip design capable of sensing analyte concentrations under a microgram per milliliter, using an inexpensive, misalignment-tolerant diode laser as a pump.

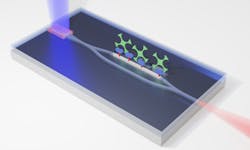

Building on previous work, the team uses the diode as an optical pump for a single-mode organic solid-state laser (OSSL) integrated into a silicon dioxide/silicon nitride (SiO2/SiN) photonic circuit combined with a microfluidic device. With the laser output coupled into a Mach-Zehnder interferometer (MZI), the device provides high sensitivity with speed and ease of use, opening the door for future clinical applications.

Need for speed

Medical treatment decisions are driven by knowledge, often obtained through laboratory testing of biomedical samples—fluids or tissue. Ideally, an analytical method would be capable of detecting low analyte concentrations in small samples, and doing so rapidly, inexpensively, and easily.

As is often the case, these requirements are somewhat contradictory. For example, optical interferometry can detect very small changes in the index of refraction, so a typical sensor architecture relies on capturing an analyte in one interferometer leg while monitoring the transmitted intensity change at the interferometer output. The analyte’s presence modifies the index of refraction, so the phase difference between the measurement beam and the reference beam varies, resulting in an intensity change.

To achieve maximum sensitivity with a small sample, this approach requires accurate and efficient coupling of a single-mode laser into a miniaturized interferometer. This, in turn, demands either integrating a single-mode semiconductor laser directly into the miniaturized device, or precise alignment of an external laser source to the interferometer input. These approaches add cost or both cost and difficulty, respectively, to the analysis.

A research team led by the Austrian Institute of Technology (AIT; Vienna, Austria) has overcome those challenges by incorporating a single-mode OSSL into an integrated photonic/microfluidic device.

The optical waveguide is fabricated by plasma-enhanced chemical vapor deposition of SiN on a SiO2 layer built on a silicon wafer substrate, which is then topped with another SiO2 layer—except in two regions: the laser cavity and one leg of the MZI. A 300 × 75 µm region over the laser cavity is then filled with dye-doped polymer. A distributed feedback grating structure is built into the laser cavity to constrain to single-mode operation at 605 nm. The output is coupled to a tapered waveguide 375 × 160 nm in cross-section, which links to a Y-branch separating into two interferometer legs, which are then recombined through another Y-branch structure. A 10 mm length over one of the interferometer legs is left uncovered; when mated with the microfluidic channels, the analyte can be introduced right onto the MZI waveguide. The output is coupled into a multimode optical fiber and sent to a detector.

Toward the clinic

OSSLs are relatively insensitive to the angle of optical pumping, so the organic dye in the cavity can be excited by an inexpensive multimode blue diode laser. The key here is the incorporation of the distributed-feedback structure into a silicon nitride photonic integrated platform, which effectively converts the short coherence length pump laser into an in-device coherence length long enough to ensure high contrast at the interferometer output. This configuration is the first dye-doped single-mode laser suitable for coupling directly into an optical waveguide.

After calibrating the device with various concentrations of sodium chloride solution in the analyte arm, the researchers functionalized this region with a streptavidin/biotin complex and then introduced a complementary analyte. They monitored the phase changeover for periods of up to 20 minutes, demonstrating the ability to measure concentrations as low as 0.5 μg/mL. “Our multidisciplinary team was gratified to see theoretical work, design efforts, and material development result in a real biofunctionalized device that performs as predicted,” says Florian Vogelbacher, an AIT team member now at the Chinese Academy of Sciences in Beijing.

Rainer Hainberger, senior scientist at AIT, notes their next steps will include optimizing the laser resonator to reduce the lasing threshold and decrease the dye photobleaching. “Now that we’ve demonstrated a cost-efficient solution to create coherent light on an integrated photonic sensor platform,” he says, “we believe photonic integrated devices will be more attractive for real-world biosensing applications.”

Richard Gaughan | Contributing Writer, BioOptics World

Richard Gaughan is the Owner of Mountain Optical Systems and a contributing writer for BioOptics World.