Evolving nanopositioning systems expand application base

We've all heard about NASA’s James Webb Space Telescope and for good reason. Its deployment late last year will play a pivotal role in helping us better understand our planetary system and beyond. This infrared observatory orbits the sun about 1 million miles from Earth, with its sights set on finding the first galaxies formed in the early universe as well as stars forming new planetary systems. One day, it may discover potentially habitable exoplanets.

Quite literally going where no man has gone before, the James Webb is building upon discoveries already made by the Hubble Space Telescope. It’s expected to surpass the capabilities of the Hubble Space Telescope significantly—in fact, it can view objects in space up to 100 times fainter than the faintest objects detectable by Hubble.

This can all be traced back to nanopositioning technology.

Ins and outs of nanopositioning

Nanopositioning systems work in the nanometer and sub-nanometer scales, moving and arranging stages and samples with incredible precision. They can position within tens of nanometers, and potentially single-digit nanometers, making them ideal for applications that require extremely precise measurement, such as space telescopes and microscopes. And the scope of nanopositioning systems’ capabilities goes beyond that.

Comprised of various components—depending on the application—nanopositioning systems can be used as part of an integrated approach to motion control, notes Shannon Ghorbani, a member of the technical sales team at Mad City Labs (Madison, WI). And they’re used for more than just nanometer resolution.

Nanopositioning system components often feature linear motor stages, air bearing stages, voice-coil drives, and magnetic levitation systems. All have become standard for providing repeatable nanometer step resolution, and are able to overcome challenges such as friction, lag times, and instability, which are common with conventional motorized positioners.

Piezo stages are another component of some nanopositioning systems and are known to offer “the best dynamics and accuracy” with their core composition of piezo actuators, flexures, and position sensors. According to Ghorbani, in a piece presented at a meeting of the American Physical Society, this combination, in conjunction with closed-loop feedback control, can “significantly [improve] stability, resolution, and repeatability” as opposed to other nanopositioning system parts.

He notes the piezo actuator component is essentially the driving mechanism of the nanopositioner system. These actuators can change dimension in response to an applied voltage. They also possess traits such as corkscrewing; this is the twisting motion of a bare piezo actuator that is an inherent characteristic, which can be corrected with flexure-guided stages.

Another trait of piezo actuators is called creep, which happens when the applied voltage is applied or withdrawn. “The piezo actuator tends to continue moving forward or backward, depending on the direction of motion,” Ghorbani says. “For the user, creep looks like the positioner is continuing to move. Fortunately, this effect can be mitigated with position sensors and closed-loop feedback control.”

He cites hysteresis—defined as the phenomenon in which the value of a physical property lags behind changes in the effect causing it, as when magnetic induction lags behind the magnetizing force—as “the nonlinear movement inherent to piezo actuators.” The actuator can take a slightly different path with each movement. For example, Ghorbani notes, “when a piezo nanopositioner’s applied voltage is increased, it moves in non-linear fashion to reach its destination point. When the applied voltage is reduced, the nanopositioner will return to its original point via a slightly different path, also nonlinear. To promote precision motion, the positioner needs to have linear, predictable motion. When these three characteristics are mitigated, piezos are an ideal actuator for nanometer precision motion.”

The flexure component—essentially a spring stretching and contracting, connected to other components—in piezo stages offers friction-free guiding that keeps motion in just a single direction. Ghorbani says “motion along each axis is guided by a single directional flexure pattern, allowing smooth, continuous motion.” Flexures allow the system to produce smoother and highly repeatable motion with low positional noise.

Position sensors in such piezo stage systems, used to sustain a desired position as part of closed-loop control, counteract the actuators’ inherent creep and hysteresis.

Closed-loop piezo nanopositioners have become strong candidates for higher accuracy, with their ability to provide sub-nanometer resolution as well as ranges from just a few microns to hundreds of microns and 1 nm (or better) resolution. Ideal for microscopy, such systems’ highly linear sensors allow improved precision, “gauged as linearity error, and can be measured with a traceable displacement interferometer.”

Piezoelectric nanopositioning actuators date back to the 1970s, when PI (Physik Instrumente; Auburn, MA) began developing them. According to company vice president Stephen Vorndran, it was “the only technology capable of delivering nanometer precise motion” at that time, with application fields mainly in optics and physics. Semiconductor research is another original and now longstanding application. In fact, he says the semiconductor industry, “with its relentless pursuit of smaller features (currently in the single-digit nanometer range), is still one of the driving forces for ultrafast and ultra-precise nanopositioning equipment.”

The pool of functions for piezo-based and other nanopositioning systems is expanding, too, into some extreme applications.

Expanding uses

“We continue to see the deployment of nanopositioning systems into wider ranges of products where precision motion is of paramount importance,” says Dr. Jenice Con Foo, marketing director for Mad City Labs. “The applications for this are highly varied.”

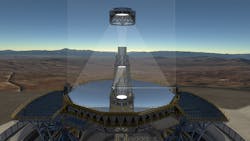

The James Webb Space Telescope’s successful deployment is a great demonstration of the importance of a strong nanopositioning system, Vorndran says. Developed by PI, the system used to assemble this telescope involves a high-precision, 6-axis (various linear stages range from one to six axes of motion) robotic hexapod, used to align the 18 large mirror segments (see Fig. 1). It “provides high force and ultra-high precision” to align the mirror segments “on a hinged surface over 21 feet in diameter.” All 18 pieces must work as a single mirror, so they must be positioned efficiently and accurately.

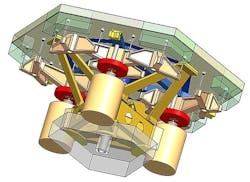

Other structures employing PI nanopositioning components include the European Southern Observatory’s Extremely Large Telescope (ELT; see Fig. 2). According to Vorndran, more than 2000 nanopositioning hybrid actuators align the 798 mirrors of this telescope (the largest optical telescope in the world; see Fig. 3).Optics, lasers, and all other components of space-based telescopes must move with “exceptional control resolution,” according to Ghorbani and fellow researcher Dr. James MacKay, director of product development at Mad City Labs. They note that “as the distance between the apparatus and the light source increases (i.e., the light gets dimmer), system demands for precision and stability also increase,” making accurate, reliable nanopositioning systems crucial.

Ultra-precise positioning is necessary for ground-based telescopes as well, as they “must contend not only with the planet’s movement, but with atmospheric interference. Thus, astronomers use yellow laser light to create artificial guide stars high above the Earth, using the point of light as a basis by which to correct their optics for atmospheric errors. Air in the atmosphere, though, is not uniform, and the beam must be adjusted to account for these changes.” This requires a precise motion system.

“Nanopositioning capabilities in ultra-precise laser beam steering mirrors are also essential for all of the satellite-based optical networks that are currently being developed,” Vorndran says, adding that another “really important” application area is photonics components test and manufacture. “Here, the precision and speed of true nanopositioning capabilities help push the limits of fiber optical data transmission and optical computing. Quantum computing is another novel technology that requires nanopositioning equipment.”

As for the future, he notes, “with ever-shrinking components and higher demands on performance, nanometer-precise motion control with high throughput will be getting more important than ever before. This comprises all high-tech fields, from biotechnology and genomics to laser processing, photonics, and semiconductors.”

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.