Large-FOV 2D voice-coil mirror enables applications in lidar and surveillance

Beam-steering components are often used in conjunction with lasers, but can also be used with cameras in imaging applications. Applications of beam-steering mirrors range from additive manufacturing, augmented and virtual reality (AR/VR), medical, and metrology to machine vision, surveillance, and autonomous vehicles.

In this article, the focus is only on components that work in reflection and can steer light in two axes in nonresonant mode for “point-and-shoot” applications or dynamic scanning limited to less than a few hundred hertz. Solid-state beam-steering devices such as optical phased arrays,1, 2 as well as video-display devices with resonant scanners capable of video scanning rates of a few kilohertz, are not being considered.

Among the commercial solutions are, on one hand, two-mirror systems that use orthogonal galvanometer mirrors. They incorporate highly optimized actuators and encoders that provide high acceleration and short settling times as well as high angular repeatability; these systems can support beam sizes from 5 to 30 mm. On the negative side is the bulky form factor, the higher reflection loss due to the second mirror reflection, and the lateral beam shift due to the distance between mirror surfaces and virtual rotation points.

Another category is beam-steering devices that use microelectromechanical systems (MEMS) and microelectronic fabrication methods to create highly miniaturized devices. These include silicon mirrors rotated in two axes using gimbal-less flexures3 and electrostatic or magnetic actuation.

A third category is voice-coil mirrors (VCMs), which work like a loudspeaker. However, unlike a speaker, VCMs are often configured with a moving magnet instead of a moving coil. This arrangement has several advantages. The first is that since the coil is stationary, the wires do not have to move, which adds greater overall reliability. The second advantage is that the heat generated by the mirror coils is conducted to the mirror housing away from the optical mirror substrate; this prevents thermal distortions of the mirror wavefront quality.4, 5

Differentiators

There are several challenges that need to be overcome in traditional beam steering. First, mirror size matters. In the case of steering focused laser beams, the mirror size limits the maximum laser power (optical damage threshold and eye-safety considerations) as well as the minimum spot size.

In the collection path of an instrument, the mirror size determines how much of the light gets collected and detected. This is, for example, the case for optical coherence tomography (OCT), Raman spectroscopy, optical free-space communications, and lidar. For the last-mentioned applications, an additional important factor is the mechanical scan angle. In the case of MEMS mirrors, most of the time there is a tradeoff between mirror size, scan angle, and reliability.

Integration into OEM equipment requires compactness and easy hardware/software control. Voice-coil mirrors require low driving voltages and can be controlled from readily available programmable current sources.

For applications in harsh environments, resistance to mechanical shock and vibration is of key importance. Galvanometers, for example, with their large moving mass and long lever are not very suitable for such environments by design.

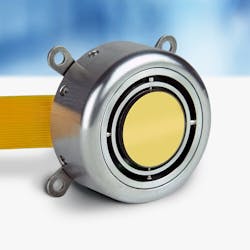

In 2017, Optotune introduced the MR-15-30 beam-steering mirror based on voice-coil technology. An exceptionally large aperture combined with a large range of accessible angles have led to the device being included in a wide array of products. Applications include machine vision, cosmetic lasers, lidar, OCT, and laser processing.

The MR-15-30 mirror has tilt in two dimensions with a range of 25° mechanical half angle around a single point of rotation. The mirror can be closed-loop controlled and can be operated in quasi-static mode as well as in scanning mode, including vector patterns. Direct access to the analog signals of the built-in position feedback system allows achieving position resolutions better than 5 μrad. The mirror has an integrated temperature sensor for thermal compensation as well as an EEPROM containing the angular calibration data. The center of moving mass of the MR-15-30 is at the center of rotation, making it very shock-resistant. A dual-axis VCM with position feedback is shown in Figure 1.

The MR-15-30 mirror is available currently with protected gold and protected silver coatings and soon with a UV-enhanced aluminum coating. Dielectric coatings are available as customization. The flexible coating choice is another advantage of this technology compared to many MEMS mirrors.

On the electronics side, Optotune has released a development kit with the mirror integrated into a dedicated driver platform, the MR-E-2 (see Fig. 2). The chosen Optotune MR-mirror is integrated into the head unit of the driver, together with analog driving electronics (proxy-board). A cable connects head and base units, with the base unit containing the digital control electronics (CPU-board) connected to the carrier board via edge connector.The kit allows quick testing of the mirror in the application using different interfaces (USB, UART, SPI, or analog voltage) and different software libraries (Python SDK, C# SDK). It also can be controlled by a graphical user interface (Opto Cockpit).

After successfully testing driver and mirror in the application, the user has the option to obtain the driver as an OEM version for different levels of integration into existing system electronics. The first level comprises CPU and proxy boards (two small boards not larger than the footprint of the mirror) as well as the reference design for straightforward integration of the driver in the overall client system. At this level, the driver acts as a slave, receiving commands via SPI from the system controller, with all control processes handled by the driver. For customers wishing to implement their own digital control, Optotune offers the proxy-board individually, leaving mirror control to the system controller.

Benchmarking

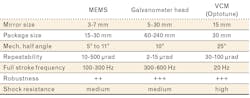

An overview of readily available 2D beam-steering technologies is shown in the table. In all three categories, resonant scan axes with higher frequencies are available in addition to a quasi-static axis. For example, Optotune offers prototypes of the MR-10-30, a 10 mm version of the mirror with one resonant axis at around 260 Hz in addition to a quasi-static axis, which is particularly relevant for raster-scan applications such as lidar.This article only considers nonresonant beam-steering technologies that are suitable for vector scanning and point-and-shoot applications. The mirror presented in this article belongs to the last category. Its focus is on very large tilt angles in 2D, high reliability to shock and vibration by design, and compactness.

Any of the three mirror technologies mentioned has its advantages and disadvantages; the particular application needs to define which technology is most suitable.

Applications

For users of Optotune’s MR products, three areas have generated disproportionate interest: lidar, field-of-view (FOV) expansion, and laser beam steering. In the wake of autonomous driving advances, lidar has become a focus of automotive manufacturers and suppliers. Various techniques such as conventional time-of-flight or frequency modulated sensors are now available. However, the performance of beam-steering approaches has not developed with the same pace. Most solutions as of now are either rotating mechanical or MEMS devices; these typically suffer from tradeoffs regarding the four primary parameters—namely price, speed, clear aperture, and FOV.

The beam-steering devices developed by Optotune have high performance in all four, enabling developers to quickly create working prototypes of lidars integrated into cars. Figure 3 shows a lidar system from SiLC Technologies integrated into a car’s headlight from Varroc Lighting Systems with two MR-15-30 mirrors providing a full 20° × 80° FOV per headlamp. In this case, a coherent frequency-modulated continuous-wave (FMCW) technique was used; the MR-15 30 was selected for its compactness, large mirror size, and large FOV. However, the MR-15-30 can be applied to any scanning-type lidar.Such an approach can be applied directly to surveillance applications and homeland security in airports and other busy public spaces. A possible configuration is depicted in Figure 4. The standalone camera on the right is equipped with a wide-angle objective to capture the overall scene. The camera on the left, equipped with a narrow-angle telephoto lens, looks at the mirror and can “zoom-in” and select a small AOI of about 5° out of a 100° optical FOV. Applications lie in security applications such as surveillance and face-tracking in airports and other public spaces.

REFERENCES

1. Y. Wang et al., Optica, 6, 5, 557–562 (2019).

2. See http://bit.ly/Optotune-Ref2.

3. See http://bit.ly/Optotune-Ref3.

4. See http://bit.ly/Optotune-Ref4.

5. See http://bit.ly/Optotune-Ref5.

About the Author

David Leuenberger

Senior Business Development Manager, Optotune

David Leuenberger is Senior Business Development Manager at Optotune (Dietikon, Switzerland).