Vibration Control: Effective vibration control expands spatial resolution boundaries

SYLVIA TAN

Technological advances enable observation, manipulation, and fabrication of extremely detailed objects. Examples of those objects and sizes range from nanometer-scale optical waveguide structures to living cells and protein-molecule scaffolds. Research and technology at such miniature scales require advances in precision and tolerance for the entire system design, including vibration control platforms.

Three challenging applications that require ultrahigh spatial resolution during manufacture and test—silicon photonics, micromachining, and super-resolution microscopy—demand vibration control platforms designed to eliminate vibrations that can disturb the end product or process.

Silicon photonics: pneumatic and tuned damping

Silicon photonics is the study and application of photonic systems that use silicon (Si) as an optical platform. Different from the traditional photonics setup, silicon photonics components are heavily integrated and miniaturized, as they are manufactured on a chip with nanometer-scale resolution. Devices such as optical connectors, ring resonators, filters, and modulators are manufactured using various kinds of high-resolution lithography methods, and are subsequently tested and characterized under tight mechanical tolerances.

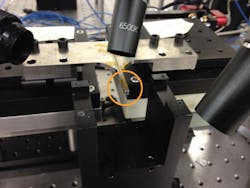

Compared to other types of optical characterizations, test fixtures and light sources are often not located on the same chip. This means that light needs to be guided to and from the chip precisely and without disturbances so that chip functionality can be properly tested. Given the ultracompact nature of the waveguides and other devices fabricated on the chip, fiber coupling is necessary to maintain tight spatial resolution.

"Vibration control is very important to us," says Rich Grzybowski, director of R&D Integrated Photonic Solutions at MACOM (Lowell, MA), one of the leading providers of silicon photonic chip designs and solutions. "When the resolution is down to around 100 nm, there are a lot of vibration sources around to affect the testing procedure."

Some of MACOM's test structures involve surface-normal optical coupling with fiber arrays into grating couplers. In this setting, the resolution and vibration control requirements are not critical because there is typically 1 μm spatial tolerance.

In other applications, MACOM uses edge couplers with various tapers and fibers coupled on the edge of a chip. This edge coupling reduces the tolerance by a factor of 10 to about 100 nm. For this aspect of testing, reducing micro vibrations from the floor, the stack of equipment on the test bench, people walking by or even talking—in close proximity to the test array—becomes extremely important to be able to maintain overall coupling efficiency (see Fig. 1).

For this application, the MACOM team uses Newport S-2000A pneumatic isolators (vibration isolators that require air or gas under pressure) and tuned-mass-damped ST-UT2 tabletops.

Pneumatic isolators such as Newport's S-2000A have large chamber volumes and accurate (0.25 mm) auto re-leveling capabilities to isolate floor vibrations. At 10 Hz, approximately 99% of the vibrations from the floor are eliminated.

Alternative choices of traditional rubber/elastomeric isolators and mechanical spring isolators cannot provide enough vibration isolation efficiency to obtain the spatial resolution needed for this type of coupling application.

Rubber/elastomeric isolators use the material itself as vibration absorbers and usually start isolating after 25 Hz, compared to 2 Hz for pneumatic isolators. The amount of vibration reduction from tuber/elastomeric isolators is typically not enough for sub-micron positioning requirements.

Spring vibration isolators are widely used in machinery applications to reduce transmission of noise, shock, and vibration. The isolation can start as low as 8 Hz through special design, such as Newport's VIBe isolators. However, compared to pneumatic isolators that work well for low-frequency vibrations caused by surrounding traffic and swaying buildings, VIBe mechanical isolators do not isolate below 8 Hz and are typically not sufficient to maintain the spatial resolution needed for silicon photonics applications.

For the tabletop, a very rigid and precision tuned-mass-damped optical table is used to prevent laser beam misalignment caused by tabletop vibrations. Tuned mass damping (TMD) is the most effective passive damping method, as it concentrates damping at the frequencies of the dominant resonance modes.

Newport's TMD technology (U.S. patent 8857585) eliminates the use of oil and instead uses a proprietary mass-spring mechanism that results in better damping performance and more precise and easier frequency tunings. Compared to alternative broadband damping methods, TMD improves the damping performance by 10X or more. Broadband-damped tables absorb and dissipate a moderate amount of vibration energies across a wide frequency range, but because they do not target any specific table resonances, they are typically not adequate for applications that require stability <1 μm. These TMD tables enable MACOM to configure optical test benches needed to develop and test their PIC and L-PIC brand photonic integrated circuit (PIC) products.

Microfabrication: pneumatic and active damping

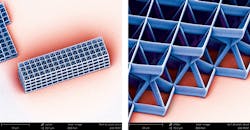

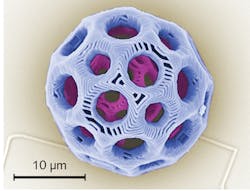

Another application pushing the resolution boundaries is microfabrication/micromachining by direct laser writing. Enabled by development of ultrafast laser systems, high-resolution, three-dimensional (3D) microfabrication techniques are flourishing and creating even more compact devices.At Newport's Technology and Application Center (TAC), scientists use two-photon polymerization (TPP) to fabricate 3D structures with no topological constraints at feature sizes around 100 nm. Vibration control is essential for this type of application because the 3D fabrication process requires ultrahigh levels of stability and precision (see Fig. 2).

"An essential part of the overall system stability is the vibration control platform," says TAC staff scientist Tommaso Baldacchini. "Controlling the vibrations during the fabrication process helps to achieve clearly defined edges and super-fine structures." When using high-numerical-aperture objective lenses to focus the laser beam in the photosensitive material and working with laser intensities just above the intensity threshold for polymerization, TPP voxels—3D volumetric pixels—with radial dimensions of 100 nm can easily be formed. Complex 3D microstructures are created by carefully overlapping these voxels to form a continuous polymeric network capable of sustaining itself (see Fig. 3).The writing that permits the overlap of polymerized voxels in a predetermined manner is accomplished using either computer-controlled stages or a set of galvanometric mirrors. In each case, vibration control is essential to ensure the level of accuracy required by the TPP process. This is particularly true in the case where TPP is used to generate micro-optical components, because surface roughness and material density homogeneity must be precisely controlled.

Here, pneumatic supports and an actively damped Newport SmartTable are essential to creating complex miniature structures. SmartTable optical tables use vibration sensors to sense tabletop vibrations and then in real time damp those vibrations using internal actuators. Compared to passively damped tables (broadband damped and tuned damped tables), the actively damped tables provide faster response and more precise real-time compensation across a wider frequency range from 40 to 550 Hz.

Active damping is more powerful than passive damping, as it reduces every single resonance peak within a broad frequency range. For laser direct writing with ultrafine resolution motion stages, SmartTable has faster settling time and more-effective damping performance. The system also performs automatic one-button adaptive tuning to find and cancel resonance peaks for a given payload distribution, and provides tabletop frequency monitoring and vibration data streaming and collection capabilities.

Super-resolution microscopy: active isolation

In 1873, Ernst Abbe derived a formula describing how optical diffraction limits the resolution of optical microscopes. This limitation stood for almost a century before some innovative scientists began to examine how to circumvent this physical barrier to achieve higher resolutions.

In 2014, the Nobel Prize in Chemistry was awarded to Eric Betzig, Stefan W. Hell, and William Moerner for having bypassed the diffraction limit. Because of their achievements, the optical microscope can now peer into the nano-world with even higher resolution.

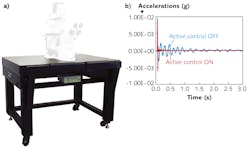

Vibration isolation and damping are critical to nanometer-scale microscopy. Common vibration sources for an imaging system include mechanical sources and acoustic sources. Specifically, central heating and cooling units (HVAC systems), low-temperature incubators, centrifuges, people talking and walking nearby, the sway of the building, and nearby street traffic are frequently observed as detrimental vibration sources (see Fig. 4). Many of these sources may not be present in the same room with the experiment, and are therefore hard to detect and remove.Compared with pneumatic isolation methods, active isolation senses vibration in multiple degrees of freedom in real time, and instantly counteracts those vibrations using electromagnetic or piezo actuators to isolate vibrations from the environment as low as 0.5 Hz. An active isolation system such as Newport's new Guardian workstation starts isolating vibrations from around 0.5 Hz, and maintains very high isolation efficiency in all six degrees of freedom.

Built upon VIBe isolators, the active modules in Guardian reduce vibrations by 10X at 1.5 Hz. The system uses high-precision, low-noise electromagnetic vibration sensors (sensitive from as low as 0.1 Hz) and passes the electrical signals to a sub-hertz, ultralow-noise control system that applies advanced filtering and conditioning to the signals. The processed signals are then sent to the actuators to compensate for the vibration at a servo rate as high as 10 kHz.Active vibration isolation has helped to greatly reduce the vibrations reaching the tabletop, creating an ultra-stable foundation to render super-resolution images (see Fig. 5). Combined with advanced damping technology integrated in the work surface, workstations like this will serve as fundamental building blocks that enable the future of even higher-resolution applications.

REFERENCE

1. J. Fisher, "Is vibration control really necessary for microscopy," BioPhotonics (Jul/Aug. 2010).

Sylvia Tan is product marketing manager for vibration control at Newport Corporation, Irvine, CA; e-mail: [email protected]; www.newport.com.