VIBRATION CONTROL & SYSTEMS: Vibration isolation choices influence application outcomes

RAMKUMAR KRISHNAN

Technological advances—in both materials and processes—are expanding the use of powerful optoelectronic devices beyond traditional laboratory settings and into manufacturing. These highly sensitive instruments are now being used in nanotechnology, microcircuitry, micromachining, and miniature robotics for testing and quality assurance/quality control. And with their proliferation comes an increasing need for vibration isolation equipment to improve accuracy and productivity. Today's market offers a confusing array of such products; but with so many choices, it is important to match the equipment to the application (see Fig. 1).

Everything vibrates

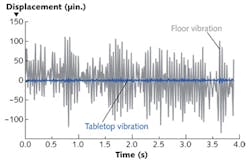

Because of traffic, machinery, HVAC systems, elevators, weather, and natural frequencies, everything vibrates (see Fig. 2). In high-precision applications, vibrations need not be obvious to cause excessive signal noise, low-frequency jitter, and high-resolution image blur. In fact, uncontrolled vibrations can even cause excessive wear and structural damage to electromechanical and optical equipment.In general, the more precise the work, the more vibration control is required. In most cases, the cost of such equipment is far less than that of stalled production or equipment and experiments flawed by unwanted vibrations.

The two most important factors to consider in choosing vibration-isolation equipment are natural frequency and isolation efficiency. The best systems achieve very low natural frequencies and attenuate all potentially damaging vibration amplitudes in the 8 to 200 Hz broadband random-vibration spectrum. Very low stiffness is needed to obtain desired low natural frequency and thus high vertical and horizontal isolation efficiency. With so many variables to consider, it makes sense to have an expert conduct an on-site vibration survey and recommend the most appropriate vibration-isolation equipment for your location and requirements (see Fig. 3).Although they need to be supported by low-frequency support systems, tabletops should have high natural internal frequencies. Tabletops can be constructed of aluminum, steel, or corrosion-resistant materials such as lightweight plastics or layered composites with antistatic or stainless-steel laminates, but ones built with honeycomb cores of hexagonal cells offer lighter weight, more rigidity, and natural frequencies higher than those attainable with ribbed cast iron or solid granite block of the same size. Many have a spillproof section under the top layer to channel spilled liquids away from the core, where they can be drained. For vacuum applications, tabletops should be built with low-outgassing epoxies.

Modern vibration control solutions range from simple mounts and breadboards to highly efficient air systems, active electronic systems, and negative-stiffness systems. Many incorporate the latest advances in composites and adhesives, corrosion-resistant metals, and layering techniques.

Passive air systems rely on air bladders that are replenished by hand-pumped or compressed air. Passive air isolators offer high-frequency vibration isolation in less critical applications where low-frequency vibrations below 10 Hz are unlikely. They require manual leveling and damp vibrations above a preset system frequency.

Active air systems that are self-leveling use servo valves that automatically fill or bleed isolators to eliminate deflection and keep the tabletop level as the load varies or moves. Vibration isolation efficiencies approach 99% for vertical (70-75% of the vibrations in an average building) and 95% for horizontal.

Some active air systems use frictionless, rolling-diaphragm air seals in conjunction with dual air chambers. Their stiffness is a function of the combined air volume of the dual chambers. Some systems add pistons that enhance horizontal isolation.

Active air workstations provide stability for balances; confocal, tunneling, atomic force, or optical microscopes; roundness checkers; surface profilometers; and other equipment used in cell injection, patch clamping, testing, inspections, wafer probing, and mask aligning in industries such as medical research, semiconductor processing, telecommunications, and aerospace engineering.

Specialized active air equipment is used in a variety of workstations, benchtop platforms, and mounts, in a variety of configurations. Small, personal workstations provide economical vibration isolation in small labs and other tight spaces. High-performance workstations can be easily customized with accessories; high-capacity workstations can handle heavy, tall, or moving loads; dual-stiffness workstations have mounts that "harden" to prevent tilting when a load is moving, but "soften" once the load is in position, for precise vibration isolation. Variable-height workstations have quiet, electrohydraulic mechanisms that allow users to smoothly raise or lower the tabletop to reduce fatigue and back stress; and active air benchtop platforms provide vibration isolation without the need for a permanent, dedicated table, with horizontal and/or vertical vibration control.

Mounts and legstands using passive and/or active air technology are ideal for large equipment weighing up to 20,000 lb. Vibration-isolating legstands with internal trifilar and quadfilar pendulum systems have natural frequencies close to 0.9 Hz, providing exceptional horizontal vibration isolation. And, combined with active air suspension, they offer the highest protection against vertical vibrations as well.

Legstands can provide automatic leveling of breadboards and optical tables, and are available as modular mounts or with braces and casters. With low natural frequencies, they can achieve isolation efficiencies of 98% (horizontal) and 95% (vertical) at 10 Hz and above.

Pendulum suspension base platforms are designed to provide vibration isolation for tall equipment that needs to be close to floor level, and have an exceptionally low (0.75 Hz) horizontal natural frequency to enhance the performance of sensitive equipment such as nuclear magnetic resonance spectrometers.

Raised-floor "islands"—an alternative to pendulum suspension base platforms and poured-in-place isolation pads—are primarily used in cleanrooms where a false floor could not support the weight of large equipment and a vibration isolation platform (see Fig. 4).Active electronic systems use microprocessors to generate "active feedback": immediate responses that eliminate any sensed vibrations. Rapidly and automatically adjusting to moving loads or loads with high centers of gravity, this type of system dynamically isolates all six translational and rotational modes of vibration. Active electronic benchtop platforms provide portable vibration isolation for interferometers, scanning-probe microscopy stations, and imaging microscopes.

Negative-stiffness equipment provides ultralow natural frequencies, high internal structural frequencies, and excellent vertical and horizontal isolation efficiencies for static loads. Beam columns connected in series with a vertical-motion isolator provide horizontal isolation. Ideal for microscopes in semiconductor processing, aerospace engineering, medical research, and other fields, negative-stiffness vibration isolation workstations achieve superb vibration isolation efficiencies (to 99.7% at 10 Hz).

Optical tables are ideal for ultrasensitive optical equipment when they incorporate either passive- or active-air isolation legs. They provide very high isolation capabilities at very low frequencies (2 Hz and lower), with quick response to micro disturbances.

High-quality optical tables offer quad-tuned as well as broadband vibration damping using individual absorbers (tuned to the bending and torsion frequencies of each table). This narrowband selective damping is provided by frequency-tuned, mass-spring resonators (embedded in all four corners of the table), dry damped and tuned to resonate 180° out of phase with the lowest natural frequency of the table. The out-of-phase inertial forces absorb or cancel the motion of the table at its natural frequency and reduce resonant amplification. Aluminum barriers added between the top skin and core can make these tables truly nonmagnetic.

Vibration equipment for cleanrooms

In a cleanroom environment, vibration isolation equipment should minimize the amount of horizontal surface and be impervious to liquids for easy cleaning. Completely enclosed isolation modules and vented exhaust systems are also available, and Class 1 equipment is often manufactured from stainless steel with an electropolish finish. Most vibration isolation equipment is Class 100 compatible, but for Class 10 compatibility, manufacturers produce models with clear passivate finishes. Designed to house a workstation, optical table, or other equipment, mobile cleanrooms are portable environmental enclosures with side curtains for dust-free assembly, testing, and research.

Accessories and accuracy

Shelves, drawers, laser ports, electrical outlets, monitor supports, lighting, guardrails, padded armrests, retractable casters, and other accessories add convenience to vibration isolation workstations or optical tables. Faraday cages protect against electromagnetic interference; other tabletop enclosures create environmentally controlled spaces within harsh manufacturing environments, such as "darkbox" enclosures for optics production, testing, or research that block all ambient light. These darkboxes can be portable yet large enough to incorporate optical tables or workstations. Along with sliding or fixed side panels, they can also be fitted with a dizzying array of accessories.

Contrary to some manufacturer claims, vibration isolation equipment performs at different efficiencies depending on payload. For the best performance, typical payload should weigh no more than 80% of the equipment's rated load capacity. For a workstation or support system, look for manufacturers that offer equipment in more than one load range. Some manufacturers also offer modular support systems for retrofitting workstations or optical tables to increase or decrease load capacity in the quest for greater accuracy.

Vibration isolation accuracy is often related to ergonomics. There is no point in eliminating blur and jitter from microscope work, for example, if the operator cannot stay comfortable and alert. With good design and wise use of materials, vibration isolation equipment can be user-friendly.

While the demanding manufacturing and research and development environment of the future will likely pose new vibration isolation challenges, ongoing research and product development offer hope that we will be able to meet these new challenges as they arise.

Ramkumar Krishnan is research and development manager for Kinetic Systems, 20 Arboretum Rd., Boston, MA 02131; e-mail: [email protected]; www.kineticsystems.com.