MOTION CONTROL: UHV environments require more from motion systems

MILAN ZEMAN and JAY TITUS

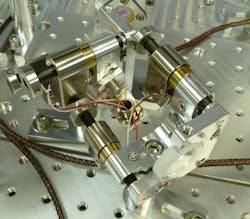

Applications that require UHV environments [defined as a pressure of 10-7 pascals (10-9 torr) or less] are now found in a range of research and manufacturing applications. High-energy particle accelerators, laser-based gravity wave detectors, and systems for precise thin-film deposition are just some examples where reliably operating in the UHV regime is essential (see Fig. 1).

Other applications including atomic and ion trapping and Bose-Einstein condensate research require vacuum systems that can pump down quickly and maintain extremely low pressure for long periods. In addition, many applications utilizing high-power or deep-ultraviolet (DUV) lasers require motion components with extremely low levels of volatile materials to prevent contamination that could corrupt samples or substantially reduced the damage threshold of sensitive optics, detectors, and sources.

This paper presents work we have recently completed on motion systems for these environments and will review critical design features, appropriate selection and preparation of materials, and qualification testing methods. Comparison test results for both standard and UHV qualified devices and new directions we are taking to improve the vacuum performance further are also presented.

UHV motion system design

Ultrahigh-vacuum applications have resulted in a growing need for motion mechanics for the manipulation and control of optics, particle beams, and measurement devices inside UHV chambers. These actuators must offer the ability to be remotely controlled with a high degree of accuracy. Moreover, they must be designed and manufactured to have very low outgassing to prevent any contamination of the vacuum system.

Further complicating both design and materials selection, these actuators often need to go through an in situ high-temperature bake-out process to remove absorbed water from the vacuum chamber. Finally, the design of components and enclosures must be carefully considered in order to eliminate air entrapment (virtual leaks) and particulate generation.

Actuators such as the New Focus Picomotor were originally designed for use in normal laboratory environments; however, in response to customer needs for a high-precision actuator that could be used in UHV environments, significant redesign was required. The materials and methods we discuss here were key to the successful modification of a standard actuator into one modified for the UHV environment, in this case the UHV Picomotor.

To modify the original actuator design, all aspects of mechanical design, selection, and fabrication of materials, cleaning, and assembly procedures had to be carefully evaluated and controlled. Actuators offer the added challenge that lubrication is almost always needed to reduce wear and the associated particulate generation.

The first step in preparing any mechanical device for use in a vacuum system is to review the design to identify and redesign all parts containing blind holes and volumes that can entrap air. For example, in our actuator a ball tip is press-fit into the end of the actuator screw. Press-fitting eliminates the need for epoxy (a potential source of volatiles), but it could result in a virtual leak if air becomes entrapped between the ball and screw.

By replacing the solid screw with a chemically cleaned and vented actuator screw, any entrapped air can be quickly evacuated. All mechanical interfaces and enclosures must either be completely sealed and leak tested, or a path provided to ensure that air and other volatiles quickly escape during pump down.

Next, all materials—including adhesives, primers, lubricants, fluxes, and insulation—must be reviewed for levels and chemical makeup of volatiles. If custom metal work is part of the design, then manufacturing materials such as cutting fluids and lubricants used by the supplier need to be considered so residue is kept to a minimum and any material that remains can be readily removed during cleaning. For example, aqueous-based cutting fluids are usually specified for components intended for high-vacuum or other contamination-sensitive applications.

Another common source of contamination is improperly cured epoxies and other adhesives. Curing temperatures and procedures for all adhesives need to be understood and clear work instructions provided to ensure that only vacuum-qualified materials are used. Information regarding cure times and volatiles is usually available from the manufacturer. In critical applications we have found it worthwhile (and often required by the customer) to do our own qualification since subtleties such as age, storage conditions, and humidity can impact cure rates.

Typically "buttons" made from the material under test are cured under various conditions. The samples of each material are then placed in a vacuum chamber and RGA [residual gas analyzer] used to identify and measure the partial pressure levels of volatiles.

When selecting materials for a UHV actuator, one of the most critical is the lubricant. To ensure long-term reliability and consistent performance, a very precise amount of lubricant must be applied to the 80-pitch screw used in our actuator. The lubricant must be low viscosity so a uniform coating can be applied without damaging the threads, yet have high enough viscosity to minimize flow to adjoining areas.

Many high-vacuum equipment manufacturers require proprietary lubricants; however, many of these have proven to be incompatible with Picomotor requirements. We have identified a family of PEPE/PTFE lubricants that offer the viscosity, lubricity, and low outgassing required, but even within this family, volatility and chemical stability can be quite different from one formulation to the next.

Last, the actuators must be cleaned, assembled, and packaged under conditions and protocols that are consistent with the requirements of the target markets. For example, our standard Picomotors, which are intended for general laboratory applications, are built under Class 10,000 protocols. The UHV version is used in semiconductor capital equipment and medical markets, and consequently is built in Class 100 workstations and double packaged. Material used for the inner package material is cleanroom certified so it can be opened in a highly controlled environment without requiring any additional processing or precautions by the customer.

UHV motion system qualification

When testing materials for vacuum applications, two important characteristics need to be measured. The first is outgassing kinetics, which determines how efficiently the required vacuum level can be maintained and also helps to identify effective bake-out times and temperatures. Understanding bake-out kinetics is especially important when the maximum temperature is limited by potential damage to the actuator.

The second measurement determines the type and abundance of species released. Although a number of screening methods are used by the aerospace and microelectronics industries, we have elected to use thermal desorption gas chromatography mass spectrometry (TD-GC-MS) for species identification and ASTM E1559 to measure the time- and temperature-dependent kinetics.

The ASTM test is an isothermal outgassing test where the material under test is placed in a temperature-controlled effusion cell inside a vacuum chamber. The material in the cell is then heated and held at a constant temperature for 24 hr and the volatile materials collected by several temperature-controlled quart crystal microbalances (QCMs). A liquid nitrogen shroud surrounds the test cell and the QCMs to ensure the molecular flux impinging on the QCMs is due only to the sample in the effusion cell.

A typical arrangement is shown in Fig. 2. For our testing, the vacuum chamber is held at 10-9 torr and the effusion cell typically at 55°C. One QCM is maintained at 80 K throughout the test to measure total mass loss (TML) and outgassing rate as a function of time. The other QCMs are held at 160 K, 220 K, and 268 K. At the end of the test, a thermo-gravimetric analysis is performed on the species that have condensed on the QCMs. A mass spectrometer built into the test chamber provides a detailed identification of the outgassed materials. The same methodology and sampling techniques are used for both the UHV Picomotor and the standard Picomotor.The TD-GC-MS test involves subjecting the sample under test to an elevated temperature for a period of time to drive volatile compounds from the sample. For our tests, the actuator is heated to 55°C and sampled for 2 hr. While the material is held at a steady, elevated temperature, a flowing gas sweeps volatilized material into an adsorbent trap, such as activated charcoal.

After a predefined period, the trap is heated and the thermally desorbed materials swept into a gas chromatograph and identified using mass spectrometry. While this method does not provide kinetic data, it is quick (typically 2 to 3 hr) and provides detailed identification of volatiles species with sensitivity to parts per trillion.

Test results

A summary of the ASTM 1559E test results for both the UHV Picomotor actuator and the standard (non-UHV) Picomotor is shown in Table 1. The different species are separated into categories according to their relative volatilities as determined from the QCMs that are held at warmer temperatures.Plots of ASTM 1559 E test data in Figs. 3 and 4 show a significant reduction in TML for the UHV Picomotor, compared to our non-UHV product. Levels of low and medium boilers are not only significantly lower for the UHV actuator, but the rate of outgassing quickly asymptotes.

Future directions

As specifications for UHV systems continue to become more demanding, customers will require actuators with ever-lower levels of volatiles and better particulate control without sacrificing reliability. Additional high-temperature bake-out studies are now in progress with our current products to determine the most effective means to quickly remove volatiles.New lubricants, surface finishes, and cleaning techniques are being evaluated to further reduce TML. The most demanding applications involving extreme-UV (EUV) lasers and high radiation may require actuators that are completely sealed in 100% leak-tested enclosures with vacuum feedthroughs for power.

ACKNOWLEDGMENT

Picomotor is a trademark of Newport Corp.

Milan Zeman is senior product marketing manager at New Focus, 3635 Peterson Way, Santa Clara, CA 95054; e-mail: [email protected]. Jay Titus is senior manager, reliability engineering at Spectra Physics; e-mail: [email protected]; www.newport.com.