Vibration Control: Electro-pneumatics isolate vibration for shock-sensitive machines

JAN HANSEN-SCHMIDT and WILLIAM GRANCHI

Depending on the requirements regarding precision and accuracy, vibrations can degrade the results of a production or measurement process. As precision requirements increase, vibration control systems must likewise increase in efficiency. Electro-pneumatic position control provides efficient vibration isolation for highly dynamic and shock-sensitive machines operating in a variety of industries.

Electro-pneumatic position control

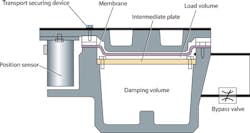

The electro-pneumatic position control (EPPC) system launched by Bilz Vibration Technology in the fall of 2013 uses low natural frequency membrane air spring isolators that can be mounted directly below machine supports or a support platform. As a real-time level-control system, its two-chamber membrane air-spring system design consists of a load and a damping volume (see Fig. 1). Both volumes are connected by an adjustable mechanical bypass valve. Any deflection of the isolated machine on top of the element leads to a change in the size of the load volume and a resulting air flow from one air volume to the other through the bypass.

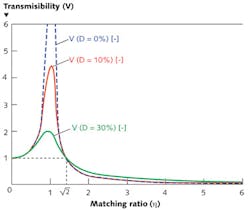

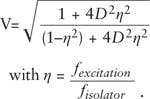

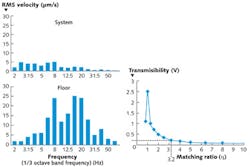

Due to air friction inside the bypass, energy will be converted into heat; damping (D) up to a maximum value of 20% can be created. The natural frequency of the given air springs ranges between ~1.1 and 2.5 Hz in the vertical direction, whereas the horizontal direction is characterized at around 2.5 Hz.If the damping factor D is taken into account, efficiency of any vibration isolation system depends significantly on the matching ratio η between excitation frequency and natural frequency of the isolator (see Fig. 2).1 In general, the efficiency of vibration isolation increases as the natural frequency of the isolator drops according to the following equation:

In general, systems provide vibration isolation when the matching ratio η exceeds √2. If the ratio is less than √2, the vibration will be amplified due to resonance effects. Typically, the objective is to achieve a ratio of between 3 and 4, wherein a ratio of 3 is considered to be the minimum effective target value (isolation efficiency of nearly 80% can be achieved) and a ratio of 4 is an economic limit.2

Floating on air

Air-spring technology has numerous advantages compared to steel springs, electromagnetic actuators, or linear motors. Due to the linear correlation between air pressure and load capacity, air springs are highly flexible and easily adaptable to different load distributions. In practice, the typical air pressure applied inside the air-spring element is between 4 and 6 bar, which results in a total load capacity of up to 15.5 tons per element.

The mechanical properties of air springs (stiffness and natural frequency) are nearly constant within a reasonable range of operation. Also, they provide very high mechanical stability and do not require any additional damping elements. Furthermore, very low energy consumption leads to minimized heat generation and magnetic variation.

For a given application, an EPPC leveling system requires several components (see Fig. 3). In addition to the air-spring elements, a control unit with different state indicators for the operator (system status, error flag, and motion complete signal) can be connected via a standard Ethernet connection for system configuration, supervision, and system monitoring.An air-maintenance unit provides air-pressure monitoring via electronic pressure switch, a shut-off valve for system pressure control, regulation and adjustment of system air pressure, a filter combination for compressed air conditioning (5 μm and 1 μm, required air quality according to ISO 8573-1:2010 class 2.3.2), and collected exhaust air for controlled discharge including noise reduction through a sound absorber.

High-precision servo-valves contain 16 bit digital signal processors running with 60 MHz, integrated level control via PID controller, 14 bit resolution analog-to-digital (A/D) converter with a resolution of 0.76 μm (position) and 0.36 mbar (pressure), CAN-Bus connection (1 Mbaud), and a maximum working frequency of 300 Hz. Finally, electronic level sensors (potentiometers) offer 1000 digits per 12 mm.

Application-specific configurations

Optimized for vibration isolation of microscopes in optoelectronic applications as well as for test equipment and production machines in the semiconductor industry, EPPC technology can be combined with three or six groups of air springs to control up to six degrees-of-freedom. Multiple air-spring types and sizes are available to ensure that design and layout of the isolation system perfectly matches the individual demands of the specific application.

The Bilz EPPC level control enables control and monitoring of the machine position for every degree of freedom as well as internal air pressure of the air springs to control the dynamic behavior of the system. The performance of the passive air spring itself is significantly improved by using a high-performance A/D converter and 16 bit processor that allows nearly noise-free regulation.

Servo valves mounted very close to the air springs eliminate control degradation through pressure losses in the air tubes. The use of air-spring technology avoids any disturbing heat generation, magnetic variations, or high electrical power consumption as observed when using electromagnetic actuators and linear motors that require high currents to drive the actuators. In addition, the CAN-Bus topology allows a distance of up to 30 m from the isolation system to the electronic control unit itself. In this way, the isolation system can be applied even at highly sensitive locations and in surroundings such as in clean-room environments.

At load changes, EPPC provides ±8 μm level accuracy over a 12 mm range. This is especially important for high-precision machines that require little deflection as well as short settling times, which is required by a process to reach and stay within a certain range of position.

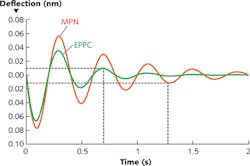

Compared to conventional mechanical-pneumatic position-control systems, EPPC significantly reduces settling time due to air-spring damping (see Fig. 4). Applying an excitation amplitude of 80 μm, the mechanical pneumatic system (D = 10%) reaches a stable position within a range of ±10 μm after ~1.5 s. For the EPPC system (D = 30%), settling time reduces by 50% to a~0.75 s.For shock-sensitive equipment and applications, all EPPC-required controller parameters can be defined separately for each pneumatic valve to determine the dynamic (P value) and settling (I value) behavior as well as the dampening properties (D value) of the isolation system: the so-called PID controller parameters. By individual adjustment of the machine parameters to the dynamics of the specific application, a damping factor of ~30% can be achieved. This leads to a reduction of amplification in the resonance frequency range, a variable stiffness of the separate air-spring elements and, as previously mentioned, a severe reduction of the settling time.

Furthermore, the system monitors the supply of compressed air and electrical energy. In the case of an interruption of the air and energy supply, application-specific shut-down ramps can be defined to avoid any damage to sensitive machine components, equipment, and work pieces. Also, inflation and air-spring elements can be defined by the machine operator to ensure smooth activation and deactivation of the isolation system.

Quantifying performance

We have previously installed EPPC systems to accompany the assembly and calibration processes for optical camera elements in the automotive field with an aim to reduce floor vibrations in the optical monitoring and quality verification units. The checking process requires a steady image from the tested, previously assembled camera. For proper analysis of the test picture, it is important that the image exhibit minimal blur; in turn, this requires highly efficient isolation against floor vibrations created by surrounding machinery that consists of numerous camera assembly machines.For this camera application, the EPPC system isolates vibrations from 3.5 Hz and above. With η = 3.2 (which corresponds to an excitation frequency of 8 Hz), the EPPC system achieves a respectable efficiency of 80%-indicative of the capabilities of an optimized electro-pneumatic vibration isolation platform (see Fig. 5).

REFERENCES

1. P. Alabuzhev et al., Vibration Protecting and Measuring Systems With Quasi-Zero Stiffness, Taylor & Francis, Abingdon, England (1989).

2. J. Milberg et al., Dynamisches Verhalten von Werkzeugmaschinen, Institut für Werkzeugmaschinen und Betriebs wissenschaften IWB, München (1995).

Dr. Jan Hansen-Schmidt is sales manager at Bilz Vibration Technology AG, Böblinger Straße 25, D-71229 Leonberg, Germany. William Granchi P.E. is sales engineer at Bilz Vibration Technology Inc., P.O. Box 241305, Cleveland, OH 44124; email: [email protected]; www.bilz.ag/en.