PRODUCT FOCUS: OPTICAL TABLES: Optical-table basics: from breadboards to active vibration-control systems

A fundamental component of any optical experiment is a table system upon which to build it. A table system is a big-ticket item that can quickly spiral into a budget-busting headache if you don’t carefully weigh the options and specifications across a vast variety of available solutions. Following is some guidance from the experts to get you started.

The term optical-table system typically refers to a vibration-isolation system—the tabletop plus the support system (legs)–and such tables generally come in several grades, determined by the level of vibration damping they provide. Basic optical tables for general-purpose use are suitable for quiet environments and provide little or no vibration damping mechanisms, but because of their honeycomb composite construction they provide a rigid platform for general optical experiments that are relatively insensitive to vibration such as spectroscopy, velocimetry, and non-phase-dependent applications.

An intermediate-grade table typically incorporates broadband damping or a moderate level of tuned mass dampers to reduce the compliance of the table to disturbances. It is typically preferred for experiments like bioimaging, Raman spectroscopy, nanopositioning, and machining. For more demanding applications like interferometery, nanopositioning, and imaging, or for labs with excessive vibration and acoustic noise, users should consider a higher-performance table that provides the maximum damping and consequently the most quiet table surface for their application. Tables in this category incorporate more tuned mass dampers or active dampers (see Fig. 1).

First considerations

The two most critical aspects to consider when purchasing an optical table are your primary application and the lab environment, says Christian Johns, applications engineer at Thorlabs (Newton, NJ). Some projects are less demanding with respect to alignment, long-term stability, and vibration isolation/damping; others can be extremely susceptible to all of these issues. “It is important to know and understand the sensitivity of a customer’s work to properly recommend the appropriate platform,” says Johns. The sources of noise in the lab must also be considered.

James Fisher, group director of the Vibration Control Business Unit at Newport (Irvine, CA) agrees. “The first questions we ask are, ‘What type of lab do you have? Is it noisy or quiet? Is your lab isolated by quiet interior walls, or does it include exterior walls adjacent to a city street or highway? Does foot traffic during the day make the lab unusable?” Some manufacturers conduct a site survey to evaluate the noise in the room. A survey can ensure optimal performance without overspending. In general, an assessment of the lab vibration levels and review of the experiment requirements can help users save real money.

Tony Hallas, director of sales and marketing at Kinetic Systems (Boston, MA) says his number-one question for customers is how much weight will be on the tabletop? “The most common mistake that buyers make,” says Hallas, “is not understanding the weight they’ll put on the table. The wrong value adversely affects vibration-isolation performance.”

Isolation vs. damping

In optical tables, “noise” refers to three types of vibration: seismic, acoustic, and tabletop forces. Seismic vibrations come from the ground underneath the table and are caused by foot and vehicle traffic, wind, and building vibrations, for example. Acoustic noise comes from sound waves that travel through the air and walls. Tabletop forces are caused by vibrations on the working surface, such as a moving positioning stage or vacuum-system tubing.

If a lab is subject to seismic floor vibration, the primary concern is isolation, which is addressed by the table support system. Most optical-table manufacturers offer pneumatic isolation systems that begin isolating at around 1.3 Hz and effectively isolate up to 90% of the vibration energy starting at 5 Hz and above and most reach 99% efficiency at around 10 Hz.

Vibration isolation is a low-frequency problem, occurring at about 50 Hz and below, according to Steve Ryan, vice president of marketing at Technical Manufacturing (TMC; Peabody, MA). Vibrations generated on the table surface are high frequency (more than 50 Hz) and require damping, which is addressed at the tabletop level.

While the vibration-isolator system underneath a table is designed to filter floor vibration before it reaches the tabletop, it’s the table’s honeycomb structural rigidity and method of damping that protects against deflection from moving loads or any vibration that passes through the isolation system. Passive damping, either broadband or tuned, provides varying levels of structural damping performance but both are affected by varying tabletop loads. Actively damped tables incorporate sensors and electronics to both sense and actively damp tabletop vibrations and can be “auto-tuned” to account for varying table loads. These systems have also demonstrated the ability to reduce noise transmitted to optical components, making their benefit to optical experiments even greater. Typically, manufacturers of microscopes and other optical equipment specify the vibration isolation frequencies required from a table.

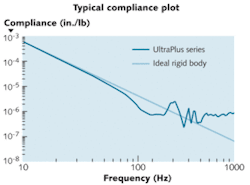

One key performance metric used to evaluate the performance of an optical table is the compliance curve of the table, an industry-standard measurement that charts the natural vibration modes of the table under a static load as a function of frequency (see Fig. 2). Compliance is defined as the deflection of the table divided by the pound-force (lb-force) applied at a certain point. If compliance curves are used to compare products, a buyer should first pinpoint the sources of noise in the lab environment so that the curves can be evaluated at the specific frequencies in question. “A high-end active-isolation system may provide the best overall damping available,” says Johns, “but for many applications, that’s like lighting a cigarette with a cruise missile. The advantage may be negligible at the specific frequency of your experiment.”Some makers use the compliance curve to derive other numbers, such as the dynamic deflection coefficient–an overall measure of a table’s motion when subject to vibrations. According to Fisher, in addition to the typical table specifications, which are derived estimates, users should also request actual test data from manufacturers to assist in the selection of the proper table for their application. Most experts agree, though, that more than one figure of merit should be considered when comparing products, especially if an experiment is sensitive to specific frequencies or conditions. The transmissibility curve, another figure of merit, tracks the efficiency of the vibration damping of a pneumatic isolator. Taken with the compliance curve, the two plots are a good way to compare the primary performance capabilities between systems.

Stiffness, or deflection under load, which is the reciprocal of compliance, is another useful specification. Stiffness of an optical table is measured by placing a load at the table center and measuring the deflection of the surface. Table isolators typically perform best under maximum load. To compare stiffness between manufacturers, buyers should consider the test conditions (the estimated load) in light of the maximum deflection results. Use the number that best matches the estimated load you will have on your table. Finally, a price comparison and evaluation of other features and accessories completes the selection process.

Acquisition and use

Newport’s Fisher describes the table-buying experience in three equally important steps: selection, acquisition, and use. Despite the effort invested in picking a table based on lab environment and performance specifications, be prepared–there’s much more to the process.

Acquisition involves shipping and receiving the table. The cost of shipping and delivery is not trivial. Breadboard tabletops may weigh 200 to 300 lb, while a large pneumatic tabletop can be upward of 2700 lb, plus another 400 lb for the support structure. And sometimes, says Fisher, buyers forget to consider whether their facility has an adequate loading dock, and if the chosen table can fit in the elevator, through the doors, and into the lab. Fisher recommends that buyers consult with their facilities departments to verify that the table can be received and moved safely into its final location. A forklift is typically required to unload the tabletop from the delivery truck. A crane may be required to deliver a two-ton steel table into the lab. And buyers may need to arrange for a professional equipment rigger to receive the equipment and deliver it to the lab (an additional expense).

Further advice: leave time for shipping to avoid exorbitant next-day delivery charges. Meet the table at the loading dock, and before you sign for it, inspect inside the box for damage during shipping.

The final step in the table-buying experience is set-up and use. For optimal operation, the table must be plumbed properly. Each supplier has different requirements for plumbing a vibration-isolation system, which should be provided with the table. Don’t make the mistake of skipping the manufacturer’s procedure manual before putting the table together. The manual walks you through the critical steps in order. And most important, make sure that your optical-table manufacturer also offers the support needed to help you sail through all points of the process.

Editor’s note: The “Product Focus” series is intended to provide a broad overview of the product types discussed. Laser Focus World does not endorse or recommend any of the products mentioned in this article.

Valerie Coffey-Rosich | Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.