OPTICAL GYROSCOPES: External-cavity semiconductor ring-laser gyro achieves single-mode operation

A team of scientists is the first to develop an external-cavity semiconductor ring-laser gyroscope that achieves single-mode operation.1 Previous designs based on coupling a semiconductor optical amplifier (SOA) to an external laser cavity achieved only low-performance multimode operation. The team includes scientists at Thales Research and Technology (Palaiseau, France), the Centre National de la Recherche Scientifique (CNRS) UPR 20 Laboratoire de Photonique et Nanostructures (Marcoussis, France), and the CNRS and Montpellier University Institut d’Electronique du Sud (Montpellier, France).

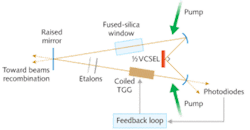

To achieve single-mode, high-performance rotation sensing, the researchers implemented a free-space cavity containing a quantum-well half-vertical-cavity semiconductor-emitting laser (1/2VCSEL) structure that acts as an active mirror. The “beat” signal that is proportional to the rotation rate of the gyroscope is obtained from the interference of two counterpropagating waves in the cavity (see figure). It turns out that coupling between the gain medium in a 1/2VCSEL and the external cavity is easier to achieve than in an SOA design because the pump area and the cavity mode are both circular and of a comparable diameter, creating a higher-finesse cavity due to reduced injection losses. In addition, there is a longer-term option for electrical pumping with a full VCSEL architecture, which would lead to an even more compact and lower-cost gyroscope.

Unfortunately, the grating structure defined by the planes within the 1/2VCSEL device makes the beat regime unstable and prone to phase locking of the two counterpropagating waves. To combat these drawbacks, a feedback loop is added into the setup that monitors the two signals and results in a stable beat regime, as previously demonstrated in the case of Nd:YAG ring lasers.2

Creating the beat signal

The 100-µm-diameter output from two 200 mW single-transverse-mode 808 nm laser diodes is first focused onto the 1/2VCSEL device. Polarizing effects within the cavity induce different losses for the two counterpropagating waves, which interfere in the external-cavity setup. Due to the mechanical vibrations of the laboratory experiment, two etalons are necessary to reinforce stable monomode operation. As with standard helium-neon ring-laser gyroscopes, the rotation rate is obtained from the beat-note signal frequency, whereas the rotation angle can be calculated by counting the interference fringes.

Beat-note signal analysis shows peak heights at about 30 dB above the noise level and a full-width-half-maximum of 200 Hz, limited by the measurement device and stable for a rotation rate above 20°/s. The beat signal disappears for a rotation rate below 15°/s because of backscattering from the optical elements within the cavity. This limit, however, is due to the experimental setup and could be lowered by replacing one of the standard cavity mirrors by a polarizing mirror and integrating a semiconductor Fabry-Perot filter on a second mirror. The beat-note signal width–much narrower than previously published multimode results obtained with SOA-based semiconductor ring-laser gyroscopes–opens the door to better rotation sensing. Moreover, nonlinear effects due to population-inversion gratings are strongly reduced by carrier diffusion in this semiconductor gain medium, improving the overall sensor quality.3

REFERENCES

- A. Mignot et al., Optics Lett. 34(1) p. 97 (Jan. 1, 2009).

- S. Schwartz et al., Phys. Rev. Lett. 97, p. 093902 (2006).

- A. Garnache and I. Sagnes, Proc. IEEE, CLEO Europe/IQEC 2007, Munich, Germany, paper CB-34-WED (2007).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.