Micro Beam Steering: Precision micro beam-steering systems simplify move to handheld instruments

Beam-steering components are an essential part of many optical systems, especially those with lasers. Moving mirrors, prisms, lenses, and diffractive gratings are common optical methods to steer the output from collimated or noncollimated light sources in multiple rotational axes. Typical commercial beam-steering methods include nested gimbals that move a single mirror, fast steering mirrors that use two or three short-range parallel linear actuators to tilt a single mirror, two-mirror systems that use orthogonal galvanometer-mirror modules, and coaxial transmissive Risley prisms with independent rotation around the optical axis.

Newer beam-steering devices use microelectromechanical systems (MEMS) and microelectronic fabrication methods to create highly miniaturized devices. These include silicon arrays containing millions of tiny mirrors that are individually switched between two angular positions,1 liquid-crystal optical phased array (OPA) beam-steering systems,2 and silicon mirrors rotated in two axes using gimbal-less flexures and electrostatic or magnetic actuation.3

When using these MEMS devices, it is a significant challenge to create correspondingly small drive and control electronics to achieve a truly miniaturized beam steering system. Additional challenges include achieving high precision and linearity, and incorporating the ultrahigh-reflectivity optical coatings necessary for use with high-power lasers.

A fully integrated and miniaturized "point-to-point" beam steering system bypasses the issues with MEMS-based approaches and addresses the needs of many emerging markets in medicine and industry, specifically those that require:

- Range of motion greater than 10° for one or two axes

- System volume of less than 3 cm3

- Ability to use battery power with no internal voltage boost

- Ability to hold position without using power

- Angular precision less than 1 mrad with absolute position measurement

- Step-and-settle times less than 1 ms for small angles

- Mobile-phone robustness for surviving temperature, shock, and humidity in field use

- Embedded controller for small size and ease of system integration

- Options for high-efficiency optical coatings and materials for use with high-power lasers

For this discussion, "point-to-point" solutions are emphasized, where dynamic scanning is limited to less than 100 Hz. This contrasts with video-display devices with resonant scanners capable of video scanning rates of a few kilohertz.

Healthcare applications include diagnostic instruments, cell cytology, surgery, and micromanipulation. Industrial applications include remote sensing, optical image stabilization, hand-tremor cancellation, lidar, free-beam and optical-fiber communications, 3D measurements, and spectroscopy. For all these applications, a truly portable and handheld instrument requires a unique approach to packaging integration and component selection in developing the motion system.

Mechatronic modules: motors, drives, sensors, and more

Recent advances in piezoelectric mechanical drives have engendered a new class of components that enable incredibly small beam-steering solutions. Ultrasonic piezoelectric motors are a great match for beam-steering applications. The newest piezo motors operate directly from battery voltage and are only a few millimeters in size.4 Compared to electromagnetic actuators and electrostatic actuators, piezo motors provide much higher torque and excellent angular resolution and hold position without power.

Complementing these new piezo motors are piezo-motor-drive application-specific integrated circuits (ASICs). These ICs are even smaller than the piezo motor, and directly switch the battery voltage at ultrasonic frequencies under digital control. Finally, tiny ASIC position sensors are now available with a precision of less than 1 mrad.5

Creating miniaturized beam-steering systems from these tiny components requires a good deal of specialized knowledge. Skill and experience in micro-mechatronic systems engineering is needed to integrate the actuator, driver, sensors, mechanisms, optics, high-speed microcontroller, and embedded closed-loop firmware. The payoff is an all-in-one integrated system with an embedded controller that requires no separate electronics and interfaces directly with the instrument's system processor or a computer. The inputs use 3.3 VDC power and serial peripheral interface (SPI) or inter-integrated circuit communications (I2C) serial links for communication and control. Operating (moving) power is less than 1 W and zero power is needed to hold position. To further reduce power consumption, a programmable sleep mode maintains mirror positions during sleep mode.

Two-mirror micro beam steering

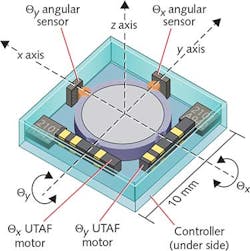

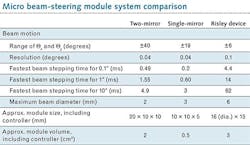

A two-mirror beam-steering system from New Scale Technologies6 is shown in Fig. 1, with specifications summarized in the table. Two mirrors independently rotate on orthogonal axes to produce ±40° beam deflection. This design is a highly miniaturized version of a conventional galvanometer ("galvo") beam-steering system that uses electromagnetic actuators.7 In this miniature module, the actuators are UTAF piezoelectric motors. This module has a volume of 2 cm3 with a largest dimension of 10 mm including the laser source.

A two-mirror system provides the largest range of motion, but does require a collimated laser beam with a diameter of less than 2 mm. The mirror reflectivity is selectable. Aluminum- or silver-coated mirrors provide reflectivity of greater than 90% for a 350–4000 nm wavelength range. For these mirrors, continuous-wave (CW) power should not exceed 10 mW, while a pulsed laser output minimum should have a duration of no less than 1 μs, to avoid exceeding laser-damage thresholds. Alternatively, mirrors with gold coatings can provide operation to a 20 μm wavelength. Dielectric coatings can be used for higher-power CW or short-pulse applications.

Single-mirror micro beam steering

Figure 2 depicts a single-mirror beam steering module with specifications summarized in the table. This simple and compact design has a single pivot point just below the mirror center. The x and y axes are in the plane of the mirror and the z axis is orthogonal to the mirror surface. Two UTAF motors, located 90° apart, tangentially drive the outer edges of the mirror. The single point friction contact of each motor does not restrict the orthogonal rotation axis and enables independent mirror rotations without a nested gimbal mechanism.The θx and θy axis rotations are measured by position sensors mounted 180° across from the respective motors. All drive and control electronics reside on a rigid printed-circuit board (PCB) beneath the mirror assembly. The module is 5 × 10 × 10 mm in size.

This single-mirror system provides the smallest size and the fastest step-and-settle time. Noncollimated beams with a diameter of up to 3 mm at the mirror surfaces can be used. The range of motion is smaller than the two-mirror system. A typical arrangement has the nominal beam incident angle at 45° from the z axis and the reflected exit beam parallel to the z axis. The mirror reflectivity is selectable in the same manner as for the two-mirror system discussed above.

Micro Risley prism beam steering

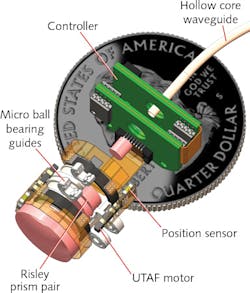

Figure 3 shows a Risley beam-steering module, with specifications summarized in the table. This design is used in an endoscopic laser scalpel. The transmissive optics direct a converging high-power laser to locations and patterns selected by the surgeon.8,9This highly miniaturized module integrates two coaxial Risley prisms that independently rotate around the optical axis. The laser beam can be up to 6 mm in diameter and is transmitted through both prisms. The combination of the absolute angles of each prism determines the output direction of the beam. This design is intrinsically long and thin with a straight optical path that makes it ideal for endoscopic insertion and manipulation.

The dual-wedge Risley design steers an incident beam over any point in a circular area with a diameter twice that of the single-wedge scan. The straight, clear aperture delivers high transmission and optomechanical simplicity. It is smaller, uses less power, and weighs less than gimbaled mirror systems.

Each optical prism is supported by micro ball-bearing guides with low friction and wobble. UTAF piezoelectric motors frictionally drive the outside diameter of each prism, enabling continuous bidirectional rotation with ±0.35° resolution and no jitter.

This transmissive in-line optical design accommodates the highest laser power levels of the three designs, and has the largest volume at 3 cm3. The larger mass and unique optical design, with nonlinear conversion of the prism rotation angles to beam angles, also reduces the step-and-settle times.

Integrating new piezoelectric and microelectronic components for actuation, sensing, and control into tiny modules requires specialized mechatronic skills and experience to achieve maximum and reliable performance. The resulting modules are easily integrated into optical instruments. This new class of miniature optomechanical beam-steering modules enables emerging applications in handheld, portable, and mobile instruments.

Compared to MEMS-based approaches, the piezo modules have fully integrated electronics to simplify system integration and achieve a smaller total system size, and offer greater flexibility in optical materials and coatings. These motion systems are allowing instrument designers to shrink tabletop-sized systems down to smaller devices without sacrificing performance, move analytical instruments out of the lab and into the field, and open new markets for medical and industrial analytical instrumentation.

ACKNOWLEDGEMENT

UTAF is a trademark of New Scale Technologies.

REFERENCES

1. See https://www.ti.com/.

2. D. P. Resler et al., Opt. Lett., 21, 9, 689–691 (1996).

3. See http://bit.ly/1SEKLrD.

4. D. Henderson and Q. Xu, "Semi-resonant driving systems and methods thereof," U.S. patent #7,786,648 (Aug. 31, 2010).

5. See http://bit.ly/1KBmgsI.

6. See http://bit.ly/1PQFLBk.

7. See http://bit.ly/1AwB3SD.

8. E. Kiesler, "Out of the lab and into the world: the endoscopic laser scalpel," Memorial Sloan Kettering Cancer Center blog (Dec. 1, 2011); see http://bit.ly/1AAFI5y.

9. D. Henderson, "Bringing image-guided laser surgery to endoscopy," Medical Design Technology (Oct. 2013); see http://bit.ly/1dAjnLE.

About the Author

David Henderson

Founder & CEO, New Scale Technologies

David Henderson is a technology innovator, experienced business leader, and proven team builder. He has more than 35 years of experience in engineering, new product introduction, worldwide market development, and profitable business operations. David’s technical expertise is mechanical and precision systems engineering. He has published or presented numerous papers and has been awarded more than 20 patents, including patents for the SQUIGGLE at UTAF piezoelectric motors.

Before founding New Scale in 2002, David was director of the positioning product division of Burleigh Instruments (now EXFO), where he achieved 300% revenue growth with 20% EBITA from 1994 to 2000. He has prior experience as a program manager and mechanical engineer with Contraves USA.

David has a BS in Mechanical Engineering and MBA from Carnegie Mellon University. He serves as chairman of the New Scale Technology board of directors.

Jeff Kramer

Jeff Kramer is president and CEO of Enetics (Victor, NY); he previously served as vice president, business development at New Scale Technologies (also in Victor, NY) in 2015-2016.