Motion Control: Active piezo shims improve precision of optical assemblies

Precision machine tools, laser processing equipment, and forms of optical apparatus are often complex assemblies of different components. The alignment of these components is critical for the overall precision and function of these systems. If a target dimension between two components changes, then readjustment may be unavoidable. This can be the case when a machine is put into operation after delivery and tolerances are out of spec because of initial setting processes. Long-term creep or temperature changes can also have the same effect.

Optical measuring facilities, astronomical devices, wafer-processing machines, chip holders, and positioning systems for heavy-precision industrial applications are frequently affected by these issues. Differences on the order of a few microns, or less, can exceed limitations. The classical solution to fix such differences is to use shims, ground exactly to the required tolerances. The fact that shims have to be installed—often in hard-to-reach locations—can be a time-consuming and expensive disadvantage. Furthermore, this type of adjustment is not infinitely possible, and once the dimension has been fixed, it can be very difficult to change it afterwards.

Engineers may often have wished for the possibility of changing the thickness of such shims remotely to bring the system back into perfect alignment. With the advent of a new technology, this is no longer wishful thinking. In such cases, piezo-based active shims, or spacers, are a practical solution for the adjustment process. Once installed in the machine, the active shims can readjust the gap between two components at any time with nanometer precision (see Fig. 1).

Active shims, such as the PIRest piezo-based shim, are a novel alternative, simplifying and speeding up the adjustment process considerably. Because of the piezo element’s high resolution down to the nanometer range, it covers applications in classical mechanical precision engineering, as well as the alignment of optical components in astronomy, semiconductor manufacturing, and materials research, such as that conducted with beam-line instrumentation.

Set and forget: high load capacity

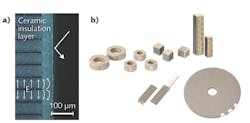

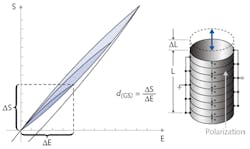

The piezo-based spacers are installed in the machine during its construction. They are available in virtually any shape and size, such as plates, rings, and cylinders, and can be designed to hold heavy loads of several tons (see Fig. 2).The concept of a piezo ceramic actuator is well understood. Displacement is dependent on electric charge and by changing the drive voltage, the actuator will expand or contract in real time (see Fig. 4). While drawing negligible power in steady state operation, the actuator will slowly recede to its zero position when the power source is removed.

Active shims with nanometer resolution and long-term stability

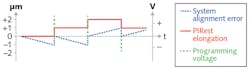

The displacement of a PIRest actuator is programmed with a specific control tool and remains constant after disconnect from the power source (see Fig. 5). This is comparable to a self-locking, screw-type actuator, but at much higher precision and without creep.The displacement stability depends only on the change of ambient temperature. Long-term tests in an environment staying within a ±1 K temperature change using an actuator with a 10 μm nominal adjustment range indicated a position drift of less than ±100 nm, irrespective of the displacement. As an option, the active shims can be equipped with a temperature sensor. Skillful combination of the active shims makes it possible to adjust in up to six degrees of freedom.

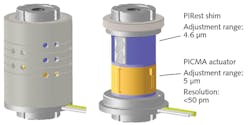

A voltage connector for programming is provided with the active shim that needs only to be connected shortly for each respective adjustment. The necessary cables can be considered during design of the machine and become a permanent part of the system. After adjusting, the desired position remains stable without power and the power supply can then be disconnected.If required, active shims can also be combined with classical piezo actuators (see Fig. 6). Typical applications for these types of hybrid systems include dynamic vibration compensation, readjusting the focal plane during an optical measuring or scanning process, and controlling a laser beam in metrology systems or materials processing.

Mathias Bach | Head of Piezosystems Product Division, PI (Physik Instrumente)

Mathias Bach is head of the piezosystems product division at PI (Physik Instrumente; Auburn, MA).

Stefan Vorndran

Stefan Vorndran is VP of marketing at PI (Physik Instrumente; Auburn, MA).