Photonics Products: Laser-cooling equipment: Keep your laser-diode system cool, whatever the power

To operate within temperature specifications, virtually any high-power laser must be actively cooled, whereas many low-power lasers get by with passive cooling via either some sort of heat sink or just natural airflow (picture, for example, a lowly helium-neon laser resting in a lab mount with no obvious cooling mechanism in sight). Laser diodes (LDs) are a special case: their small size means that even low-power emitters require a well-thought-out cooling configuration.

All LDs have the active emitting semiconductor chip mounted on a heat-conductive mount, usually metal. As a result, all LDs are, at their core, conductively cooled. For the lowest-power LDs (and many pulsed LDs), conductive cooling by itself (often, for small devices, paired with convective air cooling) is adequate. Step up a bit in output power and a LD may require the addition of a thermoelectric cooler (TEC). For the highest output powers, such as those produced by diode bars and arrays for materials processing, water cooling is necessary.

The type and complexity of cooling needed for a LD depends crucially on the application. For example, a telecommunications LD may require an integrated TEC for stability, whereas a low-power LD used for beam-interruption sensing needs nothing special. Consequences of inadequate laser-diode cooling can include degradation in beam quality, excessive shift in center wavelength, and in the worst cases, catastrophic failure of the LD.

The many LD and cooling equipment manufacturers existing today, not to mention the variety of LD cooling hardware produced by these manufacturers, lead to the fact that a short article cannot include more than a tiny portion of the available products. Thus, only a small sampling of what is available can be presented here.

Thermoelectric cooling

As previously mentioned, the lowest-power LDs (a few milliwatts or less) usually don’t need special thought given to cooling unless they are mounted in a thermally insulated environment. For laser output power ranges in the tens and hundreds of milliwatts, cooling starts to become more important, especially for lasers that require good control of beam quality—here, thought given to heat-sink design is a benefit. For cooling of small diode sources that emit up to on the order of 10 W, TECs can provide compact, efficient cooling with no moving parts. (A small fan is an option, though.)

Thorlabs (Newton, NJ) produces a series of TEC LD mounts (LDM21) intended for single-emitter diodes in cans with different pin configurations and optical outputs of up to 2 W; these are complete mounts with electronic control and the option of collimation of the output beam. A higher-power TEC version (LDM56) handles LD output powers up to 8 W and is made to attach to a flexure mount if desired. All of the company’s TEC LD mounts are compatible with standard threaded posts, as well as threaded optical components such as collimating optics.

In addition to similar lab-style LD mounts, Newport (Irvine, CA) makes TEC mounts (LDM-4983T) for common 13-pin, 7-pin, and other butterfly telecommunications LD packages, as well as other LD package types that include dual-in-line (DIL), mini-DIL, and connectorized LD package versions. It should be noted that these TEC mounts are intended to be used with a telecommunications LD that has its own internal TEC. Therefore, the external mount is used for applications requiring high temperature stability or for testing laser diodes at a wider temperature range than can be accomplished with the LD’s internal TEC.

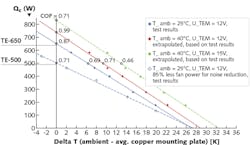

Thermoelectric cooling technology is not limited to single-emitter LDs, as higher-capacity TEC units, such as those produced by AMS Technologies (Martinsried, Germany), can cool LD modules emitting hundreds of watts of power (see Fig. 1). The company’s highest-capacity TEC unit (TE-650) has a nominal cooling capacity of 650 to 830 W. Its copper heat sink, which can be drilled to any LD hole pattern, has a mounting surface 200 × 190 mm in size and is air-cooled by fans that push out a volume of 700 m3/h. Thermal grease or graphite foils provide the thermal interface between the LD and the cooled mount.

Cooling for high powers

For materials processing ("direct diode" laser systems, as well as pumping of DPSS and fiber lasers), as well as a few other uses (military-laser pumping, drilling oil wells, and perhaps someday propelling laser-sail spacecraft), LD-based systems can produce optical output powers well into the multikilowatt regime. Such systems demand the ultimate in cooling capacity.

Lasertel (Tucson, AZ) makes a series of fluid-cooled LD arrays that produce continuous-wave (CW) powers to 2500 W or quasi-CW powers to 25 kW. The monolithic design of the units allows them to be cooled with plain filtered water rather than the more-expensive deionized water (alternative non-water cooling fluids can be used also). The units, which have hard-soldered construction, can be added together to create larger modules that emit up to 1 MW of power with integrated cooling. Emission wavelengths range from 760 to 1700 nm.

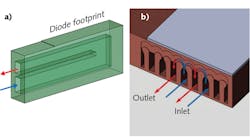

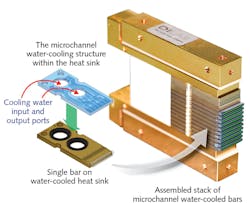

Many high-power LD units and systems are cooled using microchannel or micro-impingement coolers, in which water is forced through many very small channels in a metal block upon which the LDs are mounted. While the traditional channel configuration is end-to-end through the block, Micro Cooling Concepts (MC2; Huntington Beach, CA) specializes in the design and manufacture of alternate configurations (see Fig. 2). One microchannel geometry, which works well for cooling of single-emitter LDs, has a flow path that makes a 180° turn under the LD. A high-power micro-impingement cooler combines impingement heat transfer with manifold microchannel designs—MC2 says that off-the-shelf coolers can reach thermal resistances as low as 25 K-cm2/kW, with experimental coolers reaching 18 K-cm2/kW.For high LD powers and water-flow rates, a closed-loop water circulation system conserves water and thus costs. Such systems are often cooled by laser chillers, which can operate via either TEC or via other types of refrigeration, predominantly vapor compression. Opti Temp (Traverse City, MI) makes various types of refrigeration chillers, including portable (rollable) liquid- and air-cooled, rack-mount liquid- and air-cooled, and large air-cooled remote floor-mounted condensers. The remote units have cooling capacities up to 35 kW and operating temperature ranges up to 90°C.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.