Photonics Products: Vibration Control: Hexapods provide precise positioning in six axes

The hexapod is a simple and elegant way to provide six-degrees-of-freedom (6DoF) position control of a test platform relative to a base. If the movable platform and stationary base are considered rigid triangles for the sake of discussion, the structure of the archetypal hexapod is actually akin to an octahedron, with six side edges extensible in length and three top and three bottom edges rigid (although some real hexapods don’t look much like octahedrons).

The result is what mechanical engineers call a statically determinate structure. Such a structure automatically adjusts to the change in length of a strut (in reality, a linear actuator) without stress in the other components by changing shape and position. With properly calculated changes in various actuator lengths, the test platform can be moved in x, y, z, θx, θy, and θz independently or in combination. Because of their complexity, these motions are usually coordinated by computer software. Depending on the precision of the linear actuators, precision of the hexapod can be in the nanometers range.

Hexapods, which are also called Stewart platforms, are essential parts of many precision optics setups for science and industry. While this article cannot include more than a small portion of the available hexapod products, a representative sampling of what can be found is presented here. It should be noted that all manufacturers in this article make custom hexapods on request.

What makes a hexapod?

Hexapods are made in a wide range of sizes and ranges. Stefan Vorndran, vice president of marketing for Physik Instrumente (PI; Auburn, MA) notes that PI started designing precision hexapod motion platforms in the early 1990s for astronomical telescopes in Hawaii. Now, PI manufactures hexapods and related six-axis parallel motion systems for loads from 0.5 to 2000 kg—more than 100 models and variations are available. “All types provide submicron precision; some achieve nanometer precision,” Vorndran says. “Most hexapod applications require fast step and settle, with very high stability and precision (precision positioning hexapods), while some require continuous fast motion (motion hexapods).”

Brushless servo motors, linear motors, piezo linear motors, or stepper motors can be used in hexapods, Vorndran explains. Brushless motors provide high dynamics and long life, important for 24/7 applications. Linear motors provide the highest speed, but relatively low force compared to the size. Piezo motors provide subnanometer resolution and self-locking capabilities, so they are ideal for vacuum and nonmagnetic applications.

Ball screws, roller screws, lead screws, and direct drive (linear motor) systems are used for power transmission. Roller screws provide the highest stiffness and are self-locking, while ball screws are a good compromise for cost and speed.

Flexure joints (which have zero friction, backlash, and wear) are used in lower-load applications such as high-speed motion hexapods and ultra-precision hexapods, Vorndran says. For higher loads and robustness, cardanic (universal) joints with z-offset provide the best combination of stiffness and orientation-independent performance, but require more-advanced control algorithms to deal with the offset geometry (this means a fast controller that can provide millions of operations per second for precise, smooth six-axis path planning). Spherical joints may look like a good choice, Vorndran says, but for most applications they are not recommended because of their lower stiffness and directional dependency.

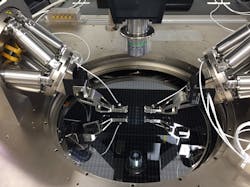

In one example, PI’s H-811.i2 compact hexapod provides 5 nm resolution, 34 × 32 × 13 mm x-y-z, and 20 × 20 × 41° rotary travel, and can carry a 5 kg load at a 20 mm/sec max. velocity. It uses brushless servo motors and low-friction ball screws. Target applications are alignment of optical lenses and fibers and silicon-photonics (SiP) manufacturing. The H-811 model contains an Ethercat-compatible controller that handles all coordinate transformations internally, as well as the math for the user-programmable pivot point and different tool/workpiece coordinate systems. A high-speed input for external instruments, such as optical power meters and firmware-based fast alignment routines, help speed up automated alignment processes.

Test and packaging of SiP devices require nanoscale alignments that cannot be performed using visual or mechanical references because the optical throughput itself must be optimized. SiP designs often incorporate multiple parallel optical paths with interacting inputs and outputs, all needing optimization simultaneously for economical and physical reasons. Size restrictions also dictate that the alignment apparatus be as small as possible. The capabilities of a compact, low-inertia 6DoF motion system such as the H-811 mechanics, controller, and software combination are key to advancing SiP production from planar test to packaging, Vorndran says (see Fig. 1).

Numerous functions for hexapods

Hexapods have more than one function as precision motion devices. Moog CSA (Reno, NV) produces hexapods and other multi-degree-of-freedom motion control systems for three primary applications: precision positioning, high-frequency motion simulation, and vibration isolation, explains Ryan Sneed, the company’s hexapod product manager.

Precision positioning hexapods typically use motor-driven roller screw actuators for quasi-static positioning or slow tracking and can achieve resolutions of better than 1 µm and 1 µrad. Payloads range widely from small sensors to 5000 kg mirrors for large ground-based telescopes, Sneed says. Motion-simulation hexapods incorporate voice-coil actuators and create motion and disturbance profiles with frequency content up to a few hundred hertz. Vibration-isolation hexapods rely on pneumatic struts with nearly frictionless air bearings and are used to reduce vibration levels from base disturbances on laser and optical systems. They can achieve 60 dB isolation across a target frequency band without the gravity-induced sag of soft mechanical springs typically used for isolation.

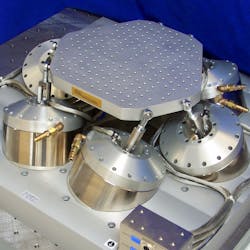

Sneed gives Moog’s HX-M350 as an example of a high-frequency motion-simulation hexapod that has filled a range of critical applications for optics and photonics. The voice-coil actuators support payloads up to 180 kg while achieving tip/tilt rotational ranges of ±2.5° and lateral and vertical translational ranges of ±25 and ±11 mm, respectively. Real-time platform-based control allows for control-system tuning on individual hexapod axes rather than more limiting control over only the actuator axes. Reflective memory interfaces permit rapid data transfer for hardware-in-the-loop missile-tracking co-simulations where high-frequency disturbances replicate in-flight jitter conditions.

The HX-M350 also simulates 6DoF on-orbit vibration environments for satellite optical sensors compared to traditional shaker systems that are limited to motion in one linear axis at a time (see Fig. 2). Testing camera-image stabilization algorithms or ensuring product integrity are other examples where this technology finds application, Sneed says.High thermal stability

Symétrie (Nimes, France) makes high-precision positioning and dynamic-motion hexapods from 68 mm to 4 m height, says Anne Duget, Symétrie’s marketing and sales manager. Precision positioning systems are used to align mirrors or samples on beamlines and mirrors on satellites or on telescopes at submicron resolution, she explains, while motion systems that simulate the motion of a boat, truck, tank, and aircraft are used to test electro-optics systems that will be onboard later with a maximum speed of 2 m/s and 4 g acceleration. Payloads can vary from a few grams to tens of tons. “Due to the six actuators of the hexapod, it is easy to spread the payload weight over them,” Duget says.

Symétrie’s high-performance hexapod, called ZONDA, meets applications requiring high precision, heavy load, and large travel range, Duget says. Designed to position payloads up to 400 kg with a resolution of 50 nm, the ZONDA hexapod has travel ranges with 400 mm in x and y, 300 mm in z, and 40° in θx, θy, and θz. Its high thermal stability is because of the integration of Invar material, linear absolute encoders, and “particularly rigid joints,” Duget adds. Invar has a very low coefficient of thermal expansion of 1 µm/m/°C when compared to steel (11 µm/m/°C) or aluminum (23 µm/m/°C).

“The ZONDA hexapod can be vacuum- or clean-room compatible,” Duget says. “It is often used to calibrate space optical instruments (Airbus Defence and Space, Bertin Technologies, Liege Space Center, OHB (see Fig. 3), Thales Alenia Space, and others) or to align mirrors or samples on beamlines (for example, the European Synchrotron Radiation facility).”

“Traditional hexapods from Europe have microns of backlash, which are not accounted for in the precision spec sheets but need to be, since hexapod legs are in compression and tension with every move,” Hennessey states. “The ALIO HH has 100 nm of 3D precision in all areas of the work zone, whereas traditional hexapods are in the hundreds of microns (not nanometers), which is assumed from the data sheets for unidirectional z motion only.” The HH is scalable from 10 mm to more than 1 m; typical 3D point repeatability within the work zone is <100 nm, Hennessey says.

As for applications, Hennessey describes the assembly of 4K lenses [lenses for cameras with 4K resolution] as a perfect example of the HH capabilities for precision assembly. “For high-end 4K lenses and the future 5K lenses, it might be the only motion system capable of these tasks due to the increased precision needed for 5K resolutions,” he says. “The real win for ALIO is the 5K lens in the pipeline, which our HH will be the only precision platform to enable. I think some of the reasons 5K is not mainstream is that manufacturers are trying to get it done with old motion systems used for 4K.”

4K lenses have a precise curved lens that needs to be bonded on a CCD, Hennessey explains. “The issue solved by the ALIO HH is the precision and tool center-point programming needed to accurately rotate on the same curve as the lens to find optimal assembly, then move to the bonding point with tool center-point precision (TCP), changing the coordinate system for making the motion to bond as the path. Hexapods manufactured in Europe lack the TCP to change the coordinate system; thus, they make irregular motions one axis at a time to the bonding point, which can break the device and/or create low yields due to imprecise bonding location.”

Hexapods have an error quotient that is additive for each axis. For a HH, Hennessey notes, the motion of a move in x will only generate one error of one axis, not all six, thus programmable path motion or moving back to best light delivers orders-of-magnitude more precision than any five- or six-axis motion platform, he says. The issue of multiple tool center points in one program application can be solved seamlessly with nanometer precision, as in lens and CCD assembly.

Hexapods excel for pointing applications

Hexapods made by Aerotech (Pittsburgh, PA) have 6DoF positioning and come in two sizes: the larger model (HexGen HEX500-350HL) positions loads up to 200 kg, while the smaller (HexGen HEX300-230HL) positions loads up to 45 kg, says R. J. Hardt, Aerotech’s business development manager. Both are actuated with six individual struts that are built with preloaded bearings and ball screws. The smaller version has linear travel to 110 mm and angular travel to 40°, with minimum incremental motion to 20 nm in x, y, and z and 0.2 μrad in θx, θy, and θz. The larger version has linear travel to 60 mm and angular travel to 30°, with minimum incremental motion to 20 nm in x, y, and z and 0.2 μrad in θx, θy, and θz.

“The HEX500-350HL is ideal for applications in x-ray diffraction, sensor testing, and high-force device manipulation,” Hardt says. “It is driven by AC brushless, slotless servomotors that maximize device lifetime and performance. The servomotors are directly coupled to the actuator ball-screw, enabling increased drive stiffness, higher positioning accuracy, and better minimum incremental motion when compared to competitive designs that use belts, gearheads, or compliant couplings. The strut pivot-joints are engineered to provide low friction and high stiffness.”

The HEX500-350HL, Hardt explains, was of particular use in a pointing application while testing a sensing device. The device required the hexapod to position a 1-m-long tangent arm that carried the sensor. Thus, the point of interest was over a meter away from the moving platform of the hexapod. Using Aerotech’s motion controller, calibration techniques, and kinematic tool-point commands, the sensor was manipulated at a precision of just a few microns at the point of interest. Without this approach, the user would have been forced to deploy a much more complicated—and likely more expensive—serial kinematic-based system, according to Hardt.

Hexapods for every purpose

Hexapods from Newport (Irvine, CA) fall into three general families: high-precision, high-accuracy, and high-load. The high-precision versions are light and stiff and have no moving cables, while the high-accuracy hexapods have guaranteed x, y, and z accuracy values and guaranteed pitch and yaw deviations during axial motion. The high-load hexapods have centered load capacities up to 450 kg, along with high speed and long-range travel. The company also makes controllers, as well as vacuum-compatible versions of its hexapods.

For More Information

Companies mentioned in this article include:

Aerotech

Pittsburgh, PA

ALIO

Arvada, CO

Moog CSA

Reno, NV

Newport

Irvine, CA

Physik Instrumente (PI)

Auburn, MA

SmarAct

Oldenburg, Germany

Symétrie

Nimes, France

DISCLAIMER: While we try to include information from the broadest possible number of companies that manufacture the products featured in our Photonics Products series, because of limited word count as well as deadlines that cannot always be met by requested contributors, we cannot possibly include all companies and regret if your company is not included in our series.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.