Open-source 3D printing of optical mounts cuts costs and permits customization

Houghton, MI--To many, "open source" refers to software that is usually (though not always) nonproprietary, easily modifiable, and free. The term "open source" can also be applied to hardware—for example, optical-mounting hardware, as recently introduced by a lab at Michigan Technological University (MTU).1

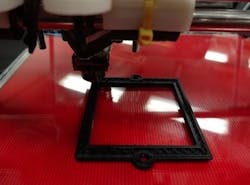

In a further twist, the hardware comes in software form, as downloadable files to be used with a 3D printer to build the final product. These 3D-printable mounting and other devices include lens holders, customizable chopper wheels, lab jacks, and optical rails—and even optics, in the form of a liquid-filled lens.

The additive-layer-manufactured components are made of plastic, which limits their precision (and limits them to use with low-intensity light), but they are intended to broaden the audience for optics (in education as well as research) rather than to replace currently available precision components. Another interesting point: the components an be printed on the so-called RepRap 3D printer, which is an open-source printer that—yes—can be at least partially manufactured using another RepRap. (The scary part is when they start independently self-replicating.)

Free library

Joshua Pearce, an associate professor of materials science and engineering and electrical and computer engineering at MTU, explains, “This library operates as a free, flexible, low-cost tool set for developing both research and teaching optics hardware.”

Pearce’s lab used OpenSCAD, an open-source computer-aided design software tool, to make the designs customizable. The electronics and controls are based on the open-source Arduino microcontroller environment.

The study found cost reductions of generally more than 97%, with some components costing only 1% of the market price for optical products of similar function. “For example, commercial optical rail sells for around $380 per meter, and you can build an open alternative with printed parts for less than what you would pay in sales tax,” says Pearce. “And there is no sales tax, shipping costs or waiting for parts to come in stock or ship.”

In one example of potential cost savings, to outfit an undergraduate teaching laboratory with 30 optics setups costs less than $500 using the open-source optics approach, compared to $15,000 for commercial versions.

Customizability

“Saving money is nice, particularly for cash-strapped schools, but the real advantage of this approach is it enables researchers to fabricate custom optics equipment in house. You get exactly what you need for your experiments, even if they are not commercially available,” says Pearce, “This is the future of scientific equipment; we have only just started.”

Examples of 3D-printable optical mounts, along with downloadable designs, can be found at http://www.thingiverse.com/jpearce/collections/open-source-optics.

REFERENCE:

1. C. Zhang et al., “Open-Source 3D-Printable Optics Equipment,” PLOS One (2013).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.