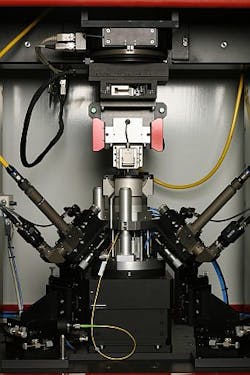

Nanosystec alignment and fiber pigtailing stations work with alignment in X, Y, and Z

NanoWeld-RGB alignment and fiber pigtailing systems suit volume production of fiber-pigtailed packages down to 405 nm. The systems work with 20 nm resolution for alignment in X, Y, and Z in order to achieve less than 0.1 µm deviation in bidirectional repeatability. A rotational axis orients polarization, a compliance tool provides a force-free and uniform contact zone between surfaces, and an automated procedure with single-spot welds adjusts the mechanical position back to maximum coupling efficiency.

Nanosystec

Gross-Umstadt, Germany

[email protected]

-----

PRESS RELEASE

NanoWeld-RGB provides durable Single Mode Fiber Pigtailing for visible Lasers

The NanoWeld-RGB alignment and fiber pigtailing stations combine precision alignment in the submicron regime with a low weld shift assembly procedure. Optimized to perfection for data and telecom diode lasers over years, NanoWeld-RGB is now successfully used for the volume production of fiber pigtailed packages in the visible regime – down to 405nm.

Due to the tiny core diameter between 3 and 6 micrometers in the visible range, the alignment to reach maximum coupling efficiency between the laser assembly and the optical fiber is extremely demanding. The NanoWeld-RGB systems work with 20nm resolution for the alignment in X, Y and Z in order to achieve less than 0.1 micrometer deviation in bidirectional repeatability. A rotational axis orients the polarization.

A unique compliance tool in the NanoWeld-RGB systems provides a force-free and uniform contact zone between the surfaces to be welded together. Therefore, the power shift due to the unavoidable shrinking of the melted material is minimal. An automated procedure with single spot welds adjusts the mechanical position back to maximum coupling efficiency.

The automated processes on the NanoWeld-RGB allow repeatable volume manufacturing with predictable cycle times and results. Because of its excellent yield with practically 100% and its high throughput, the investment is safe and opens new application fields for visible lasers and laser diodes with fiber pigtail.

nanosystec GmbH

Marie-Curie-Strasse 6

64823 Gross-Umstadt, Germany

Website: www.nanosystec.net

E-mail: [email protected]

Phone: +49 (6078) 782540

-----

Subscribe now to Laser Focus World magazine; it's free!