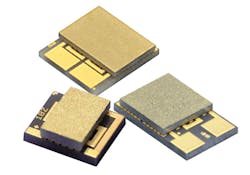

Laird Technologies thermoelectric coolers are gold-metalized for dense optoelectronics

The eTEC Series thermoelectric modules use thin-film technology that gives them 10X heat-pumping density per unit area over conventional bulk thermoelectric technology. The ceramic substrates are gold-metalized for embedding into densely packed optoelectronics. Available models have heat-pumping densities from 75 to 90 W/cm2 at a 25°C ambient temperature.

Laird Technologies

St. Louis, MO

[email protected]

-----

PRESS RELEASE

Laird Technologies Releases New eTEC™ Series Thermoelectric Module Product Line

New High Power Density Thin Film Modules Provide Precise Temperature Stabilization for High Powered Optoelectronics and Laser Diode Application

St. Louis, Missouri, USA – Laird Technologies, Inc., a global leader in the design and supply of customized performance-critical components and systems for advanced electronics and wireless products, today announced the release of its eTEC™ Series Thermoelectric Module (TEM) product line.

The eTEC™ Series of TEMs enable high powered optoelectronics to maintain peak performance by stabilizing the temperature of the device during operation. The modules are assembled using thin film technology that enables the TEMs to have ten times the heat pumping density per unit area than conventional bulk thermoelectric technology. The ceramic substrates are gold metallized to allow the product to be embedded into densely packed optoelectronics.

“As next generation packaging shrinks in size, conventional bulk technology becomes more of a design constraint due to its large package size,” said Andrew Dereka, Laird Technologies Product Manager. “Thin film technology provides our customers with more flexibility to optimize package design and keep optics stable in temperature fluctuating environments.”

The thin film eTEC TEMs have heat pumping densities ranging from 75 to 90 W/cm2 at an ambient temperature of 25°C. The new models include:

HV14,18,F0,0101,GG – 1.4 Watts in 1 mm2

HV37,48,F2,0202,GG – 3.7 Watts in 6.9 mm2

HV56,72,F2,0203,GG – 4.8 Watts in 10.2 mm2

Constructed with Bismuth Telluride thin film technology and thermally conductive Aluminum Nitride ceramics, the eTEC™ Series is designed for higher voltage and lower, sub 10 Watt heat pumping applications. Other features include RoHS compliance, pending Telcordia Compliance and gold metallization for solder ability to mating substrate surfaces. As an industry leader in high-performance and cost-effective Thermal Management Solutions, Laird Technologies provides the knowledge, innovation, and resources to ensure exceptional thermal performance and customer satisfaction for applications in the medical, analytical, telecom, industrial, and consumer markets.

Contact Information

For additional information, visit http://www.lairdtech.com or contact us at:

Americas: +1-888-246-9050 option 2

Europe: +46-31-704-67-57

Asia: +86-755-2714-1166 x374

e-mail: [email protected]

About Laird Technologies, Inc.

Laird Technologies is a global technology company focused on providing components and solutions that protect electronic devices from electromagnetic interference and heat, and that enable connectivity through wireless applications and antenna systems.

Custom products are supplied to all sectors of the electronics industry including the handset, telecommunications, data transfer and information technology, automotive, aerospace, defense, consumer, medical, mining, railroad and industrial markets.

Laird Technologies, a unit of Laird PLC, employs over 9,000 employees in more than 46 facilities located in 16 countries.

-----

Subscribe now to Laser Focus World magazine; it's free!